Stacking device and loading machine

A stacking and racking technology, applied in the directions of transportation and packaging, loading/unloading, stacking of objects, etc., can solve the problems of large moving space, limit the stacking space range of the stacking device of the frame design of the loader, and increase the moving space. , to avoid the effect of overall instability and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

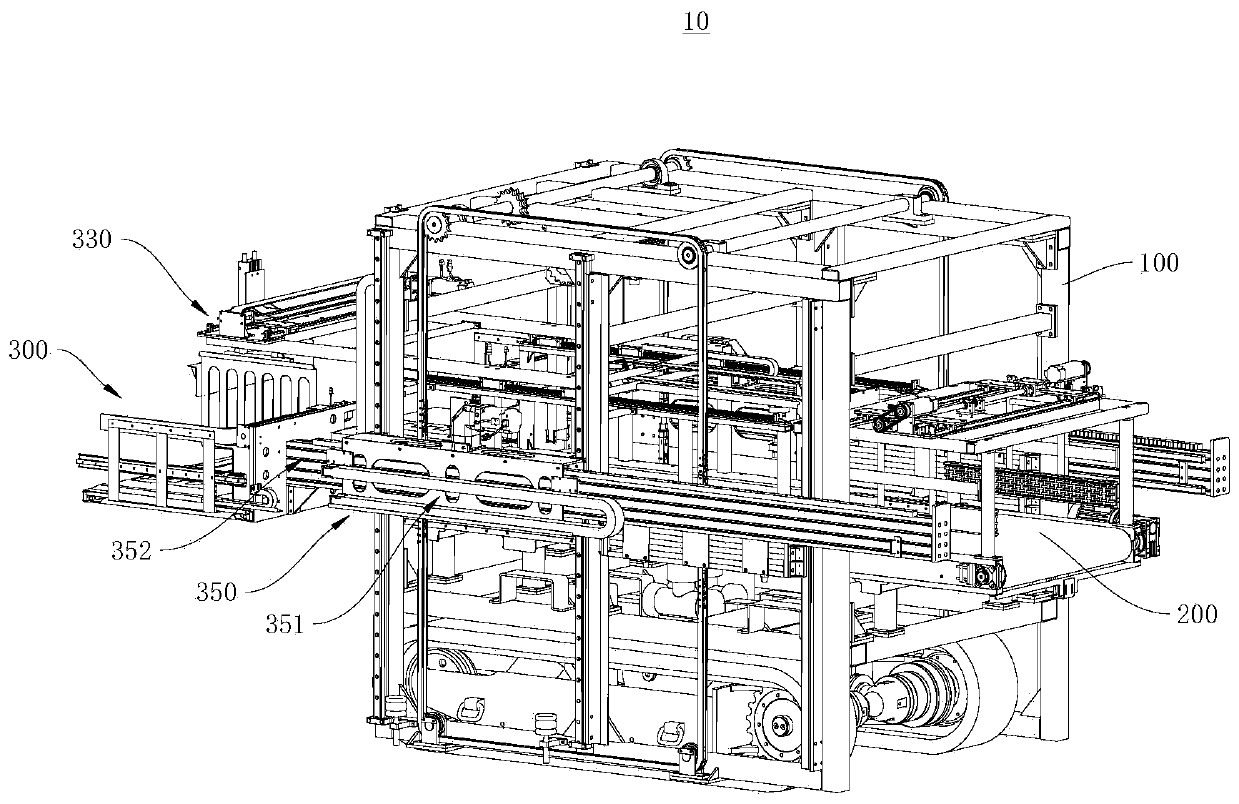

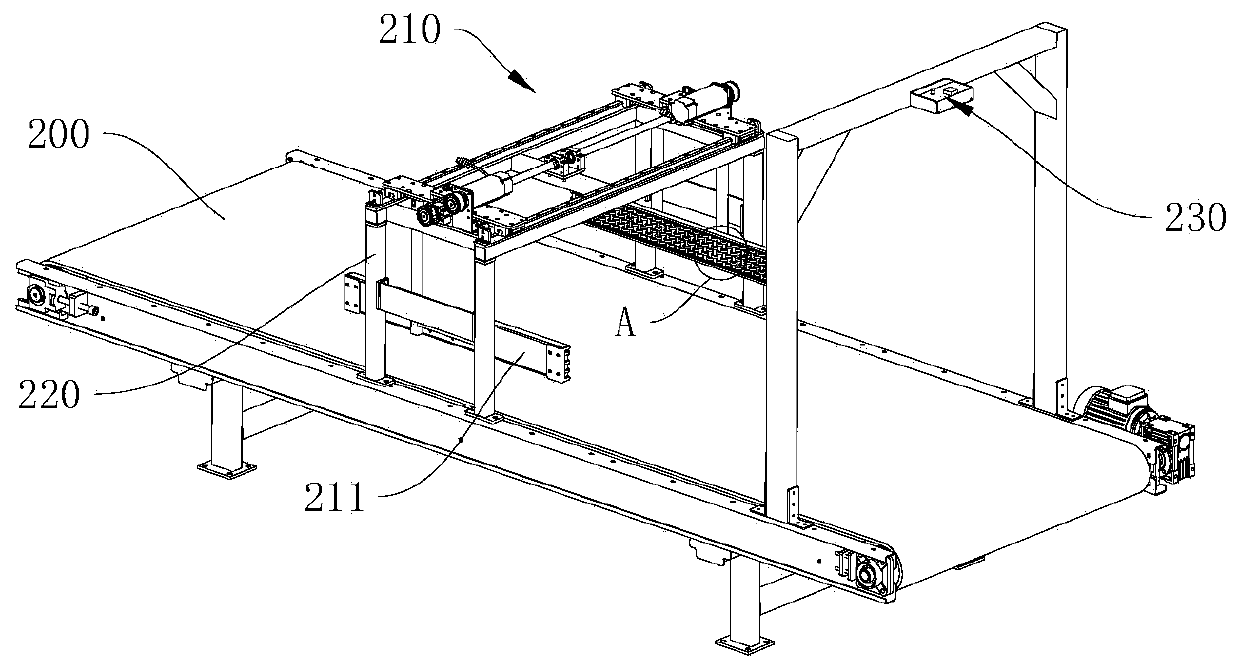

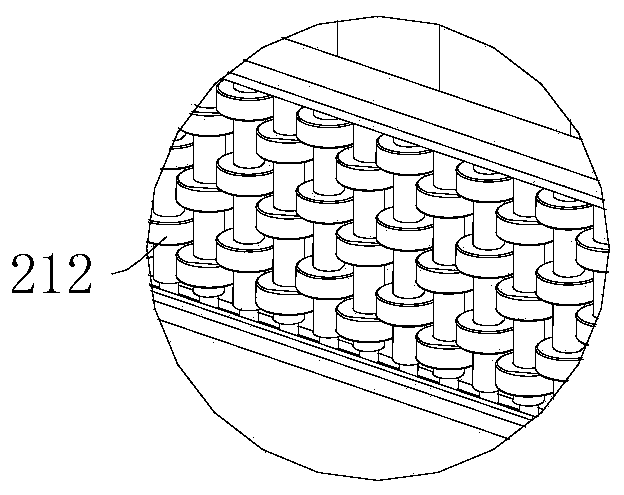

[0035] See figure 1 In this embodiment, a vehicle loading machine 10 is provided, which is used to store goods on the loading plane inside the vehicle compartment (not shown). Among them, the overall structure of the loading machine 10 is compact, which can improve the overall stability and expand the stacking range.

[0036] It should be noted that the loading machine 10 is used to be placed on the cargo plane inside the carriage, and can move on the cargo plane, so as to transport the goods to the designated position and store the goods in the designated position, thereby making The goods can be neatly stacked on the cargo plane. In addition, the loading machine 10 is connected to a conveying device (not shown) for conveying goods. The conveying device transports the goods from the warehouse or other places to the loading machine 10. The loading machine 10 can accept the goods conveyed by the conveying device and The goods are moved and stacked to the designated location.

[00...

no. 2 example

[0079] This embodiment provides a loading system (not shown), which uses the loading machine 10 provided in the first embodiment, and the overall structure of the loading system is compact, which can improve overall stability and expand Stacking range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com