Preparation method for 3D direct-printing grating printing product

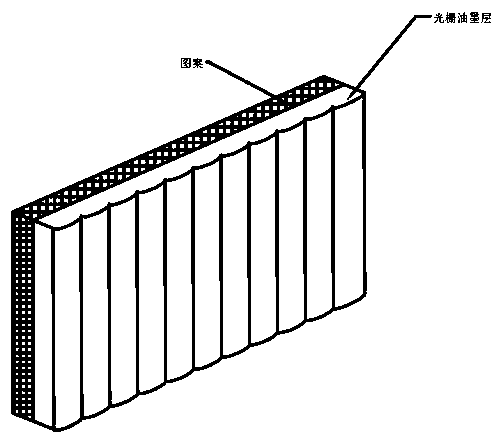

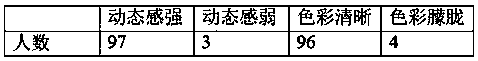

A printing and grating technology, which is applied in the field of 3D direct printing grating printing, can solve the problems of insufficient dynamic sense, easy blurring of patterns, high application cost, etc., and achieve the effect of glossy three-dimensional effect, high output precision, and pattern cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a 3D direct printing grating print, comprising the following steps:

[0026] (1) Plate making, according to the design drawings to make the printing plate, so that the output precision of the printing plate is 9500DPI, and the screen line number is 800LPI;

[0027] (2) Use the offset printing method to print the design pattern on the base paper, adjust the machine so that the dot shrinkage ratio of the pattern printing is 98%; at the same time, it is necessary to adjust the sharpness of the grating ink, 98% can prevent the printed groups from bleeding into each other The resulting pattern is not clear and looks unclean. After adding the grating layer, the visual color will expand to a certain extent, and it will shrink by 95-98% during printing, which can ensure that the visual pattern will be cleaner after adding the grating layer. , bright;

[0028] (3) Make a mold for grating ink, the resolution of the mold is 280LPI;

[0029] (4) printing gr...

Embodiment 2

[0035] A method for preparing a 3D direct printing grating print, comprising the following steps:

[0036] (1) Plate making, according to the design drawings to make the printing plate, so that the output precision of the printing plate is 9700DPI, and the screen line number is 700LPI;

[0037] (2) Use the offset printing method to print the design pattern on the base paper, adjust the machine so that the dot shrinkage ratio of the pattern printing is 95%; at the same time, it is necessary to adjust the sharpness of the grating ink, 95% can prevent the printed groups from bleeding into each other The resulting pattern is not clear and looks unclean. After the grating layer is added, the color will expand visually to a certain extent, and it will shrink by 95% during printing, which can ensure that the visual pattern will be cleaner and brighter after adding the grating layer. .

[0038] (3) Make a mold for grating ink, the resolution of the mold is 260LPI;

[0039] (4) Print...

Embodiment 3

[0045] A method for preparing a 3D direct printing grating print, comprising the following steps:

[0046] (1) Plate making, according to the design drawings to make the printing plate, so that the output precision of the printing plate is 9600DPI, and the number of screening lines is 750LPI;

[0047] (2) Use the offset printing method to print the design pattern on the base paper, adjust the machine so that the dot shrinkage ratio of the pattern printing is 96%; at the same time, it is necessary to adjust the sharpness of the grating ink, 96% can prevent the printed groups from bleeding into each other The resulting pattern is not clear and looks unclean. After adding the grating layer, the visual color will expand to a certain extent, and it will shrink by 95-98% during printing, which can ensure that the visual pattern will be cleaner after adding the grating layer. , brightly colored.

[0048](3) Make a mold for grating ink, the resolution of the mold is 260LPI;

[0049]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com