Vegetable cutting device

A cutting device and vegetable technology, applied in metal processing and other directions, can solve the problems of high energy consumption, slow labor speed and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

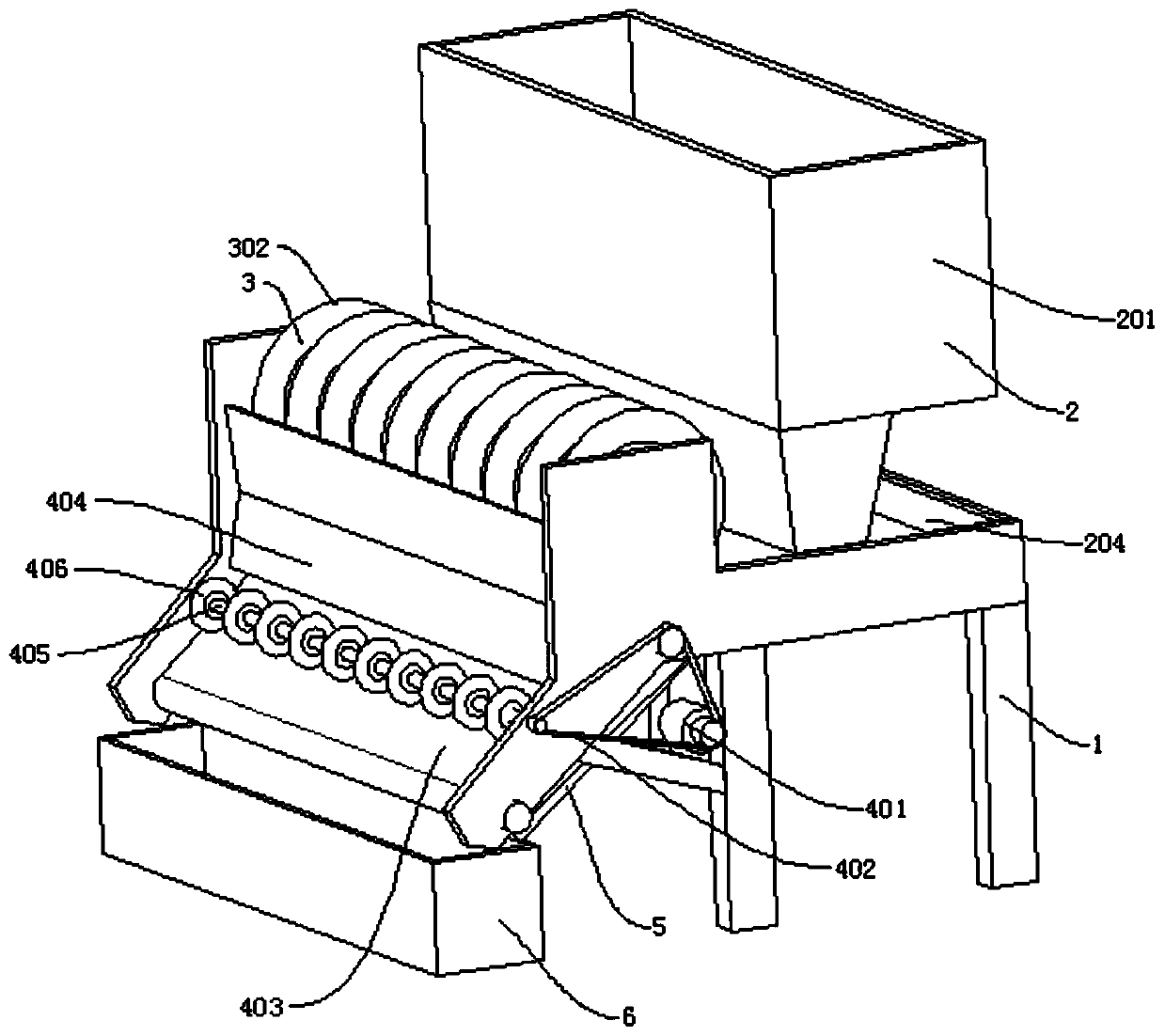

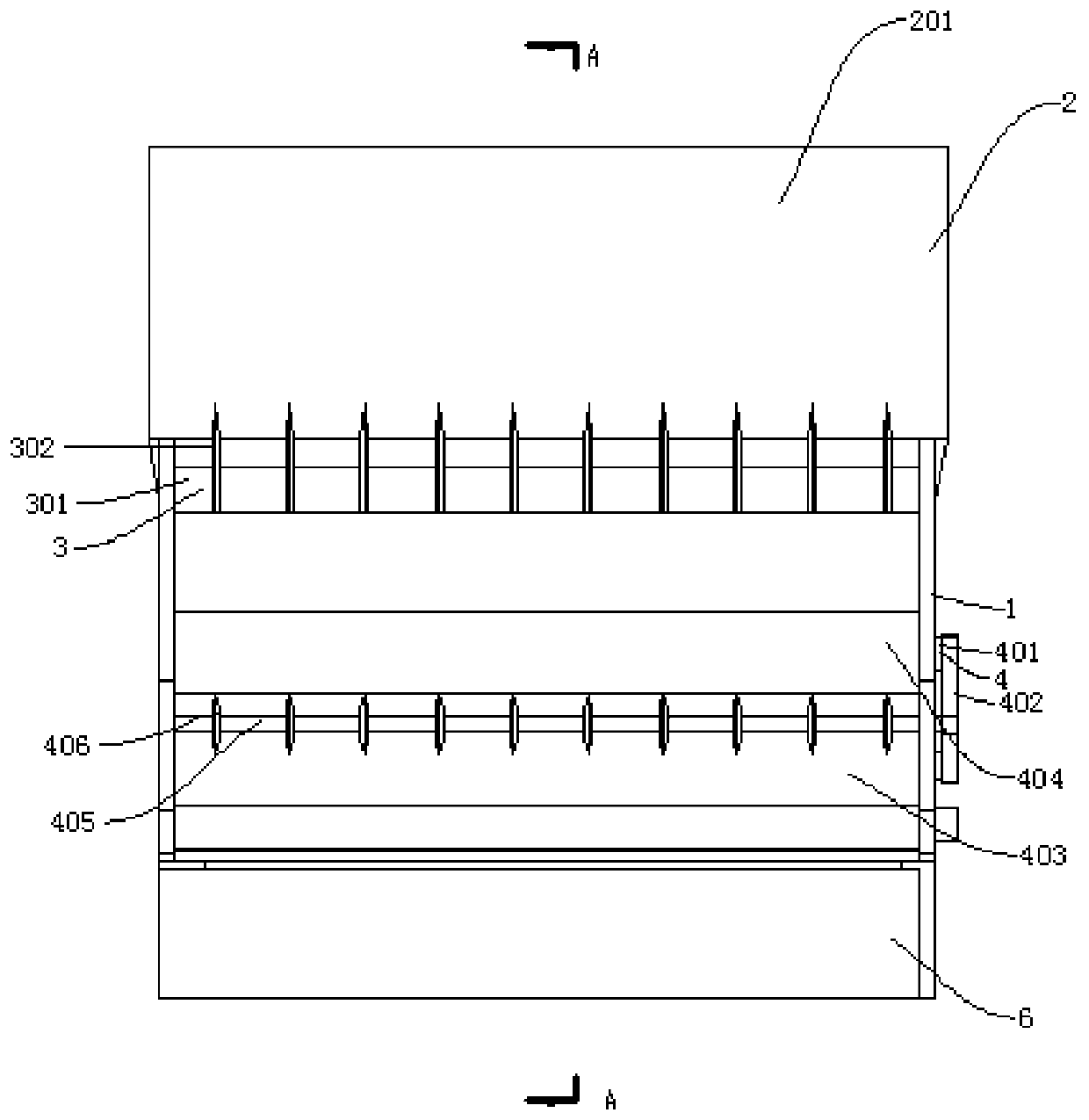

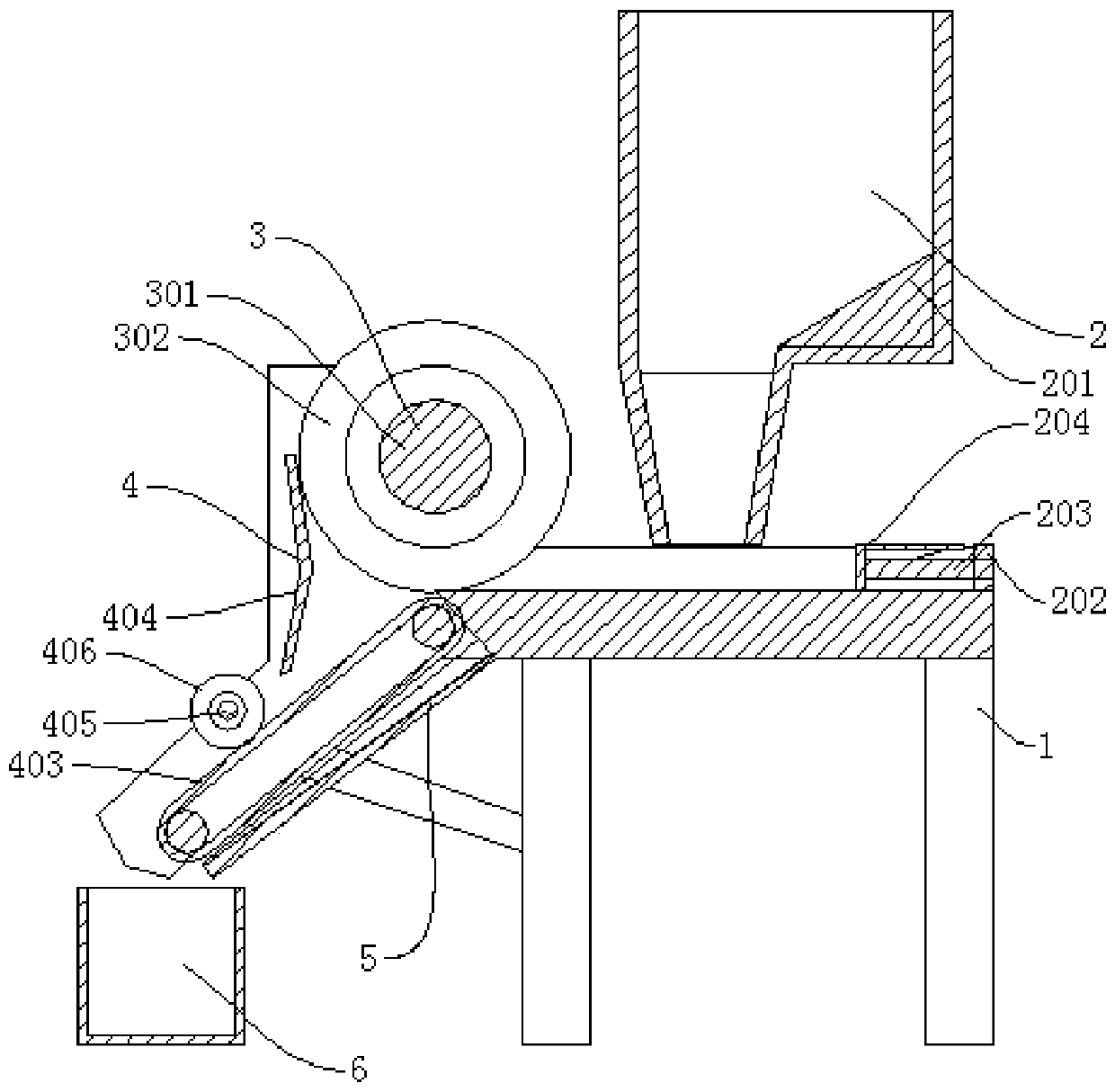

[0026] Such as figure 1 , figure 2 with image 3 As shown, it includes a frame 1, a feeding mechanism 2, a collection box 6, and also includes a first cutting mechanism 3, a second cutting mechanism 4, and a juice retaining plate 5. The top of the frame 1 is provided with a feeding mechanism 2, and the frame 1 For supporting the whole device, a first cutting mechanism 3 is arranged on one side of the feeding mechanism 2, a second cutting mechanism 4 is arranged obliquely below the first cutting mechanism 3, and a juice blocking plate 5 is arranged below the second cutting mechanism 4 to block juice The plate 5 prevents the water between the frame 1 and the conveyor belt 403 from flowing to the ground. A collection box 6 is arranged below the juice retaining plate 5 and the second cutting mechanism 4. The collection box 6 collects the cut vegetables. The second cutting mechanism 4 includes a motor 401 , belt 402, conveyor belt 403, limiting plate 404, turning roller 405, sec...

Embodiment 2

[0029] Such as Figure 4 , Figure 5 with Image 6 As shown, the difference between Embodiment 2 and Embodiment 1 is that the first cutting mechanism 3 includes a connecting plate 31, a cutting rope 32, a connecting ring 33, a tension bolt 34, and a second fixing plate 35, and the connecting plate 31 is connected by screws. Below the frame 1, one end of the cutting rope 32 is fixed above the connecting plate 31, the connecting plate 31 and the connecting ring 33 are used to fix the cutting rope 32, and the other end of the cutting rope 32 is fixed on the connecting ring 33, and the cutting rope 32 cuts the vegetables into A tension bolt 34 is welded above the connecting ring 33. The tension bolt 34 is used to tighten the cutting rope 32. The tension bolt 34 passes through the second fixing plate 35 and is threadedly connected with the second fixing plate 35. The second The fixing plate 35 is used for fixing the tension bolt 34 .

[0030] In the above structure, firstly, by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com