Undercarriage testing plane mounting support assembly process and tool

A technology for installing supports and testing machines, which is applied in the direction of manufacturing tools, workpiece clamping devices, etc., and can solve problems such as low precision and dimensional precision, dependence on the quality of operators, and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

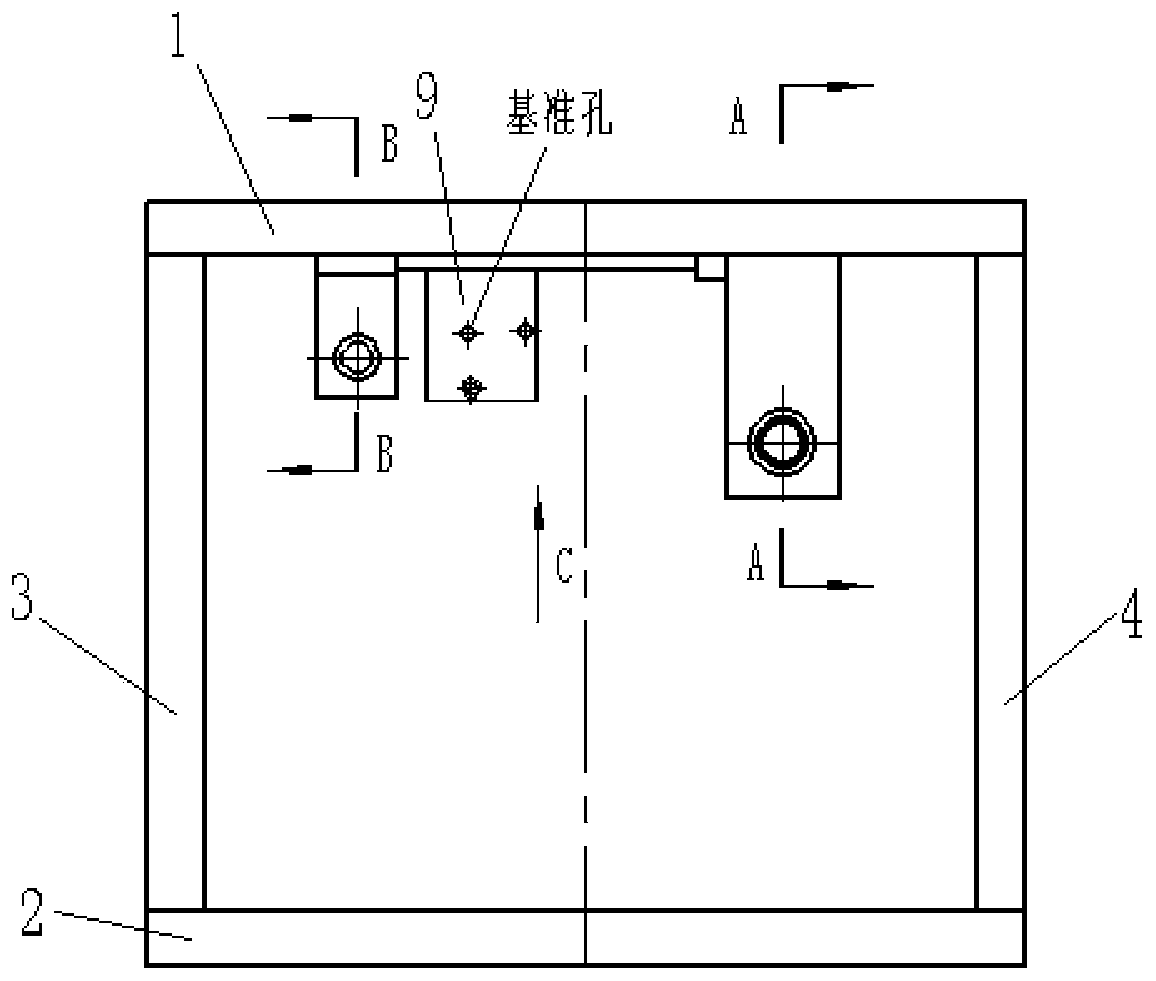

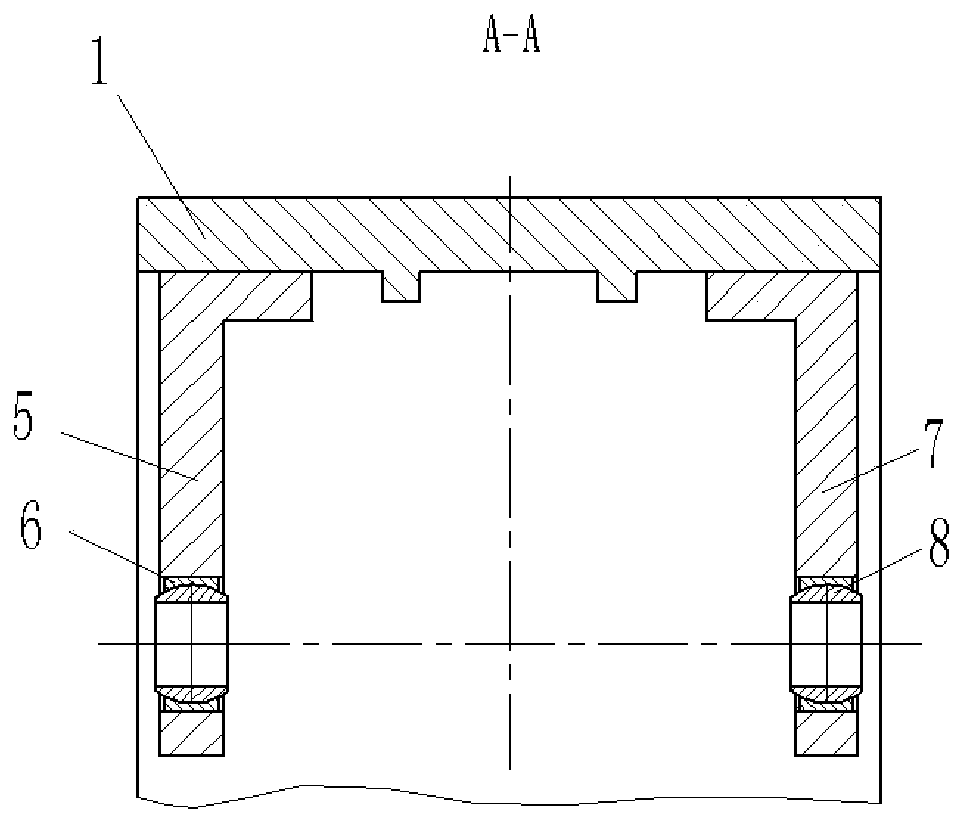

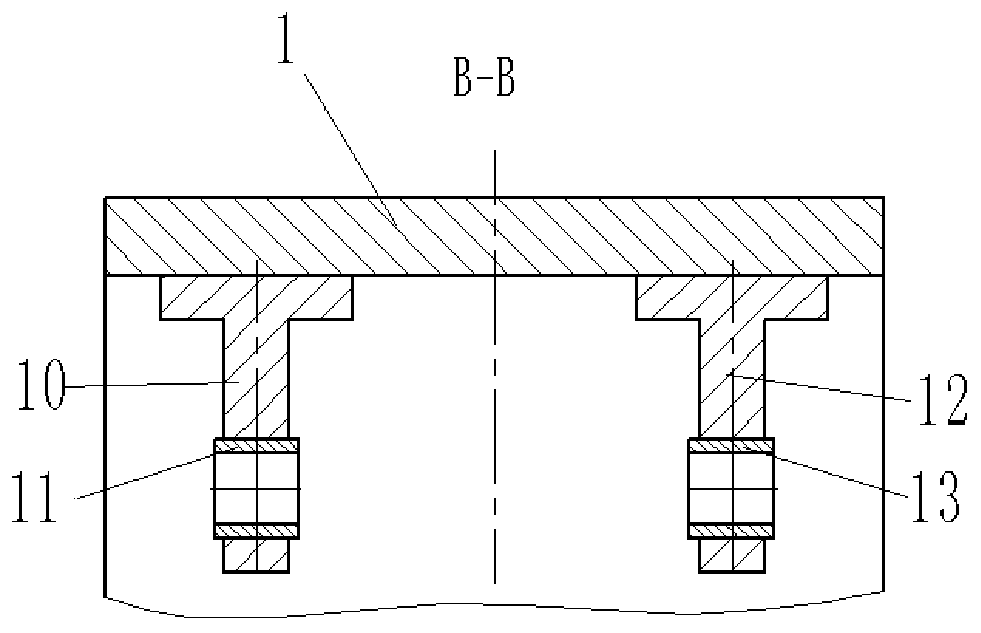

[0063] Such as Figure 1-11 As shown, the present invention provides a kind of landing gear testing machine mounting support tooling, comprises testing machine frame upper beam 1, testing machine frame base 2, test machine frame left column 3, test machine frame left and right columns 4, Main slewing support A5, joint bearing A6, main slewing support B7, joint bearing B8, landing gear lock support 9, retractable actuator support A10, copper sleeve A11, retractable actuator support B12, copper Sleeve B13, main slewing support installation mandrel 14, main slewing support installation tool 15, retractable actuating cylinder support installation mandrel 16, retractable actuating cylinder support installation tool A17, retractable actuating cylinder support Install tooling B18, reference block A19, reference bar A20, reference bar B21, reference block B22 and other components.

[0064] The lower surface of the test machine frame base 2 is fixed on the concrete foundation, the lef...

Embodiment 2

[0072] On the basis of embodiment 1, the present invention also provides a kind of landing gear testing machine mounting support assembly process that adopts the landing gear testing machine mounting support tooling to install the landing gear testing machine mounting support, comprising the following steps:

[0073] S1. Install the joint bearing A6 into a suitable position in the through-cylindrical through hole on the first rectangular vertical plate of the main slewing support A5 and fix it;

[0074] S2. Install the joint bearing B8 into a suitable position in the through-cylindrical through hole on the first rectangular vertical plate of the main slewing support B7 and fix it;

[0075] S3, put the copper sleeve A11 into the suitable position in the through-cylinder through hole on the second rectangular vertical plate of the retractable actuator support A10 and fix it;

[0076] S4, put the copper sleeve B13 into the appropriate position in the through-cylinder through hole o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com