Receiving Ultrasonic Transducer Based on Helmholtz Resonant Cavity and Reduced Air Damping

An ultrasonic transducer and air damping technology, which is applied in the direction of fluid using vibration, can solve the problems of cavity resonance frequency increase and quality factor Q decrease, so as to reduce air damping, prevent crosstalk, increase acoustic-electric conversion efficiency and The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

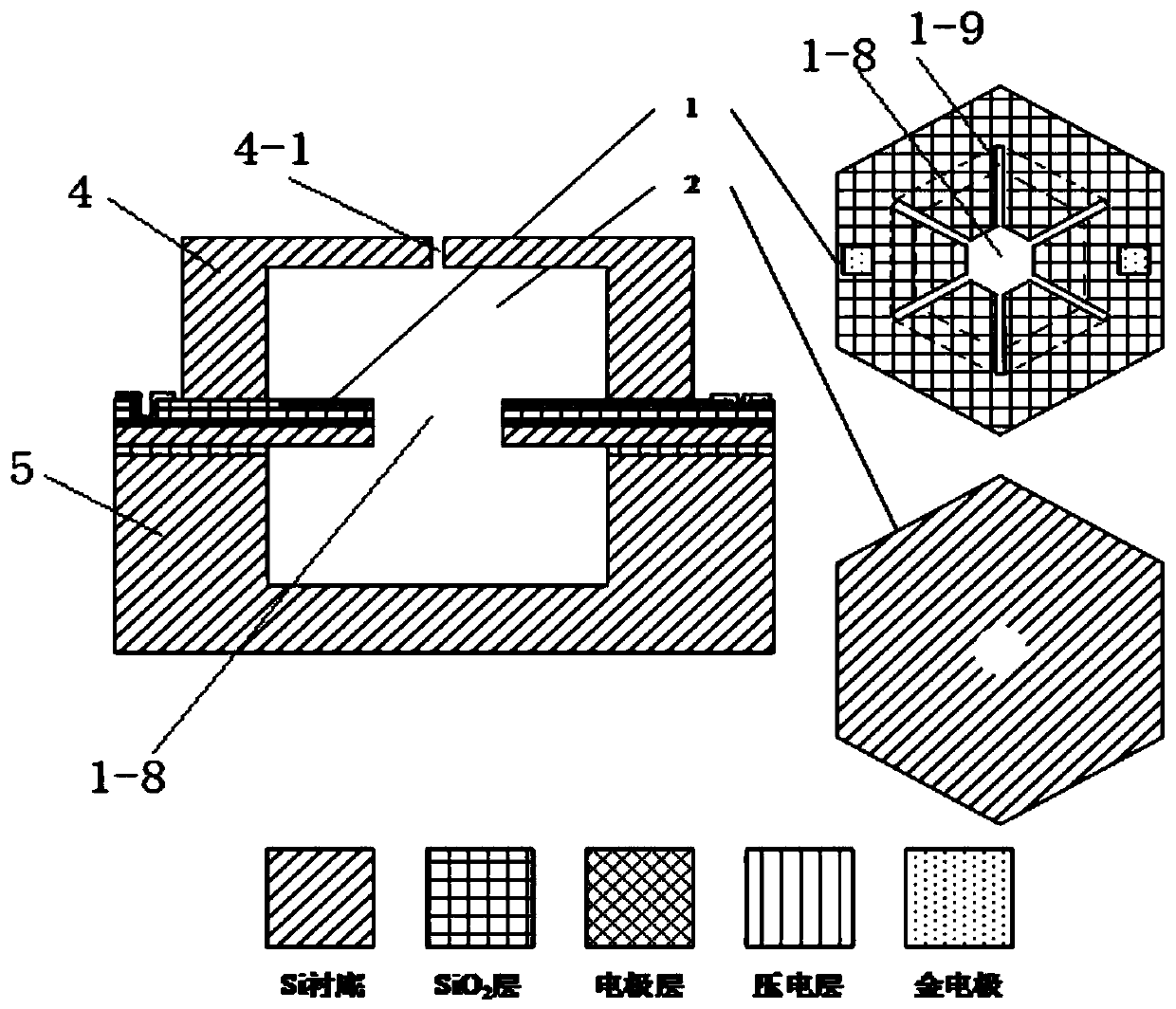

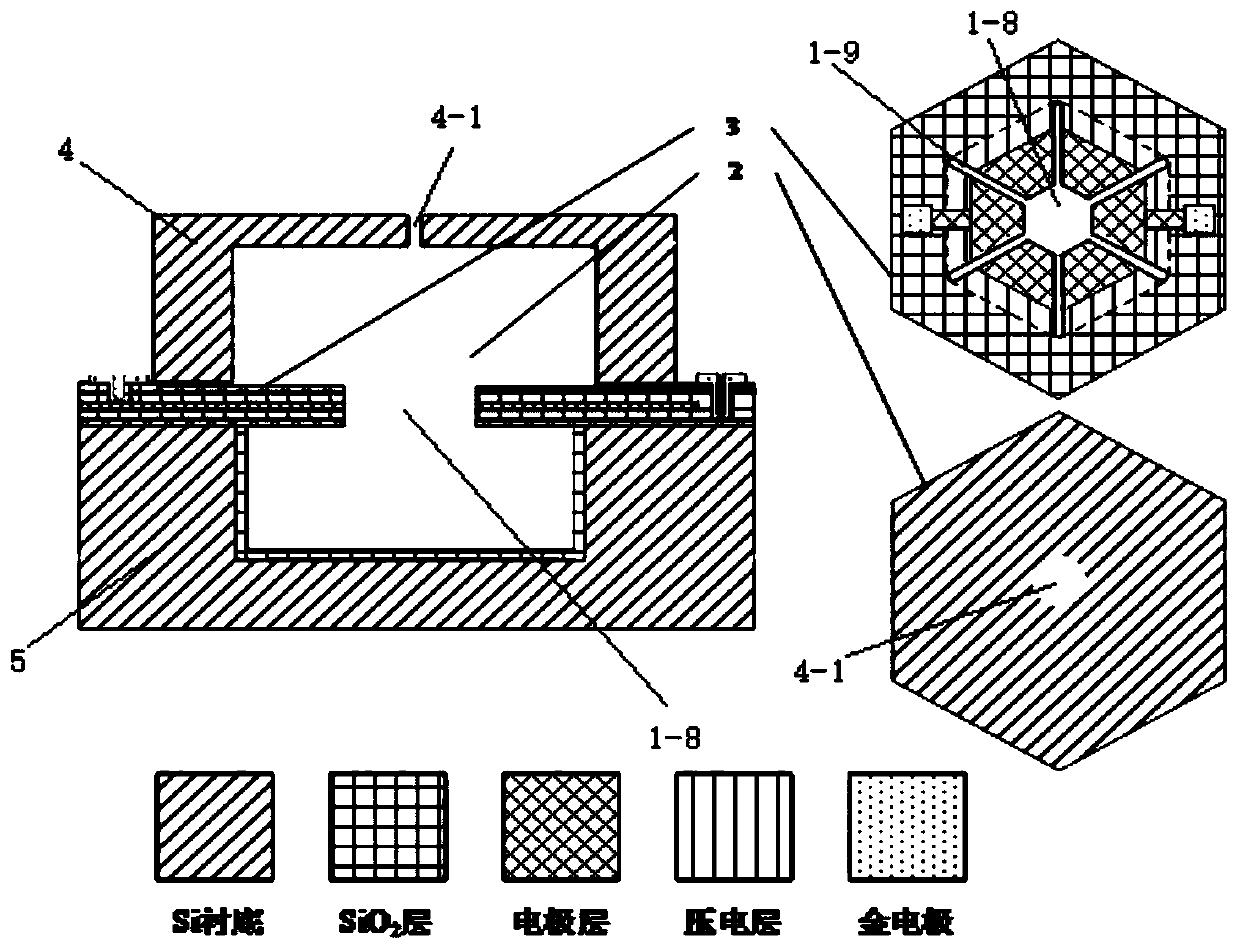

[0031] like figure 1 , 2 , 3, 4, a receiving ultrasonic transducer based on a Helmholtz resonant cavity and reducing air damping, comprising a Helmholtz resonant cavity 2 at the upper part and a MEMS piezoelectric ultrasonic transducer at the lower part, the Helmholtz resonant cavity 2 and The MEMS piezoelectric ultrasonic transducers are bonded by bonding. The MEMS piezoelectric ultrasonic transducer is composed of a piezoelectric laminated structure on the top and a silicon substrate 5 with a cavity on the bottom.

[0032] The Helmholtz resonant cavity 2 is formed by bonding a silicon structure 4 with a cavity with an upper opening 4-1 above the piezoelectric stack structure. The piezoelectric laminated structure is bonded together to form a Helmholtz resonant cavity 2, and a Helmholtz resonant cavity hole is formed in the upper opening 4-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com