Hydraulic reversing valve and hydraulic reversing device

A technology of hydraulic reversing valve and valve sleeve, which is applied to valve device, fluid pressure actuating device, valve operation/release device, etc. High frequency commutation requirements and other issues to achieve the effect of high commutation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

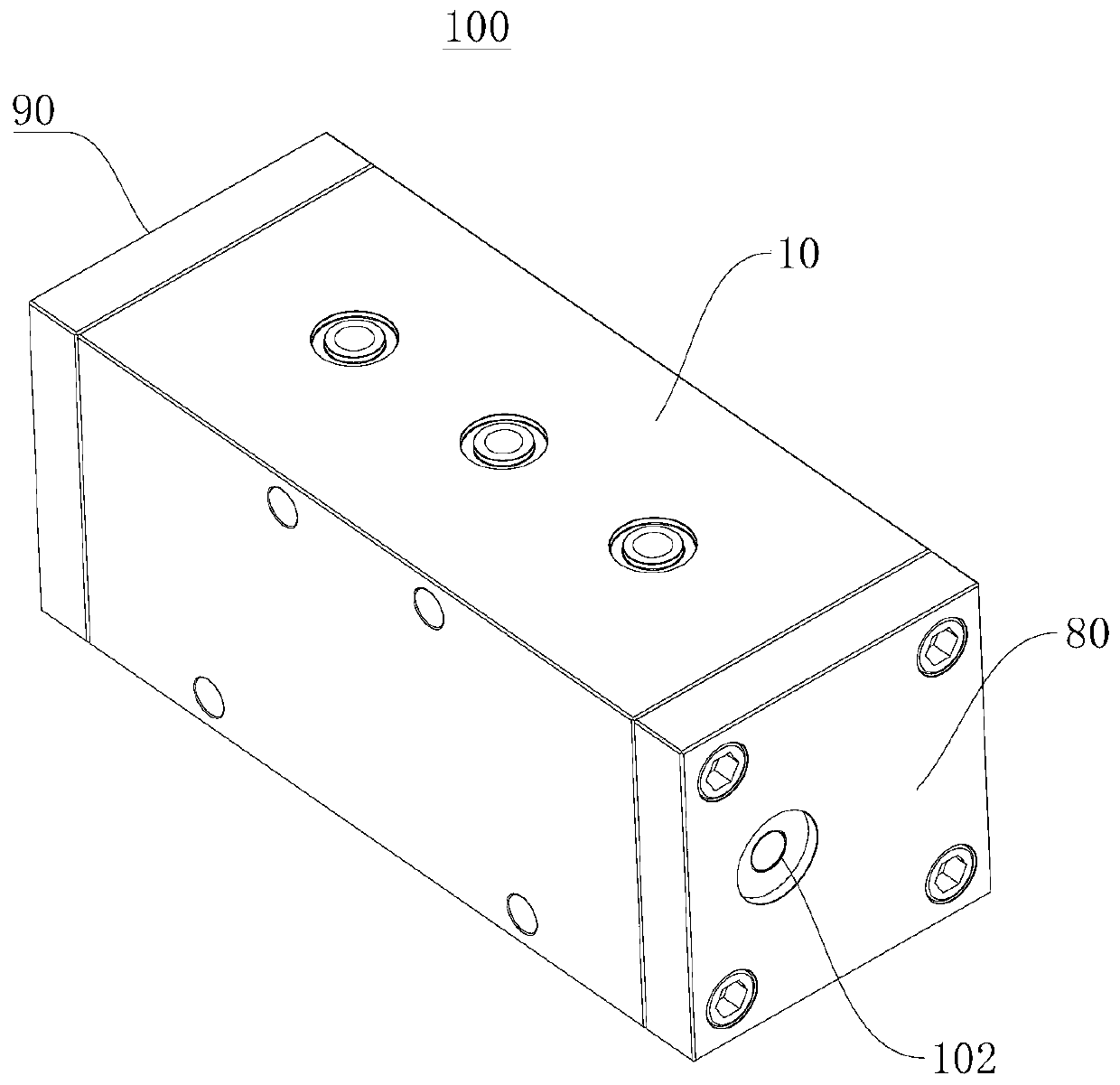

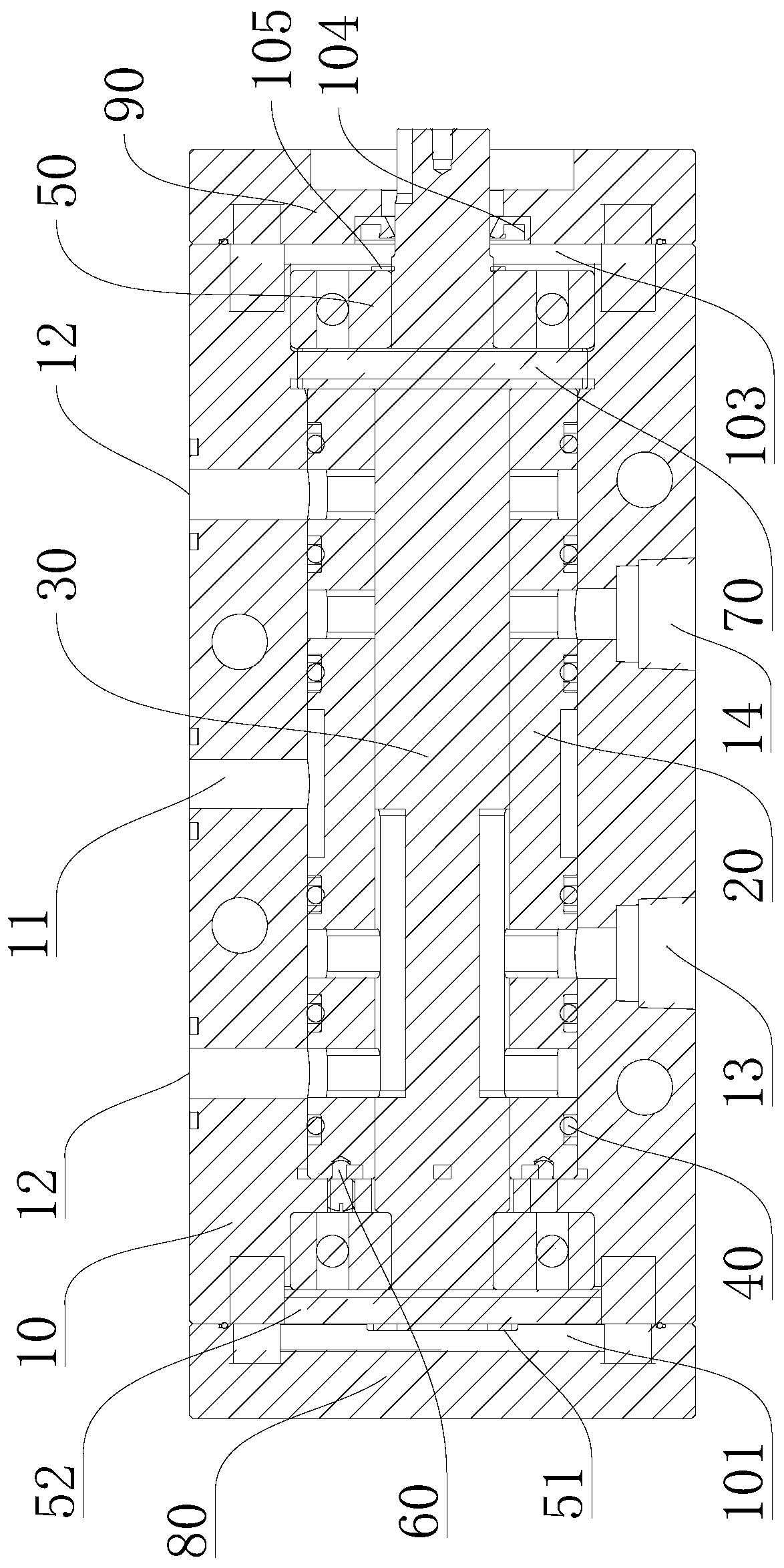

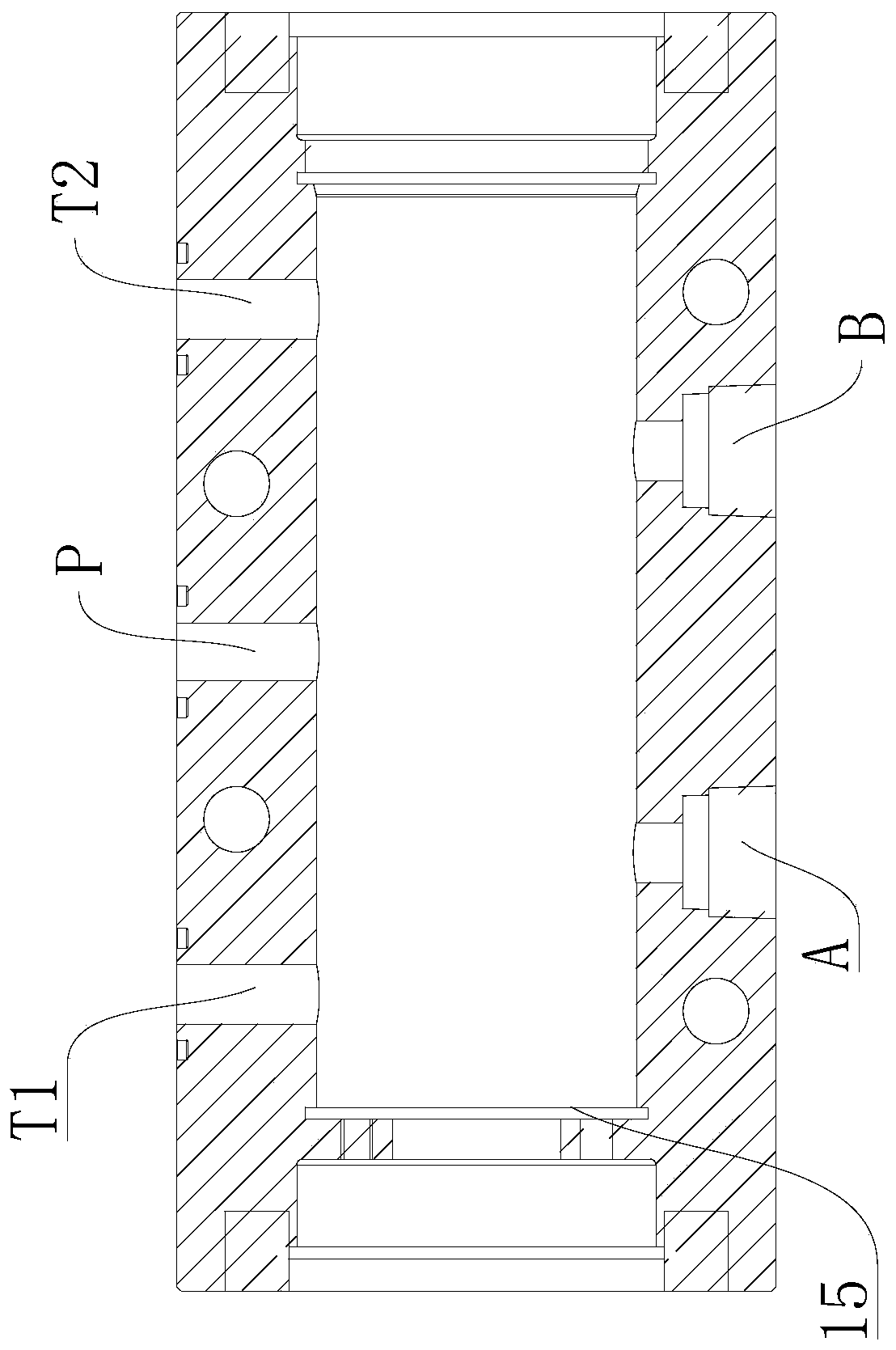

[0052] Please refer to Figure 1 to Figure 7 , this embodiment provides a hydraulic reversing valve 100, including: a valve body 10, a valve sleeve 20 and a valve core 30;

[0053] The interior of the valve body 10 has a first installation chamber, and the valve body 10 also includes a pressure oil port 11 communicating with the first installation chamber, an oil return port 12, a first working port 13 and a second working port 14, and a valve sleeve 20 set in the first installation chamber;

[0054] There is a second installation chamber inside the valve sleeve 20, and a plurality of oil grooves are opened in the circumferential direction of the valve sleeve 20, and the plurality of oil grooves are all provided with liquid passage holes 25 communicating with the second installation chamber. The pressure oil channel 21 communicated with the pressure oil port 11, the switching oil channel 22 communicated with the working port, and the oil return channel 23 communicated with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com