Neutral point control device for plunger pump

A technology of control device and neutral point, which is applied in pump control, liquid variable displacement machinery, machine/engine, etc. It can solve the problems of inconvenient debugging, inaccurate midpoint of plunger pump, and unguaranteed accuracy, etc., and achieve operation Stability, reasonable structure, and the effect of ensuring the accuracy of equipment use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

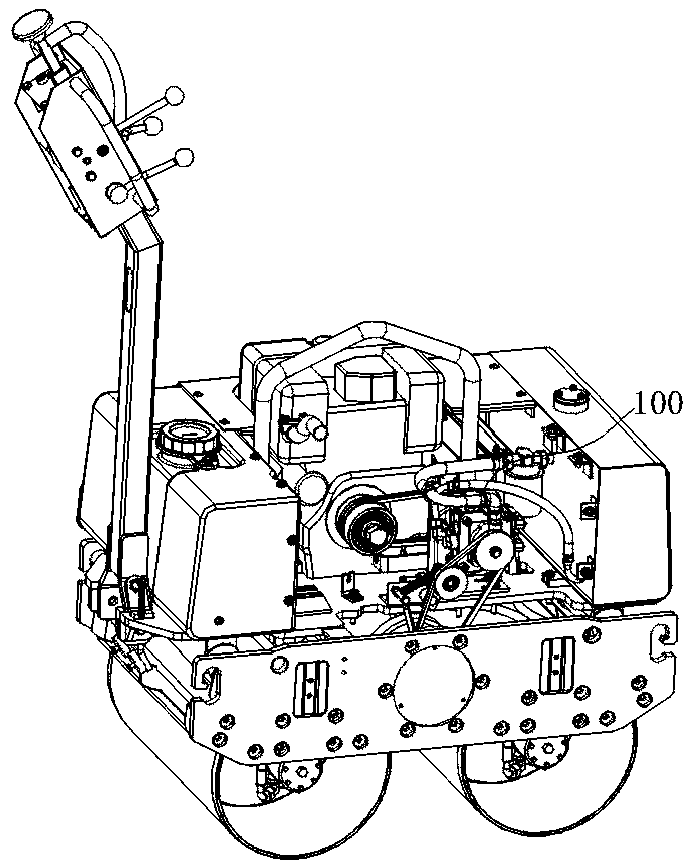

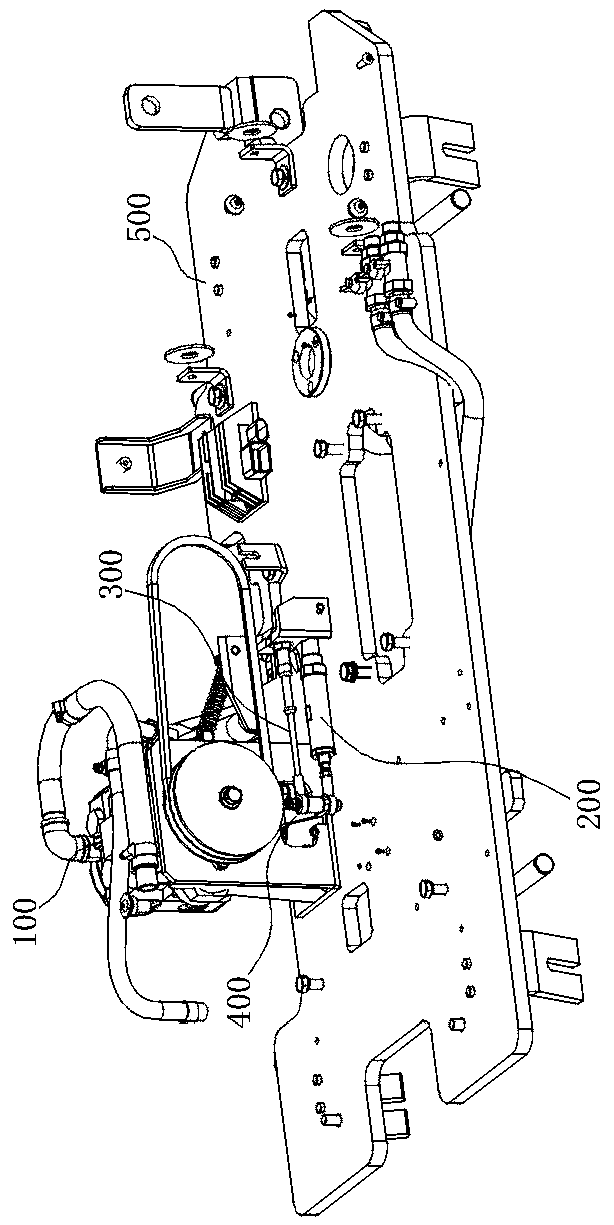

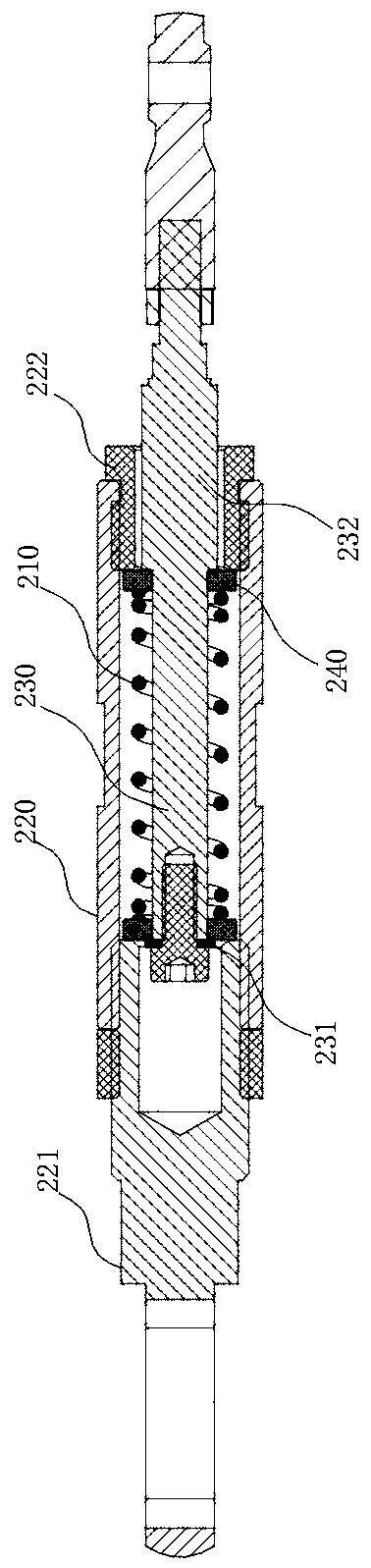

[0035] refer to Figure 1-3, in the embodiment of the present invention, a plunger pump neutral point control device is proposed. The neutral point control device is installed on the tray 500 and connected with the plunger pump 100 on the tray 500. The plunger pump 100 is equipped with a rotating shaft. The rotating shaft is connected to the adjustment mechanism, and the adjusting mechanism adjusts the oil circuit movement direction of the plunger pump 100 by driving the rotating shaft to rotate. When the rotating shaft rotates to the neutral position, the plunger pump 100 is in an idle state, including the energy storage mechanism 200, which is connected to the rotating shaft When the adjusting mechanism adjusts the rotation of the rotating shaft, the rotating shaft drives the energy storage mechanism 200 to run and stores potential energy in the energy storage mechanism.

[0036] Through the setting of the energy storage mechanism 200, when the adjustment mechanism adjusts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com