Construction method of prefabricated steel cage for rapid tunnel lining

A construction method and reinforcement cage technology, which are applied in tunnel lining, shaft lining, tunnels, etc., can solve the problems of difficulty in dissipating dust and smoke, inefficient binding and welding of reinforcement cages, and endangering the health of on-site workers. Improve efficiency, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

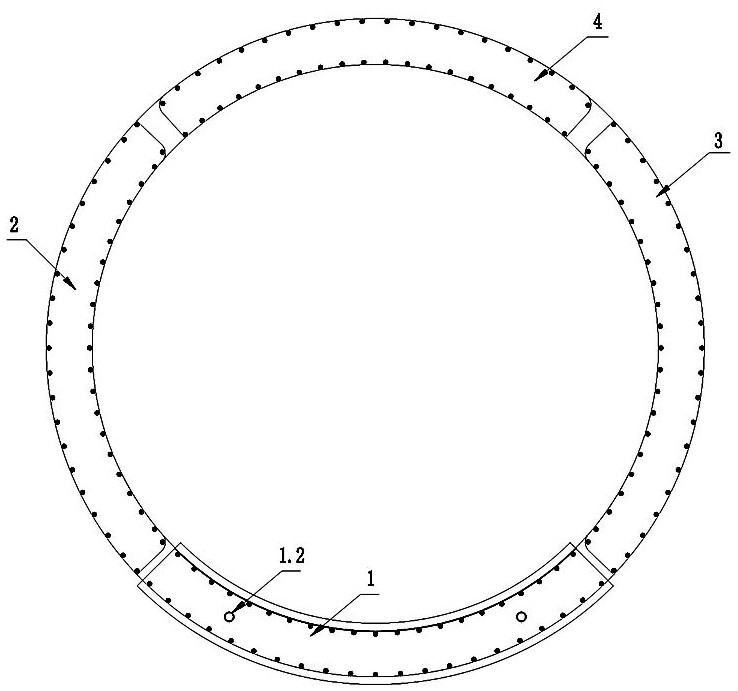

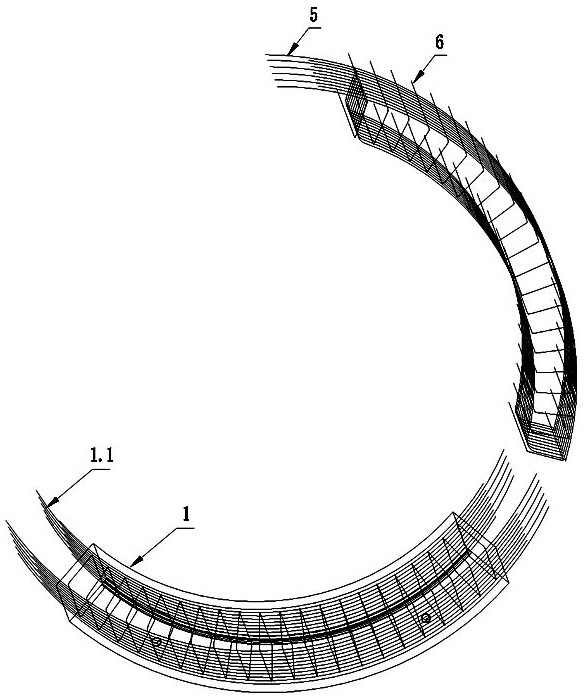

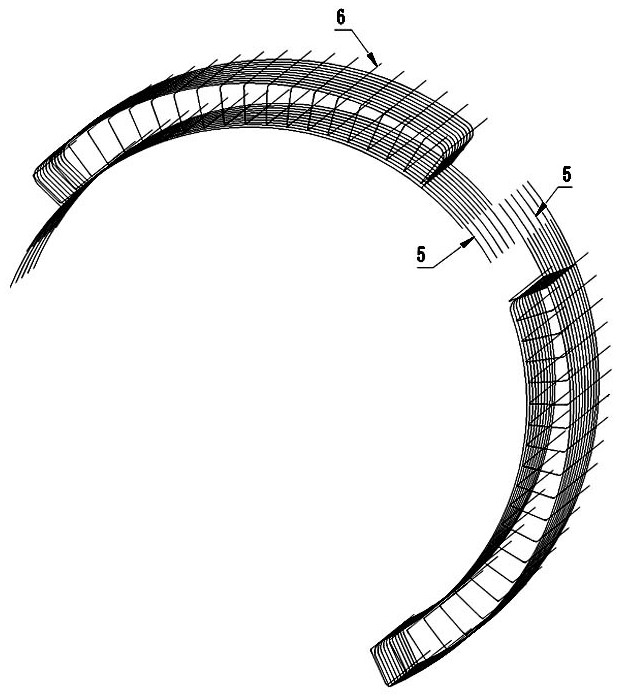

[0024] like Figure 1~Figure 3 As shown, the construction method of the assembled steel cage for tunnel rapid lining according to the present invention is carried out according to the following steps:

[0025] Step 1. According to the diameter of the tunnel excavation, the tunnel lining is designed to be a tunnel lining unit of 3 meters along the tunnel axis, so as to facilitate transportation and installation; each tunnel lining unit is designed as a bottom block divided along the ring direction , the left block, the right block and the top block are connected to form a ring structure;

[0026] Step 2, prefabricate the bottom block 1 outside the tunnel, bind the reinforcement cage 2 of the left block, the reinforcement cage 3 of the right block and the reinforcement cage 4 of the top block; The ends respectively extend out of their circumferential joint surfaces, and are used to overlap with the circumferentially stressed steel bars of the connected left and right side block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com