Clamp and method for polishing plane optical part

A technology of optical parts and fixtures, applied in optical surface grinders, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of prolonging processing time, chipping, and long time, and achieve improved product qualification rate, convenient disassembly, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

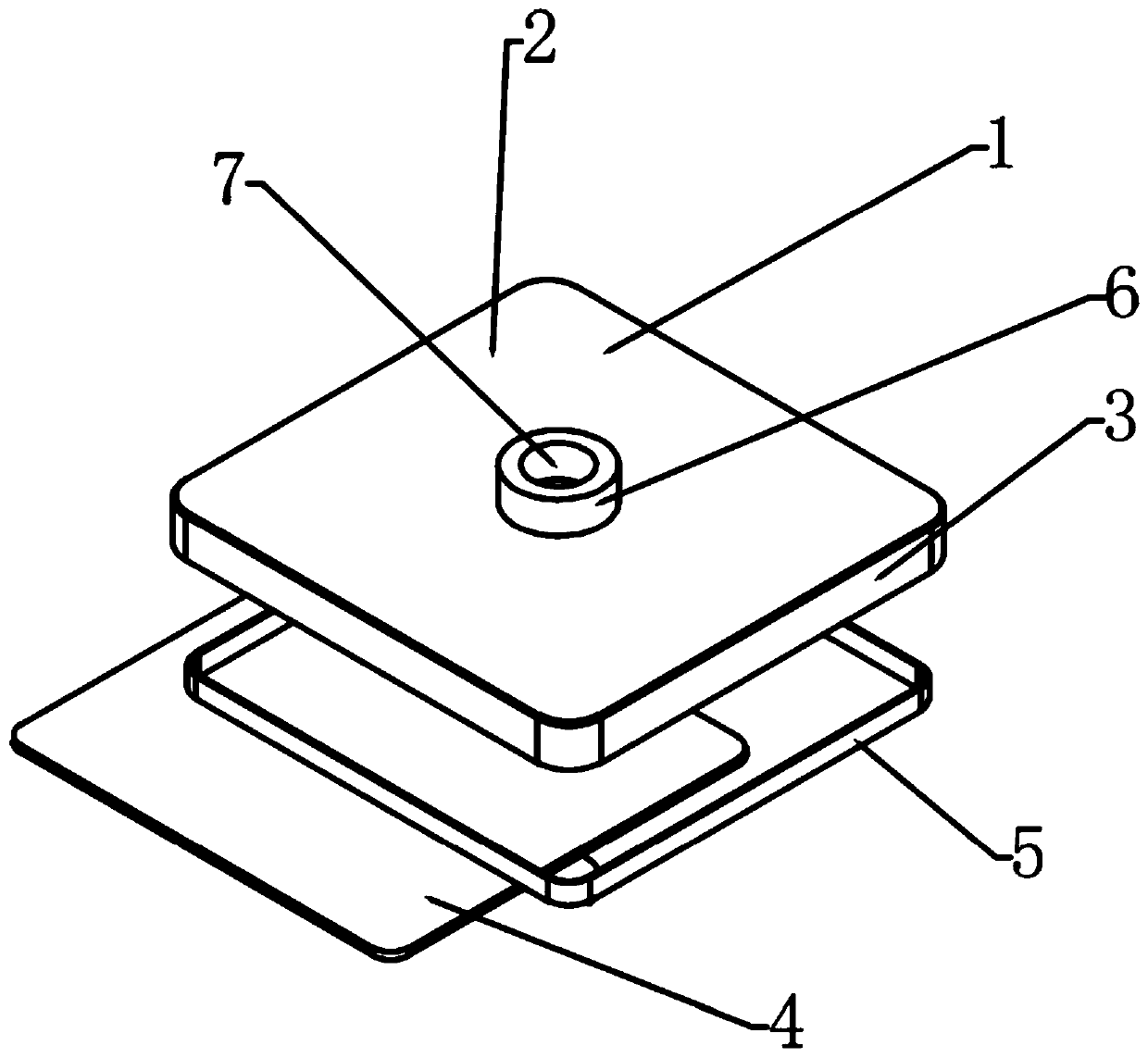

[0040] A kind of fixture that is used for the polishing of planar optical part as the embodiment of the present invention, as figure 1 , figure 2As shown, the clamp 1 is a clamp with a rectangular groove shape, the clamp includes a base 2 and a rib 3, the base 2 is a rectangular plate, and a rib 3 is fixed around the base, and the rib 3 and the The base 2 is vertical, the rib 3 and the base 2 form a groove 8, the depth of the groove 8 is smaller than the thickness of the planar optical part, and the opposite side of the groove surface of the base is provided with a grinding and polishing machine The screw thread 6 that the main shaft cooperates and the stylus hole 7 that cooperates with the stylus of grinding and polishing machine; The bottom surface protection pad 4 is arranged in the groove of described clamp, and the shape of the bottom surface protection pad 4 is consistent with the shape of the bottom surface of the groove, The material of the bottom protection pad is d...

Embodiment 2

[0053] A kind of fixture that is used for the polishing of planar optical part as the embodiment of the present invention, as image 3 As shown, the only difference between this embodiment and Embodiment 1 is: the bottom surface of the groove is provided with several vertical and horizontal slots, the slots are parallel to the ribs, and the two ends of the slots extend to the Said edge, the clamp also includes an insert that fits with the slit, the insert is a sheet, and the height of the insert when it is inserted on the slit is the same as the height of the edge Consistent, the bottom surface of the groove is provided with 6 longitudinal slits 15, the bottom surface of the groove is provided with 6 transverse slits 16, the two ends of the longitudinal slits extend to the rib, and the transverse slits The two ends of each extend to the rib, the longitudinal slits are perpendicular to the transverse slits, the longitudinal slits are arranged at intervals from the ribs, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com