Ultrafiltration device for improving uniformity of water distribution at large flow rate

A technology of uniform water distribution and large flow, applied in ultrafiltration, general water supply saving, seawater treatment and other directions, can solve the problems of unreasonable layout of ultrafiltration membrane elements, affecting the service life of membrane elements, and large flow deviation of membrane elements, etc. To achieve the effect of improving the uniformity of water distribution, improving the service life and reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

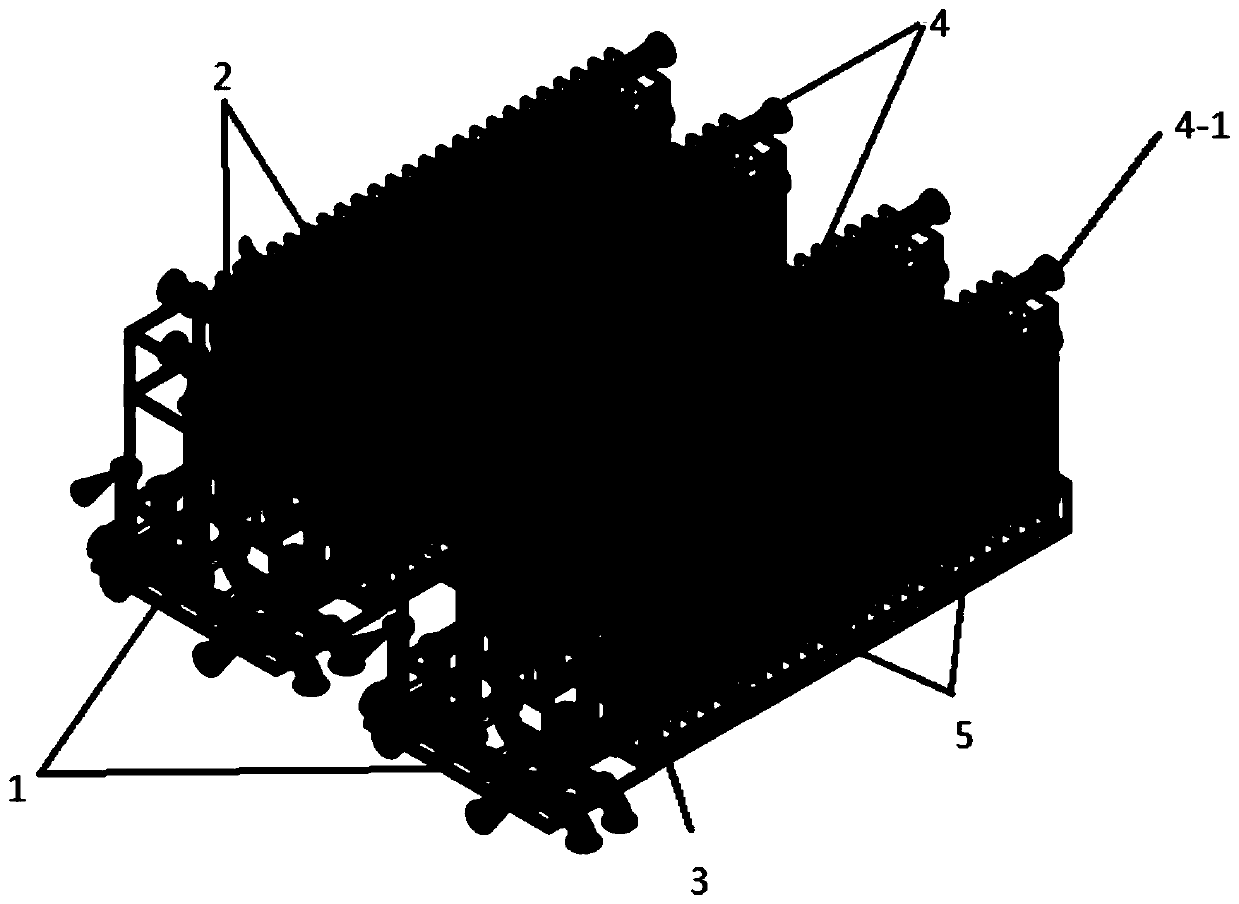

[0014] Specific implementation mode one: combine figure 1 Describe this embodiment, the ultrafiltration device described in this embodiment to improve the uniformity of water distribution at large flow rates, including connecting pipes 3, a plurality of support frames 1 and a plurality of ultrafiltration water inlet and outlet pipes 2, the one A kind of ultrafiltration device that improves the uniformity of water distribution when the large flow rate also includes a plurality of ultrafiltration membrane modules, a plurality of ultrafiltration membrane modules are arranged side by side, a plurality of ultrafiltration water inlet and outlet pipes 2 are vertically arranged side by side, each ultrafiltration The lower ends of the water inlet and outlet pipes 2 for filtration are installed on a support frame 1 respectively, and the upper ends of each water inlet and outlet pipe for ultrafiltration 2 are connected to the corresponding ultrafiltration membrane modules through connecti...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 To illustrate this embodiment, each group of ultrafiltration membrane modules described in this embodiment includes two water distribution pipelines 4 and several ultrafiltration membrane elements 5,

[0018] The center line of each water distribution pipe 4 along the length direction is perpendicular to the center line of the connecting pipe 3 along the length direction, the two water distribution pipes 4 are arranged side by side and in parallel, and the front end of each water distribution pipe 4 is connected to the The pipes 3 are connected, and the plurality of ultrafiltration membrane elements 5 are all connected to the water distribution pipeline. The plurality of ultrafiltration membrane elements 5 are arranged oppositely in two rows, and the water distribution pipeline 4 is located in the middle of the two rows of ultrafiltration membrane elements 5 .

[0019] The arrangement of multiple ultrafiltration mem...

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 To illustrate this embodiment, several ultrafiltration membrane elements 5 described in this embodiment are arranged at equal intervals along the length direction of the water distribution pipeline 4 .

[0022] Other components and connections are the same as those in the first embodiment.

[0023] Specific implementation mode four: combination figure 1 To illustrate this embodiment, the rear end of each water distribution pipe 4 in this embodiment is provided with an end cover 4-1.

[0024] Other components and connections are the same as those in the third embodiment.

[0025] Specific implementation mode five: combination figure 1 To illustrate this embodiment, the number of ultrafiltration membrane modules described in this embodiment is 2-4. The number of ultrafiltration membrane modules can be selected according to actual application conditions, at least two.

[0026] Other components and connections ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com