Motor rotor device and motor

A technology of motor rotor and rotor core, which is applied in the direction of electromechanical devices, motors, electric components, etc., can solve the problems that the maximum speed of the motor cannot reach a high level, is easy to be damaged, and the robustness of the rotor is deteriorated, so as to reduce the amount of permanent magnets, The effect of reducing dosage and reducing tensile stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

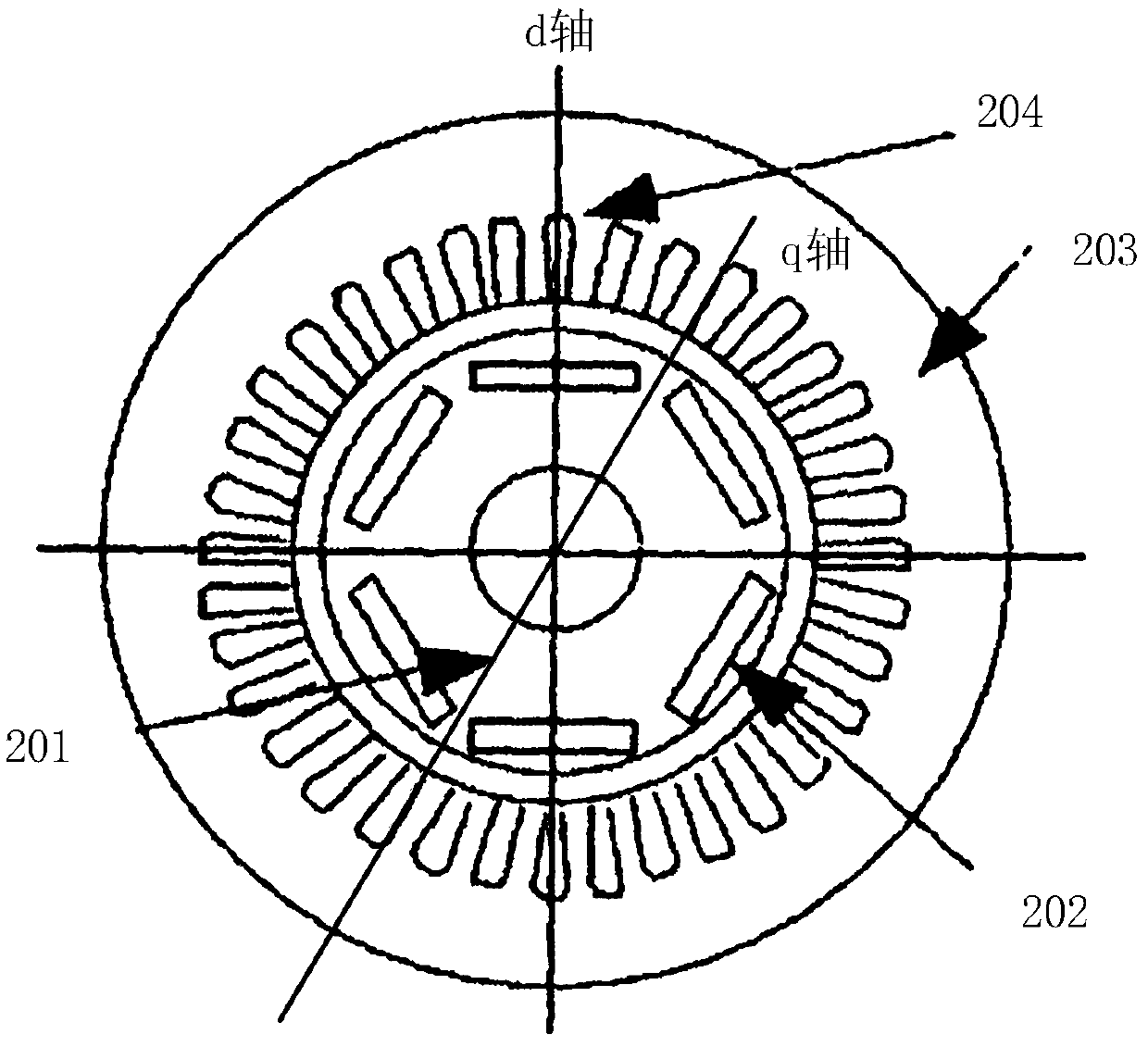

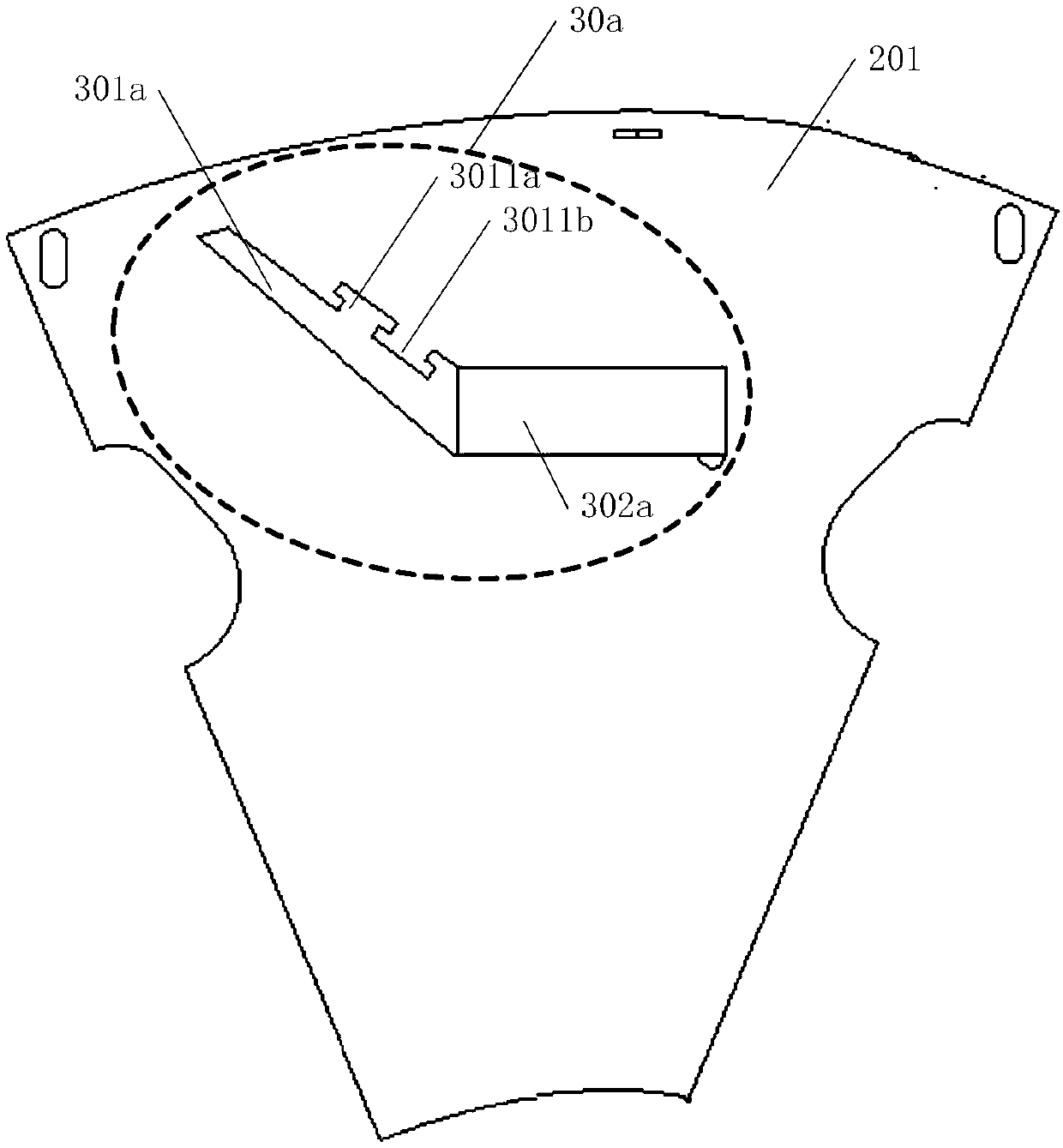

[0042] The present application provides a motor rotor device, which can effectively absorb the centrifugal force generated by the rotor due to high-speed rotation and disperse the effect of the centrifugal force on the magnetic bridge by engaging the adhesive element with the first sub-air groove on the rotor core to form a bearing surface The force ensures the robustness of the rotor at high speed rotation, and can increase the maximum speed of the motor to a certain extent.

[0043] The increasingly popular electric vehicles satisfy the modern society's life concept of energy saving and environmental protection, so improving the performance of electric vehicles has become the main problem to be solved. figure 1It is a simplified schematic diagram of a motor-driven vehicle, in which the permanent magnet synchronous motor can be used as the main drive motor of an electric vehicle to provide a power source for the electric vehicle to generate driving torque. The motor is driven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com