Lithium battery electrode surface defect detection method based on background standardization and centralized compensation algorithm

An electrode surface, centralized compensation technology, applied in computing, image data processing, instruments, etc., can solve problems such as time-consuming calculation, sensitivity to noise, and poor detection effect of detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

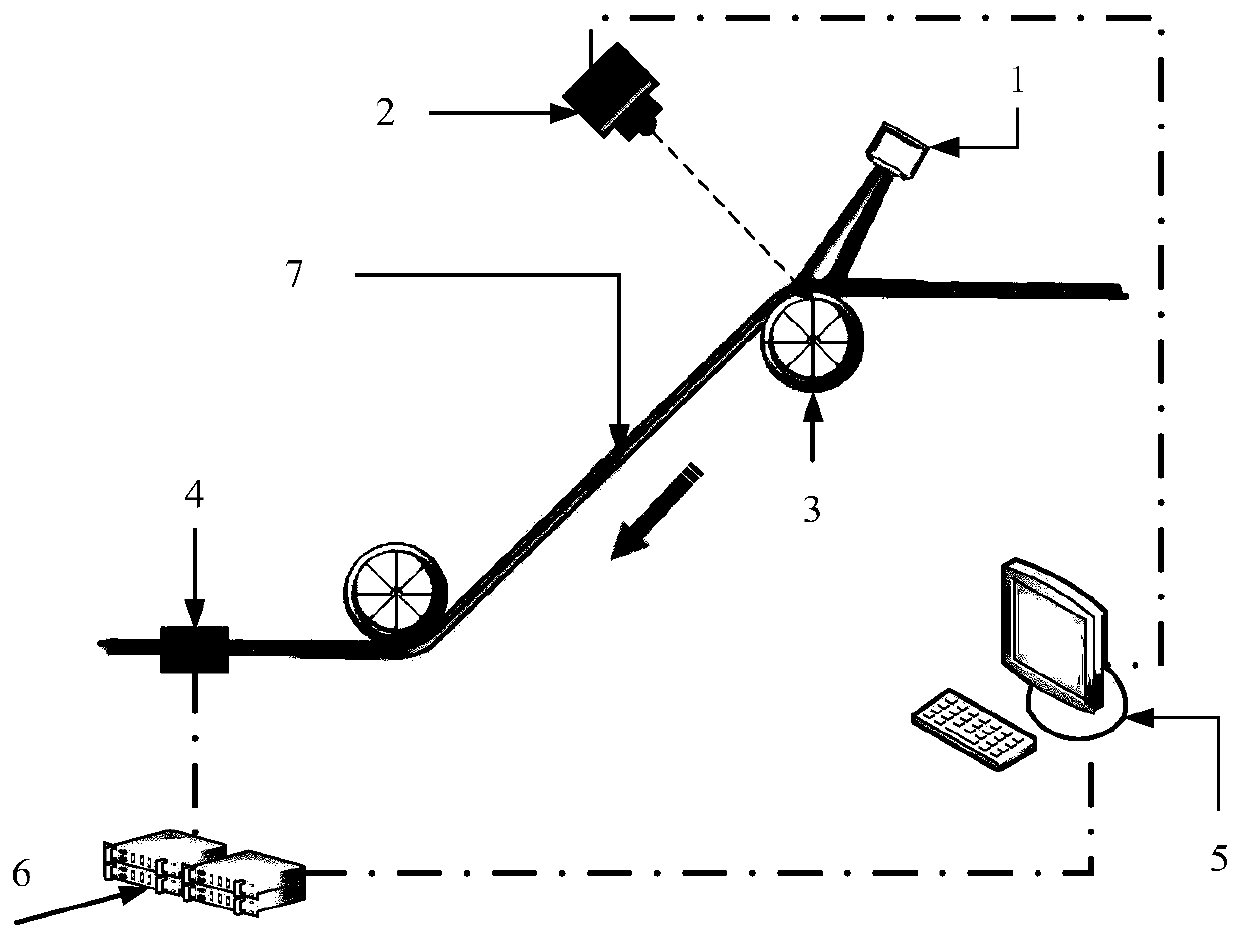

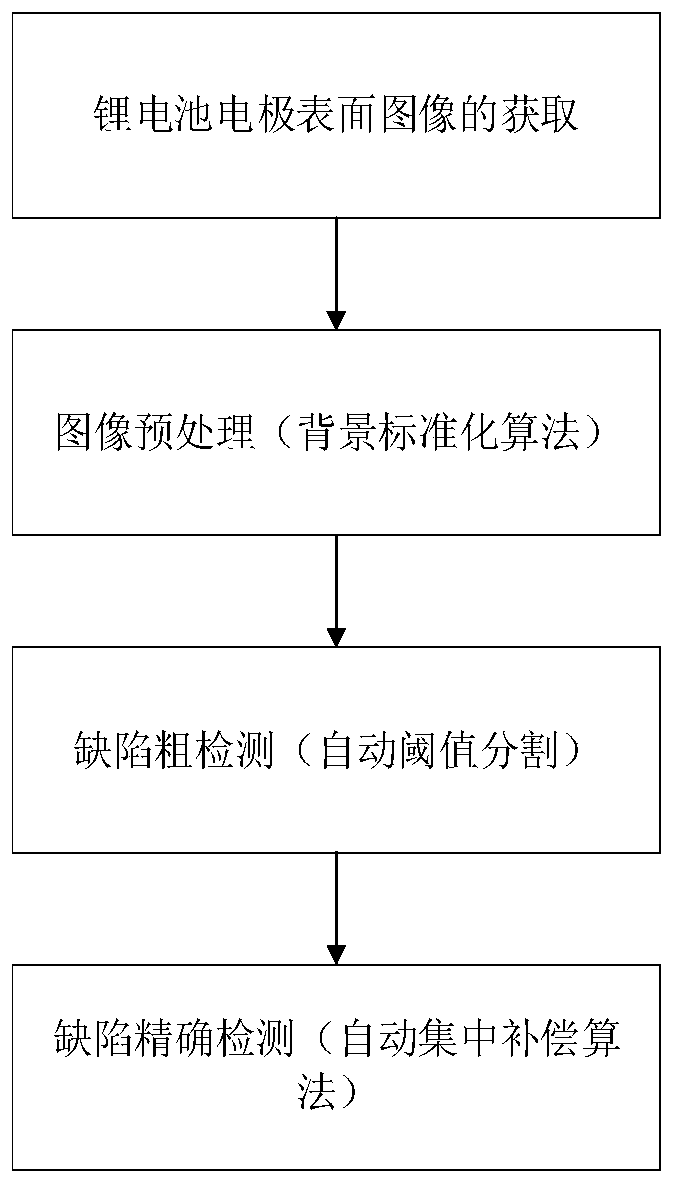

[0087] This embodiment provides a lithium battery electrode surface defect detection method based on background standardization and centralized compensation algorithm, the defect detection method consists of figure 1 The automatic optical inspection system shown is realized, and the automatic optical inspection system is composed of lighting equipment 1 , linear scanning camera 2 , conveying device 3 , labeling machine 4 , industrial computer 5 and programmable logic controller (PLC) 6 . The defect detection process of the automatic optical inspection system is as follows: the lithium battery electrodes are conveyed on the conveying device 3, and at the same time, the linear scan camera 2 captures the surface image of the lithium battery electrodes conveyed on the conveying device 3 under the stable light conditions provided by the lighting equipment 1 , and transmit the image data to the industrial computer 5 for algorithm analysis. When the surface defect of the lithium batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com