Knock-resistant testing device and experimental method thereof

A test device and anti-knock technology, applied in the direction of measurement device, vibration test, impact test, etc., can solve the problems of extensive design and few test items, and achieve the effect of simple operation and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

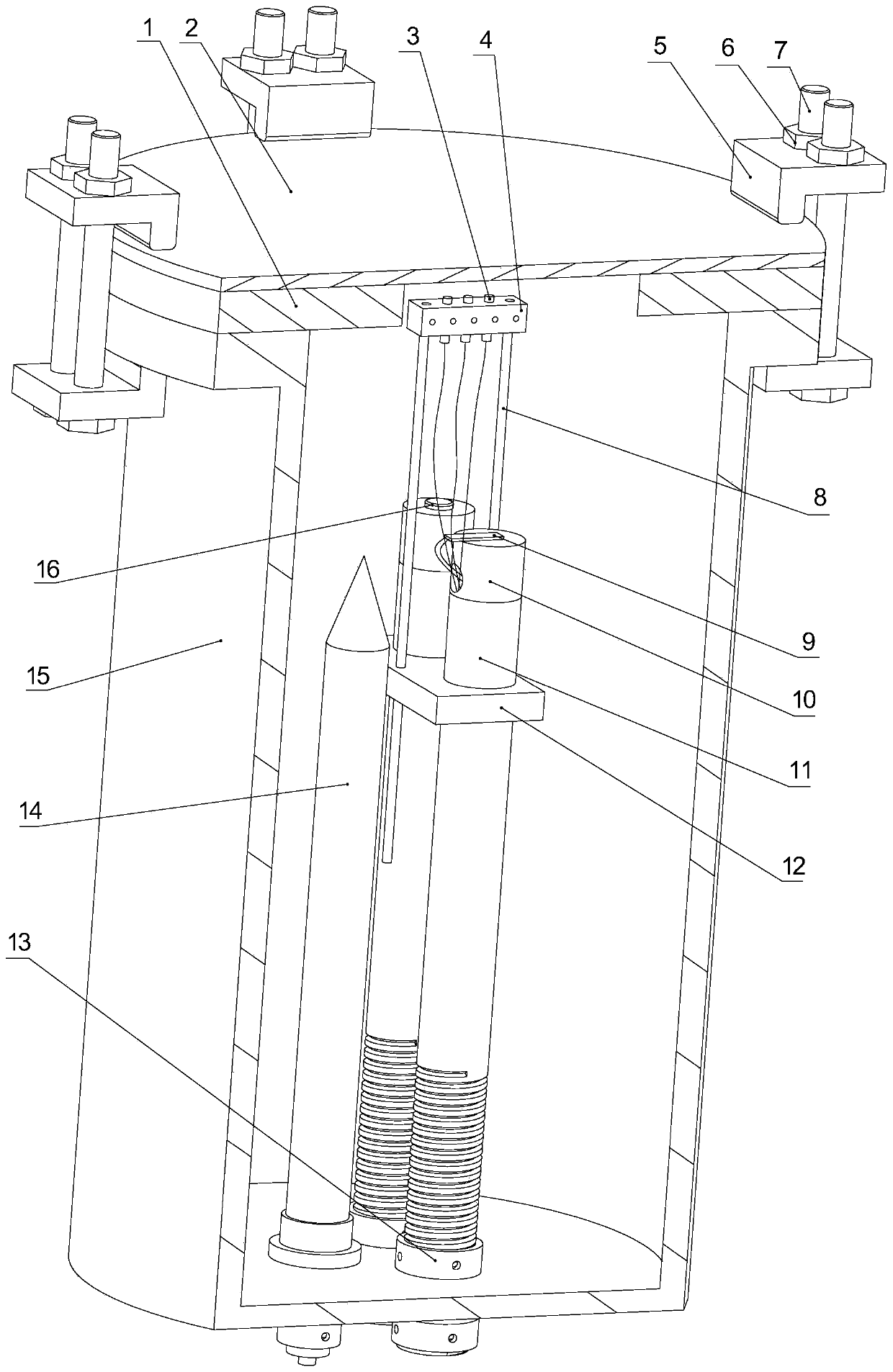

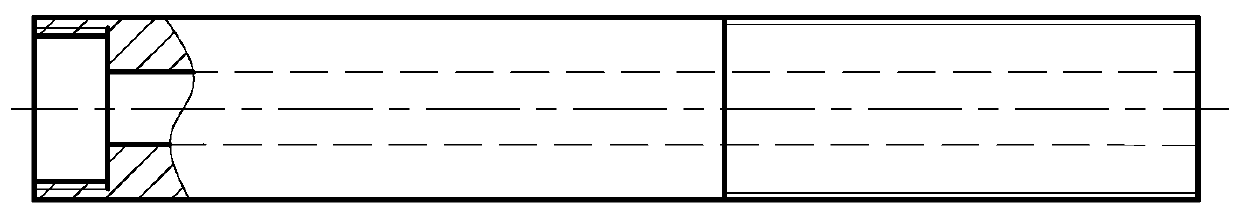

[0020] Such as Figure 1-Figure 2 As shown, the present invention provides a kind of anti-knock test device, comprises simulated cabin, cabin end cover and test system, and its main components are: cabin end cover 1, sample 2, PDV probe 3, PDV base 4, fixture 5 , Nut 6, bolt 7, guide column 8, pressure sensor 9, sensor base 10, sensor bracket 11, PDV bracket 12, special nut 13, PCB sensor 14, simulation cabin 15.

[0021] The bottom end of the simulation cabin 15 is prefabricated with a sensor bracket 11 installation hole, and the sensor bracket 11 is fixed on the simulation cabin 15 by the first nut 13. The lower end of the sensor bracket 11 is prefabricated with threads, and the sensor bracket can be adjusted arbitrarily by adjusting the position of the first nut 13 11 and the relative position of the simulation cabin 15, the sensor bracket 11 adopts a hollow design, so that the test cable can be connected to the simulation cabin 15. The sensor base 10 is screwed to the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com