1000T pure-electric three-head tractor

A tractor, pure electric technology, applied in the field of 1000T pure electric three-head tractor, can solve the problems of chain self-heavy, high running noise, lower yield of aluminum profiles, etc., and achieve fast traction speed, low running noise, and finished product rate. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

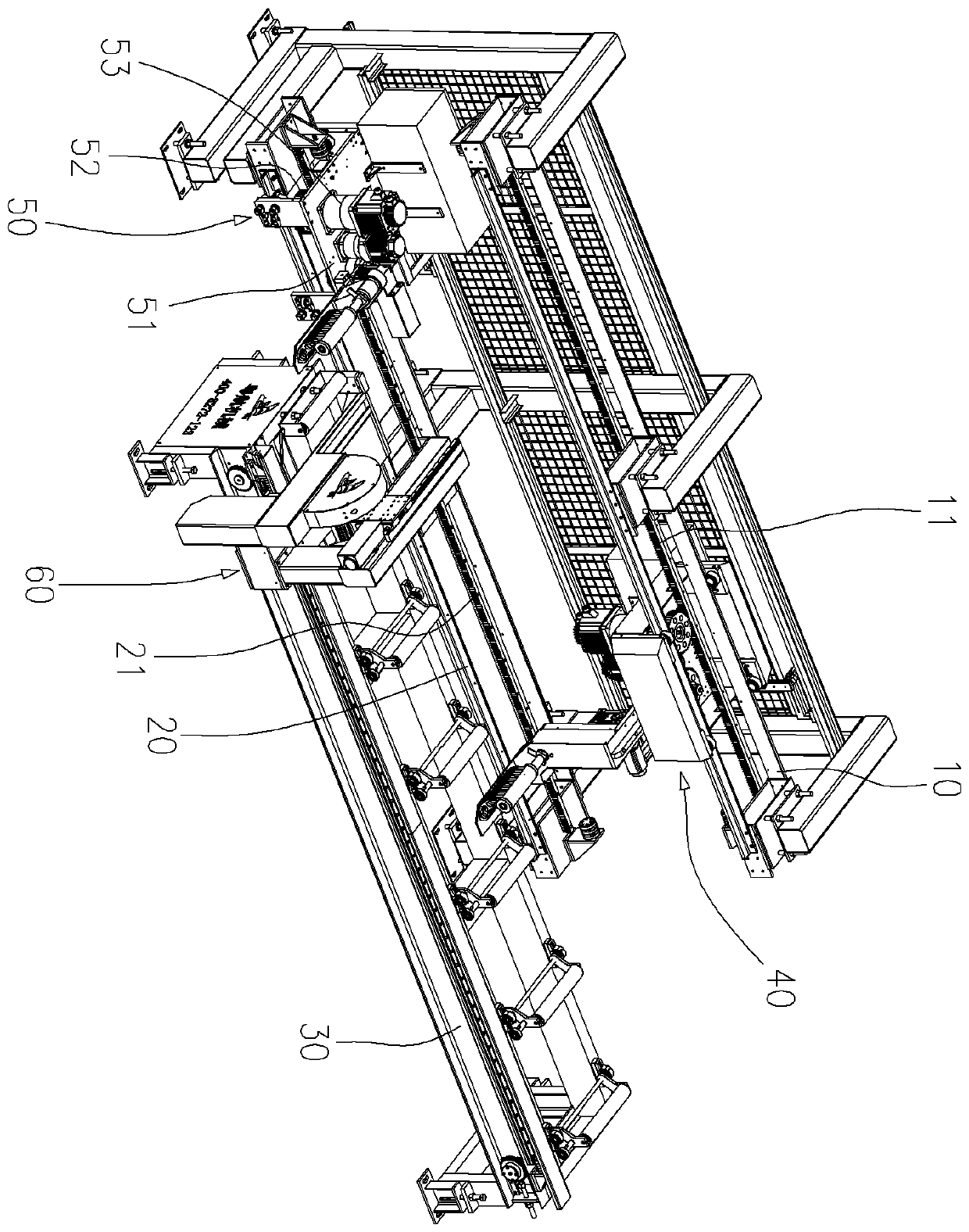

[0012] Such as Figure 1 to Figure 4 Shown is a kind of preferred specific implementation example of the present invention, a kind of 1000T pure electric three-head traction machine, comprises upper layer guide rail group 10, lower layer guide rail group 20, roller rack 30, the first traction head 40, the second traction The head 50 and the automatic interruption saw 60, the middle part of the upper guide rail group 10 is provided with a first rack 11, the middle part of the lower guide rail group 20 is provided with a second rack 21, and the first traction head 40 includes a first tractor 41 , the first drive gear 42 arranged in the first tractor 41 and meshed with the first rack 11 and the first servo drive gear 42 inverted at the bottom of the first tractor 41 and connected to the first drive gear 42 The motor 43 drives the first drive gear 42 to travel on the first rack 11 through the first servo motor 43 , thereby driving the first tractor 41 to move on the upper guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com