Propellant powder combustion speed calculation method

A calculation method and propellant technology, applied in chemical process analysis/design, etc., can solve problems such as calculating the burning rate of propellant, and achieve a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] Taking a certain three-base propellant as an example, the specific description of its burning rate calculation method is given below. The three-base propellant formula consists of:

[0055] code name NC(12.8) NG RDX NGU C 2

BYZGR 39 20 25.5 14.2 1.3

[0056] According to the established calculation method, the main component of the propellant is RDX.

[0057] (1) Combustion product H 2 O.CO 2 、H 2 , N 2 The number of moles of CO and CO are expressed as a, b, c, d, e respectively, and the combustion products are obtained by using the energy calculation method as follows:

[0058] Component a b c d e Mole number 10.37 4.40 3.53 9.29 12.34

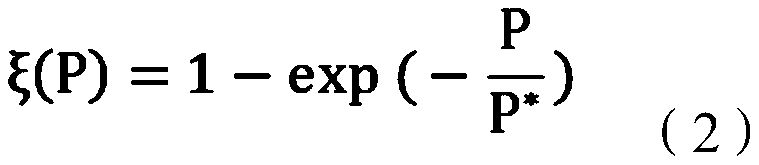

[0059] (2) ξ(P)=1-exp(-P / P*), P * Take 9.81MPa.

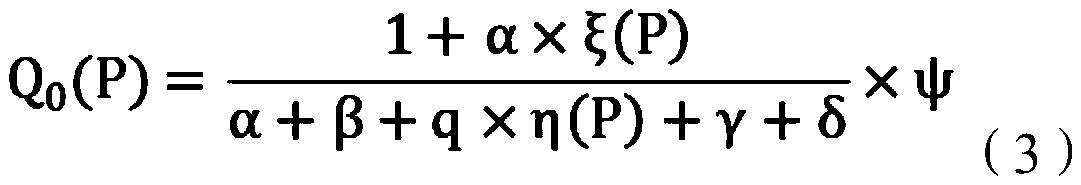

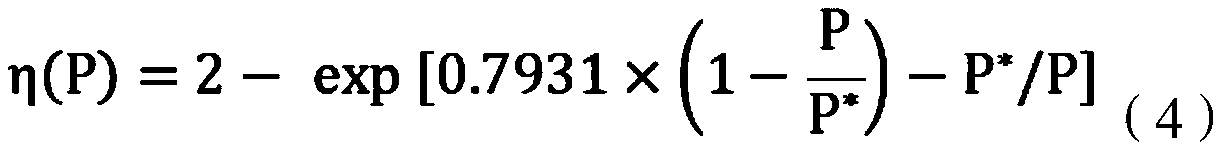

[0060] (3)

[0061]

[0062]

[0063] ψ is 0.93, α is 26%, β is 11.1%, q is 8.8%, γ is 23.2%, and δ is 30.9%.

[0064] (4) Burning rate of propellant: u=1.817×P×Q 0 (P) 2 × h H / ρ P

[0065] Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com