Bridge sling anchorage device pin shaft oiling device and oiling method thereof

A technology of refueling device and anchorage, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of lubricating oil consumption, affecting bearing capacity, less oil intake, etc., to improve the lubrication state, increase the service life, reduce the The effect of maintenance and replacement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

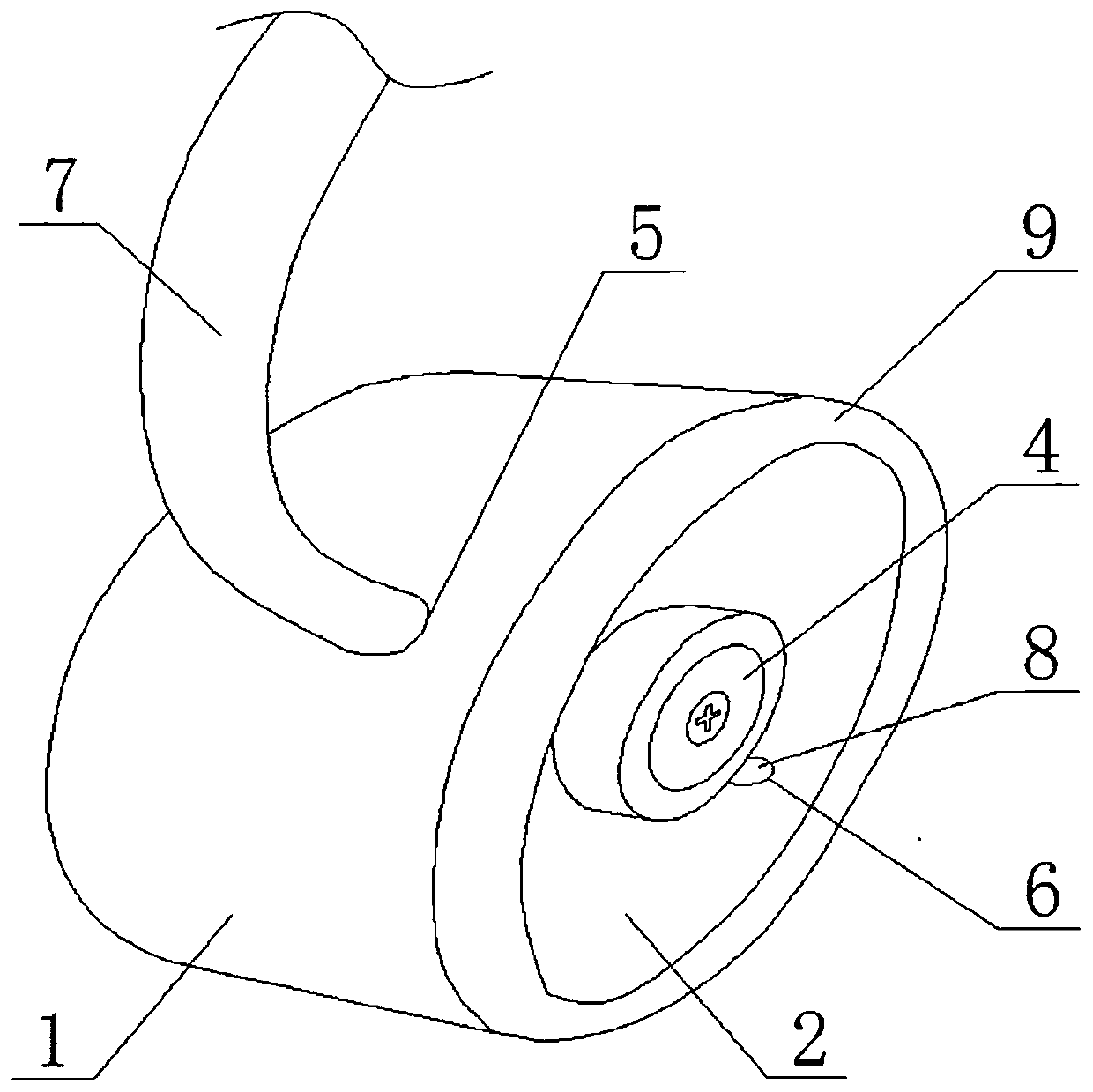

[0031] Such as figure 1 , figure 2 As shown, a bridge sling anchor pin refueling device in this embodiment includes a sealed tank 1, the rear end of the sealed tank 1 closes the front opening, and the open end of the sealed tank 1 is hollowed out to form a circular shape. Oil storage chamber 2, the inner diameter of the circular oil storage chamber 2 is larger than the diameter of the anchor pin shaft, the center of the closed end of the sealed tank 1 is equipped with a fastening bolt 3, and the front end of the fastening bolt 3 passes through the sealed tank 1 to seal The end extends into the circular oil storage chamber 2, the front end of the fastening bolt 3 is provided with a magnetic mechanism 4, the magnetic mechanism 4 includes a permanent magnet 4.1, and a built-in nut is arranged on the rear end surface of the permanent magnet 4.1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com