Building wall spraying device

A spraying device and wall surface technology, which is applied in the direction of architecture and building construction, can solve the problem of not being able to adjust the front and rear positions and distances of the spray pipe at the same time, and achieve the effect of improving the effect of smearing and the smearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

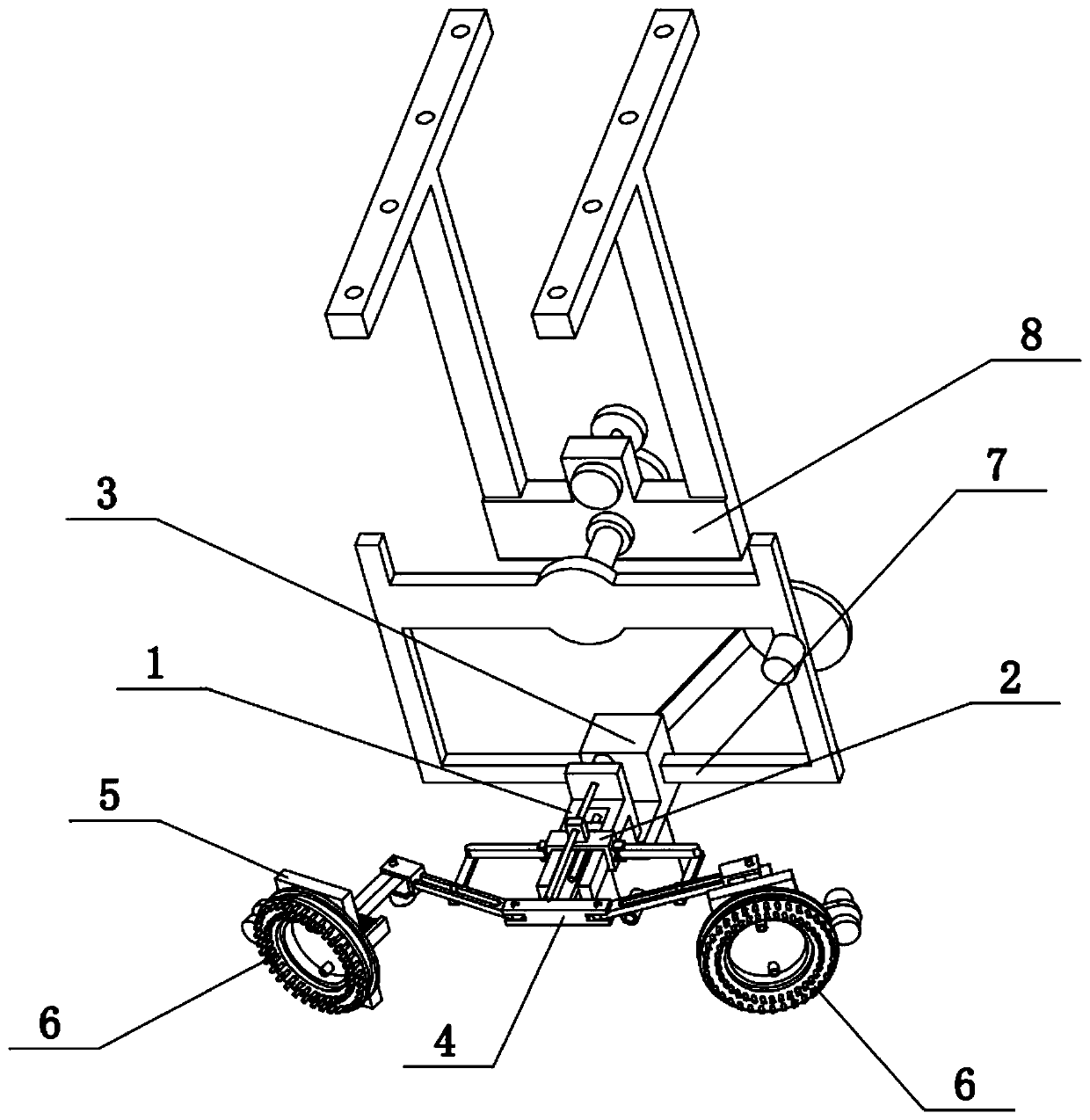

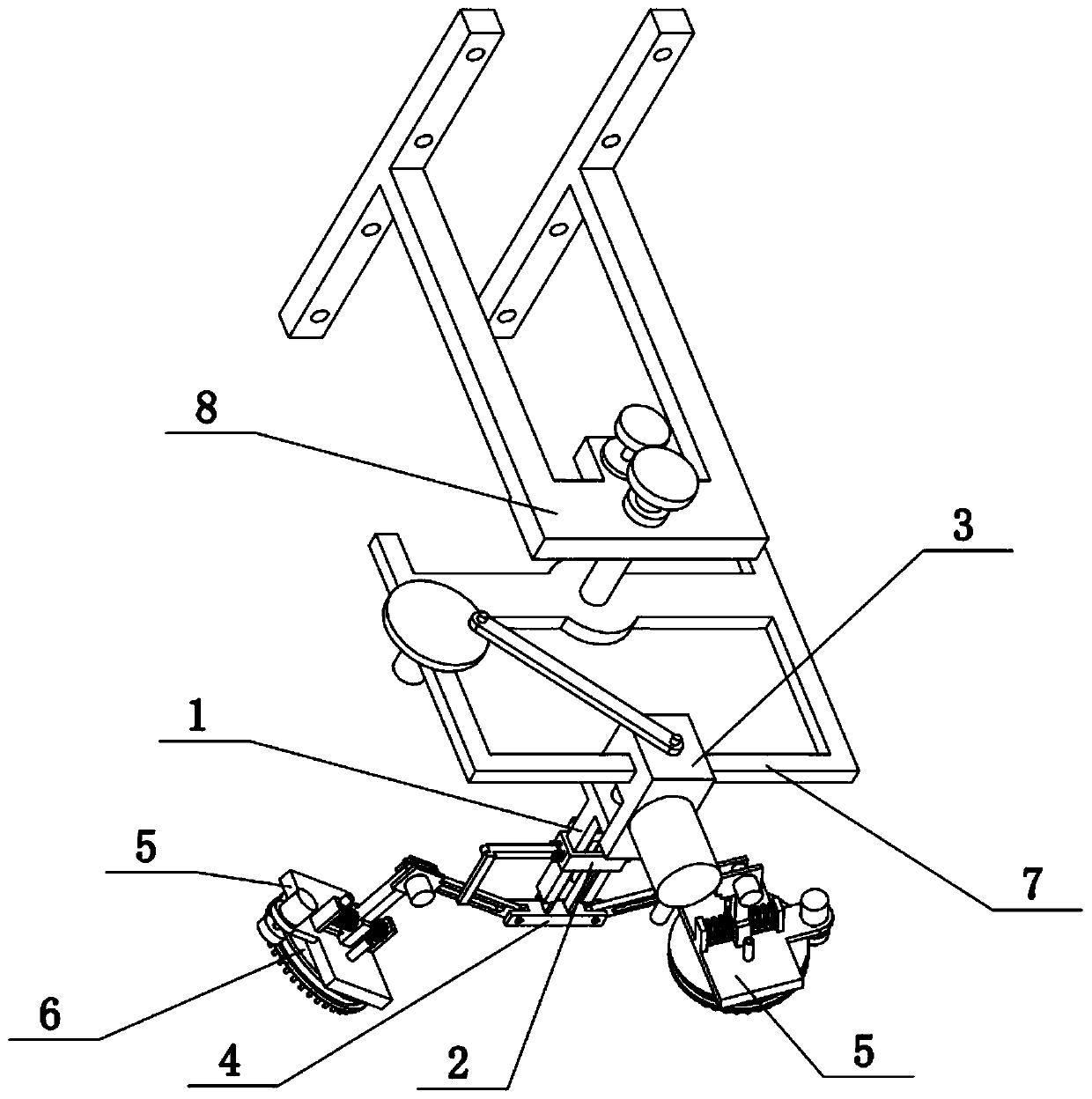

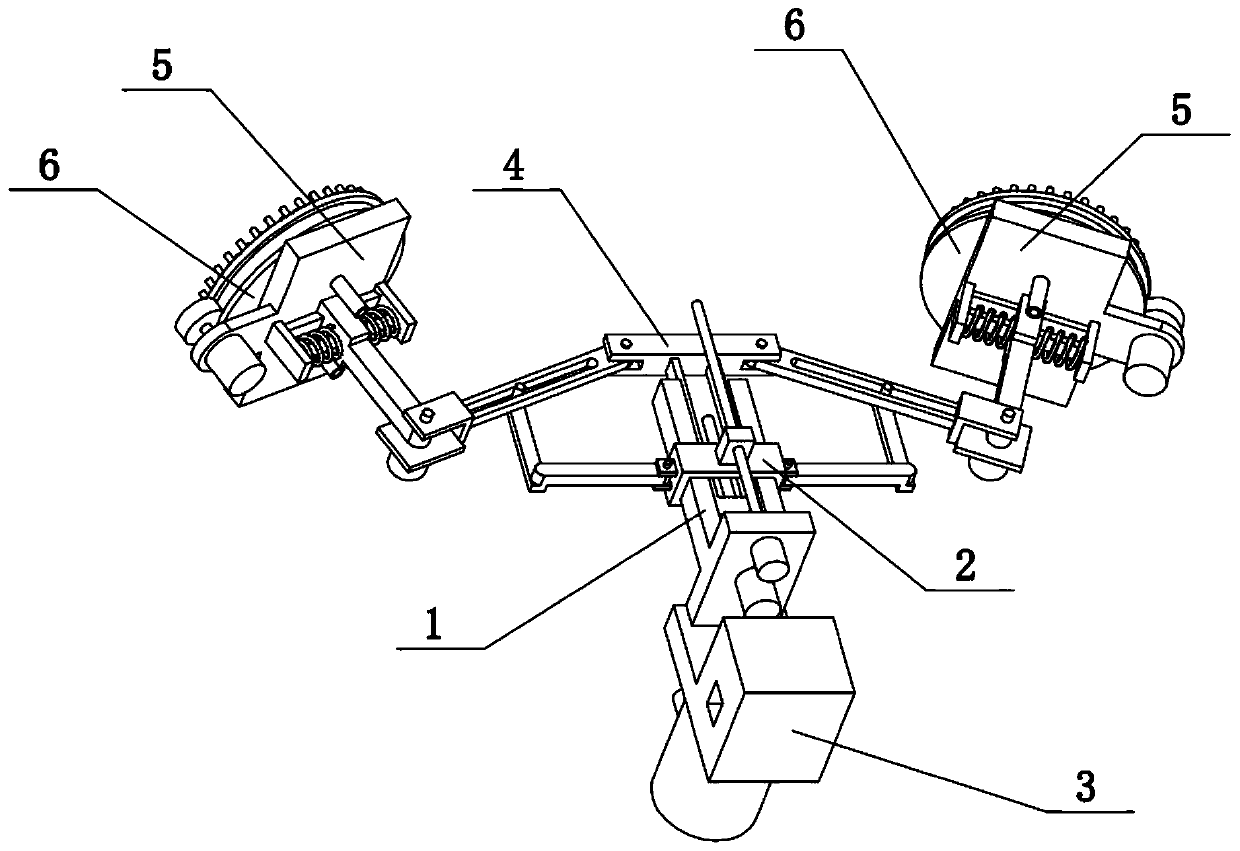

[0035] Combine below Figure 1-11 Describe this embodiment, the present invention relates to the field of building construction, more specifically, a building wall surface spraying device, including a flat seat 1, a flat groove 101, a screw 105, a slip ring 2, an L-shaped folding rod 201, a convex cylinder 202, middle seat 4, sliding hole rod 401, sliding hole 402, hinge seat 403, connecting rod 405, threaded hole block 406, vertical plate 5, material spray pipe 501 and arm lever 505, the present invention can adjust two simultaneously as required The front and rear positions and distances of the risers 5 are convenient for the spray pipes 501 on the two risers 5 to spray the building.

[0036]The flat seat 1 is provided with a flat groove 101, and the threaded hole block 406 is slidably connected to the flat groove 101. The threaded hole block 406 is fixedly connected with two connecting rods 405, and the other ends of the two connecting rods 405 are fixedly connected. There...

specific Embodiment approach 2

[0038] Combine below Figure 1-11 To illustrate this embodiment, the construction wall spraying device further includes a motor III404, which is fixedly connected to the two hinged seats 403, and the output shafts of the two motors III404 are fixedly connected to the two arms 505 respectively. When the output shafts of the two motors III404 rotate, they can respectively drive the two arm levers 505 to rotate on the two hinged seats 403, and then adjust the two vertical plates 5 to a position parallel to the building wall, which is convenient for the vertical plates 5 to rotate. The spray pipe 501 on the top sprays the wall surface.

specific Embodiment approach 3

[0040] Combine below Figure 1-11 Illustrate this embodiment, described building wall spraying device also comprises back seat 102, motor I103, motor II104, lead screw I105 and lead screw II106, the rear end of flat seat 1 is fixedly connected with back seat 102, and the back seat 102 is fixed The motor I103 and the motor II104 are connected, the output shaft of the motor I103 is fixedly connected with a lead screw I105, the output shaft of the motor II104 is fixedly connected with a lead screw II106, the lead screw I105 cooperates with the threaded hole block 406 through threads, and the lead screw 106 Cooperate with slip ring 2 through thread. When the output shaft of motor I103 rotates, it can drive the lead screw I105 to rotate on its own axis. When the lead screw I105 rotates on its own axis, it can control the threaded hole block 406 to slide back and forth on the flat groove 101; It can drive the lead screw II106 to rotate around its own axis, and when the lead screw I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com