Equipment for reducing content of trans-fatty acids in corn oil and process of equipment

A technology of trans fatty acid and corn oil, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of increasing, missing, and increasing blood viscosity, and achieve the effect of shortening time and reducing production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

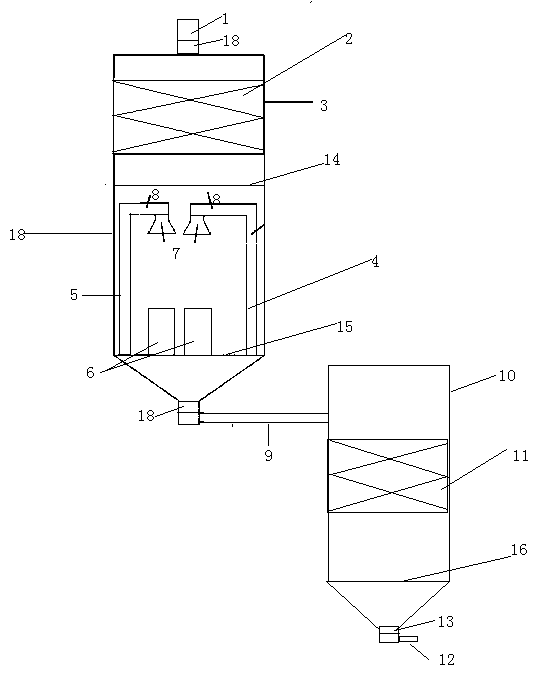

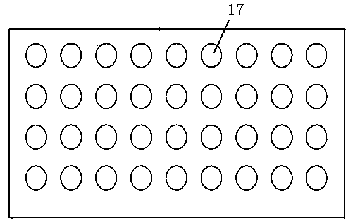

[0026] A treatment tower for reducing trans fatty acids in corn oil, comprising a deodorization tower 18, a pre-deacidification tower 18 on the top of the deodorization tower, and a post-deacidification tower 10 connected to each other through a deodorization tower oil outlet pipe 9, characterized in that the pre-deacidification The upper part of the tower is provided with an oil inlet pipe 1, and the inside is provided with a stainless steel mesh 2, and a first partition 14 is arranged between the pre-deacidification tower and the deodorization tower; the second partition 15 is arranged inside the deodorization tower, and the second A vertical infusion pipe 5, two oil receiving cups 6, and a longitudinal infusion pipe 4 are arranged in sequence on the partition, wherein the vertical infusion pipe is vertically connected to the second partition tower 15, and its upper end is connected to the nozzle (7) through the horizontal oil pipe (8) The post-deacidification tower 10 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com