Two-step calendering device for graphite and calendering method

A calendering device and graphite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of excessive graphite peeling force, residual graphite debris, production troubles of downstream customers, etc., to achieve convenient use and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

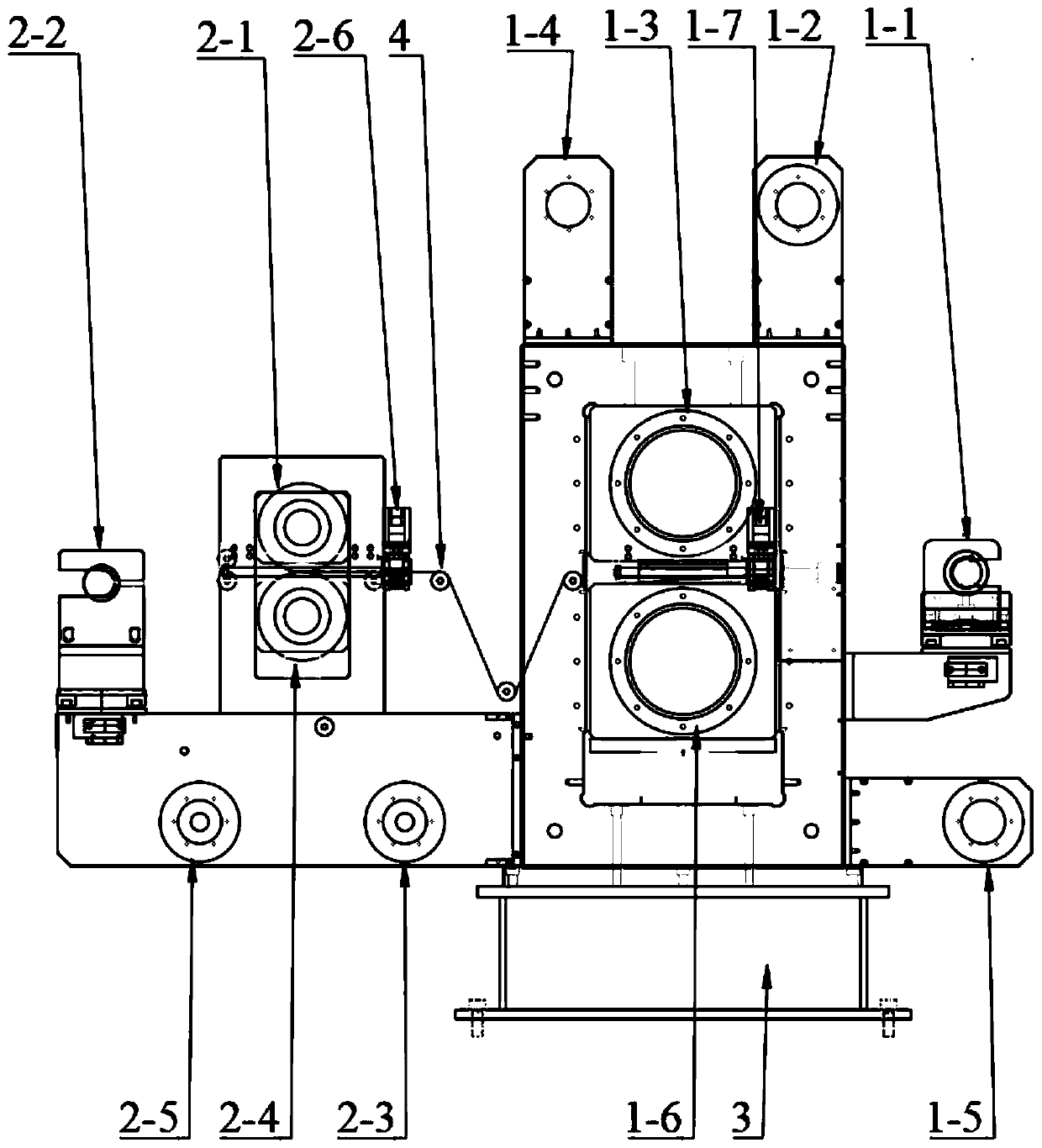

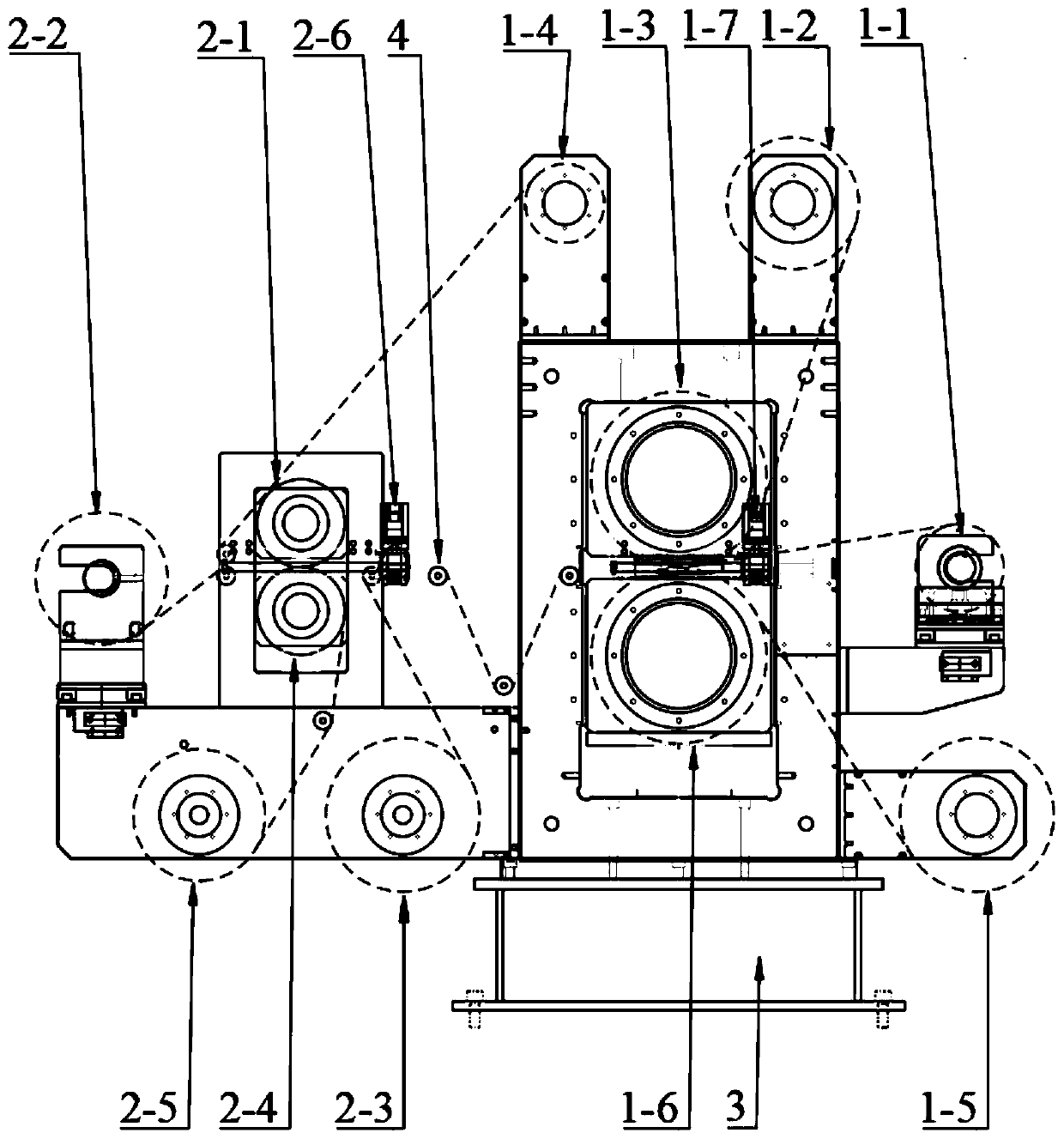

[0024] Such as figure 1 As shown, a two-step graphite calendering device includes a main calendering structure 1, and the main calendering structure includes a graphite unwinding reel 1-1, a cover film unwinding reel 1-2, a main calendering upper roll 1-3, and a cover film rewinding reel 1 -4. The first release film unwinding reel 1-5 and the main calendering lower roll 1-6 are characterized in that they also include an additional secondary calendering and bonding mechanism 2, and the secondary bonding and calendering structure includes secondary bonding and calendering Upper roll 2-1, graphite reel 2-2, first release film reel 2-3, second lamination and calender lower roll 2-4, second release film unwinder 2-5 and second servo motor 2-6, the secondary lamination and calendering upper roll 2-1 is installed on the discharge end of the main calendering structure 1, the main calendering structure 1 is installed on the mounting frame 3, and the secondary lamination and calendering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com