Ink pumping and cleaning method, device, equipment and printer for printer nozzle

A printer and nozzle technology, applied in the field of printer nozzle cleaning and printer nozzle ink extraction cleaning, can solve problems such as low cleaning efficiency, inability to clean nozzles, nozzle damage, etc., and achieve the effect of improving efficiency and effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

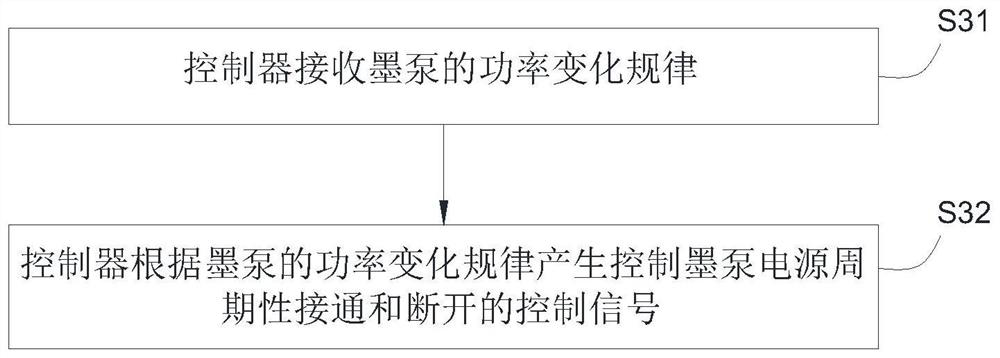

[0036] Such as figure 1 As shown, the present embodiment provides a method for cleaning nozzles of a printer by pumping ink, and the method includes:

[0037] S1. Obtain the number of ink pumping and cleaning times of the nozzle and the ink pumping time for each ink pumping and cleaning;

[0038] Specifically, when cleaning the nozzle, the ink impurities in the nozzle can be sucked clean by repeatedly pumping ink. After drawing ink for a certain period of time, let it stand for a period of time to ensure that the ink can be replenished after drawing the ink, and keep the internal and external pressure of the nozzle consistent so as to effectively avoid physical damage to the nozzle. Users can flexibly choose the times of ink pumping and cleaning according to the equipment usage. The ink pumping time described in this embodiment refers to the duration of ink pumping by the ink pump during one ink pumping and cleaning process.

[0039] S2. According to the number of times of ...

Embodiment 2

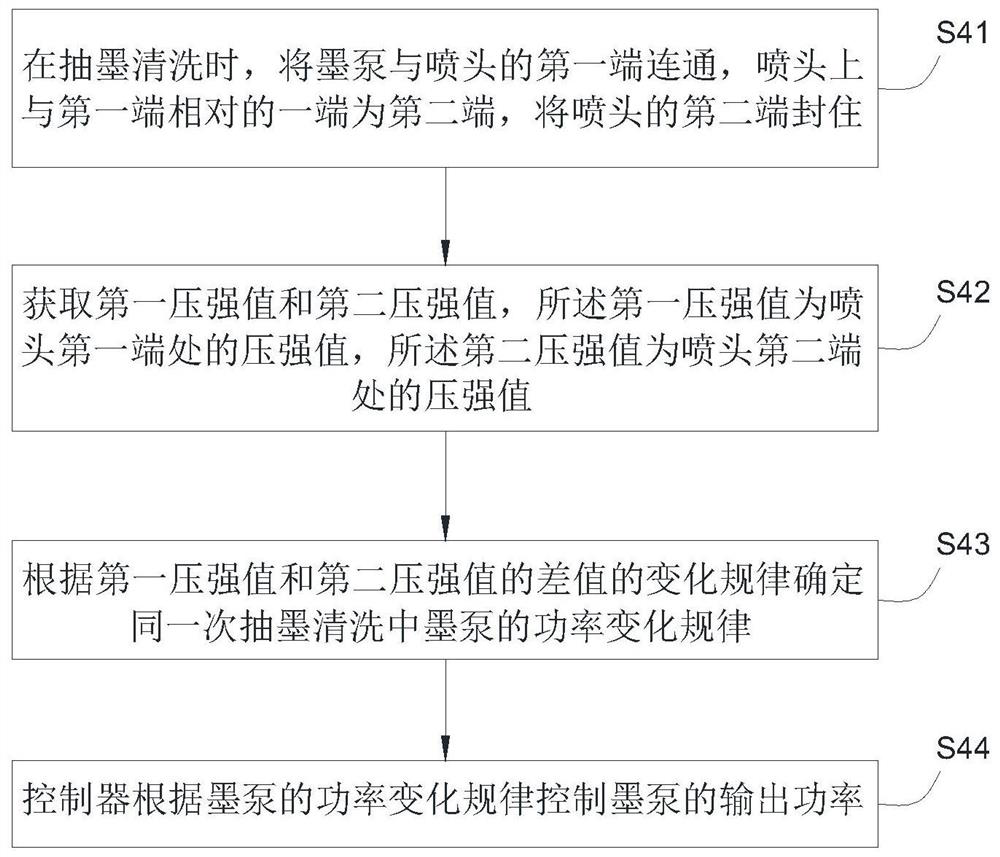

[0052] In this embodiment, the variation law of the power of the ink pump is as follows: the power of the ink pump decreases successively according to the sequence of times of pumping ink.

[0053] At the beginning of ink pumping, there are many waste ink impurities in the nozzle, and the clogging of the nozzle is more serious. At the beginning of ink pumping, a greater force of ink pumping can be used to quickly pump out the waste ink impurities in the nozzle. suck it out. After the previous ink pumping, the blockage of the nozzle has been alleviated. At this time, the ink pumping force can be appropriately reduced to avoid damage to the nozzle caused by excessive suction. Therefore, in this embodiment, the ink pumping power of the number of ink pumping performed first is relatively high, so that the nozzle is sucked with greater strength, so as to quickly and powerfully pump out the waste ink in the nozzle. After the previous suction operation, the blockage of the nozzle gr...

Embodiment 3

[0055] In this embodiment, the variation law of the power of the ink pump is as follows: the reduction of the power of the ink pump in the next pumping of ink compared to the power of the ink pump in the previous pumping of ink decreases with the increase of the time of the previous pumping of ink .

[0056] In the process of cleaning the nozzle by pumping ink for many times, if the previous time of pumping ink is longer, the amount of waste ink sucked is more, and the dredging of the nozzle after pumping ink is better. Reduce the power of the ink pump so that the strength of ink pumping matches the current condition of the nozzle. On the contrary, if the previous ink pumping time is short and the nozzle is still clogged to a certain extent after ink pumping, then the power of the ink pump can be appropriately increased for the next ink pumping, thereby increasing the ink pumping effect. For example, if the cleaning method of ink pumping twice is adopted, if the first ink pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com