Cross beam for viaduct type gantry machining center

A technology for viaducts and beams, used in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of insufficient beam rigidity, increased torsional deformation of beams, and large overturning moment, so as to facilitate on-site management and reduce overturning moment. , the effect of improving the versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

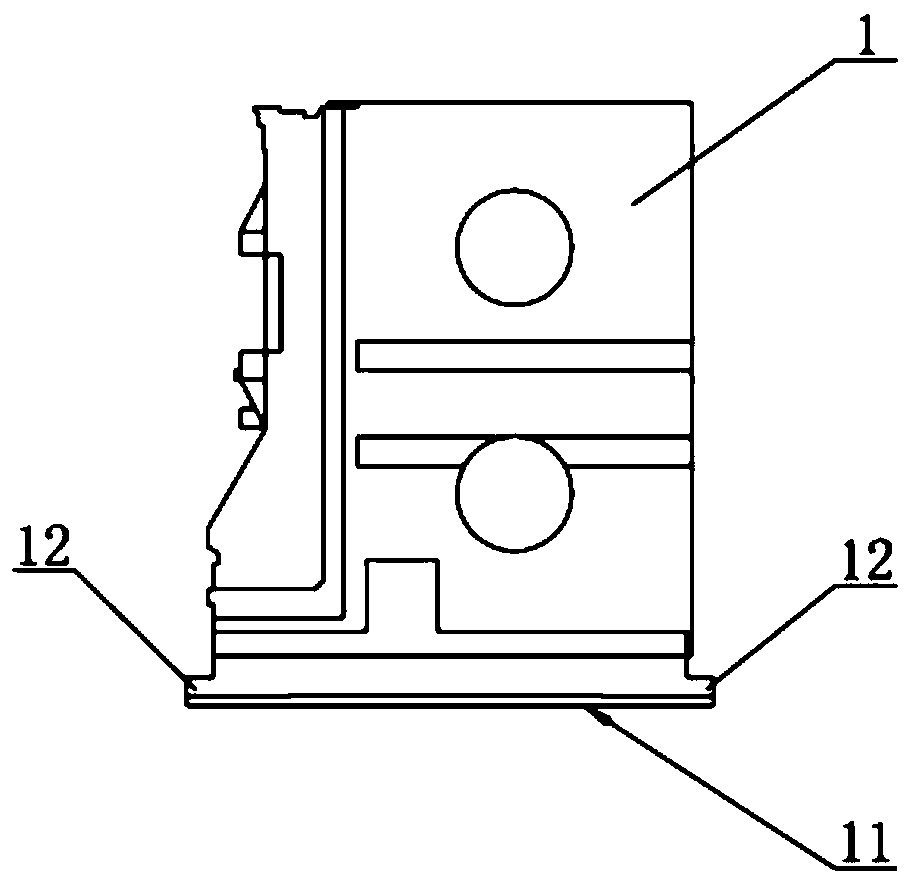

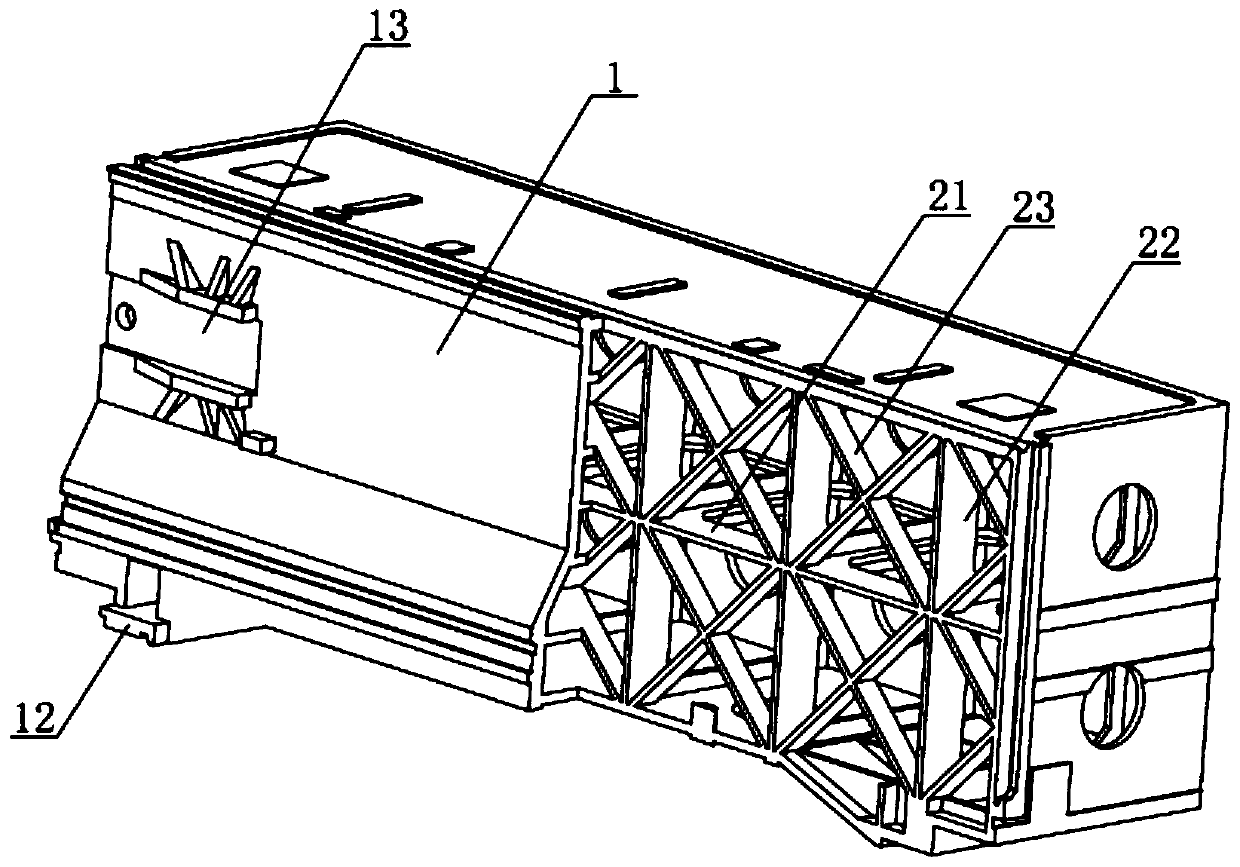

[0030] The beam used for the viaduct-type gantry machining center of Example 1, as shown in the figure, includes a beam body 1, which is a box structure, and the inner cavity of the beam body 1 is integrally connected with a reinforcement mesh, and the reinforcement mesh It is composed of staggered ribbed plates; the bottom surface of the beam body 1 is provided with two slider mounting surfaces 11, the beam body 1 is a left-right symmetrical structure, and the two slider mounting surfaces 11 are symmetrically arranged left and right, and the front side of the bottom of the beam body 1 and the rear side are provided with two protruding bosses 12, the front side and the rear side of each slider mounting surface 11 correspond to a boss 12 respectively, and the bottom surface of each boss 12 is flush with a slider mounting surface 11 flat.

[0031] In Embodiment 1, a first positioning groove 17 and a second positioning groove 18 are respectively opened on the left and right sides...

Embodiment 2

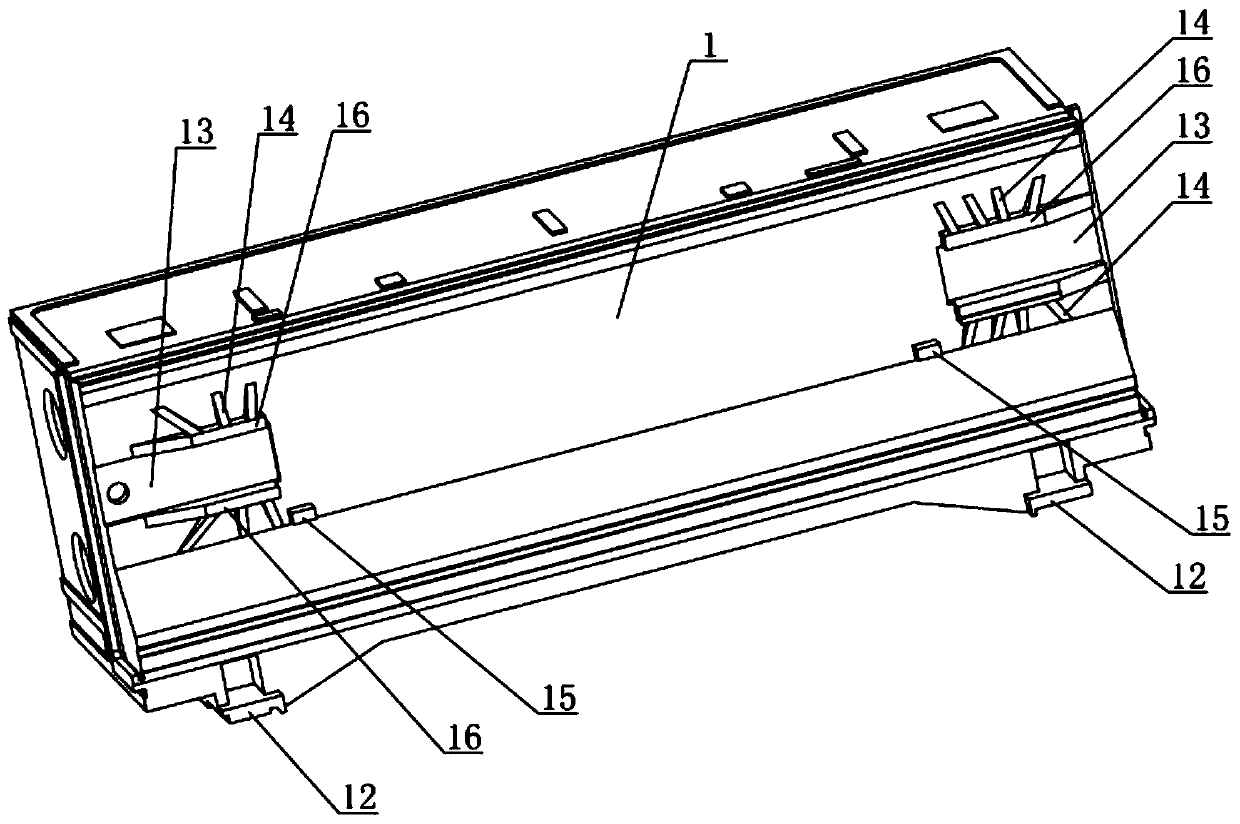

[0033] The difference between the beam used for the viaduct-type gantry machining center of Embodiment 2 and Embodiment 1 is that in Embodiment 2, two screw mounting parts 13 are provided on the front side of the beam body 1, and the two screw mounting parts 13 The left and right are arranged symmetrically, and the outer side of each screw mounting part 13 is provided with a plurality of triangular ribs 14 distributed radially at intervals centered on the screw mounting part 13, and the plurality of triangular ribs 14 are integrally connected with the beam body 1; Two limit blocks 15 are connected to the front side of the beam body 1 , and the two limit blocks 15 are located between the two lead screw mounting parts 13 .

[0034] In Embodiment 2, a trapezoidal rib 16 arranged horizontally is connected to the upper side and the lower side of each screw mounting part 13, and each trapezoidal rib 16 is connected with a plurality of triangular ribs 14 distributed radially at interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com