Automobile structural part stamping die and quick positioning tool for die

A technology for automobile structure and stamping dies, which is applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as irregular structure, and achieve the effect of improving functional structure and functional structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

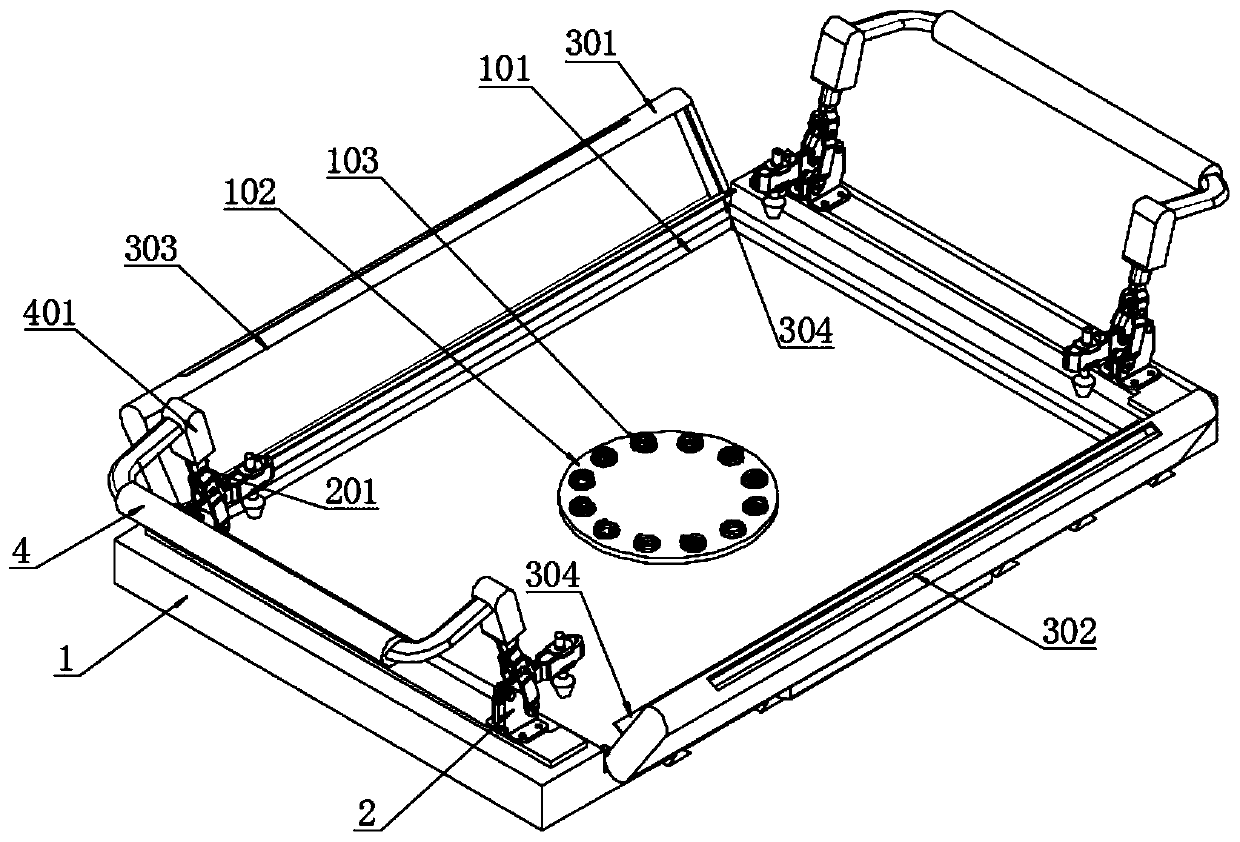

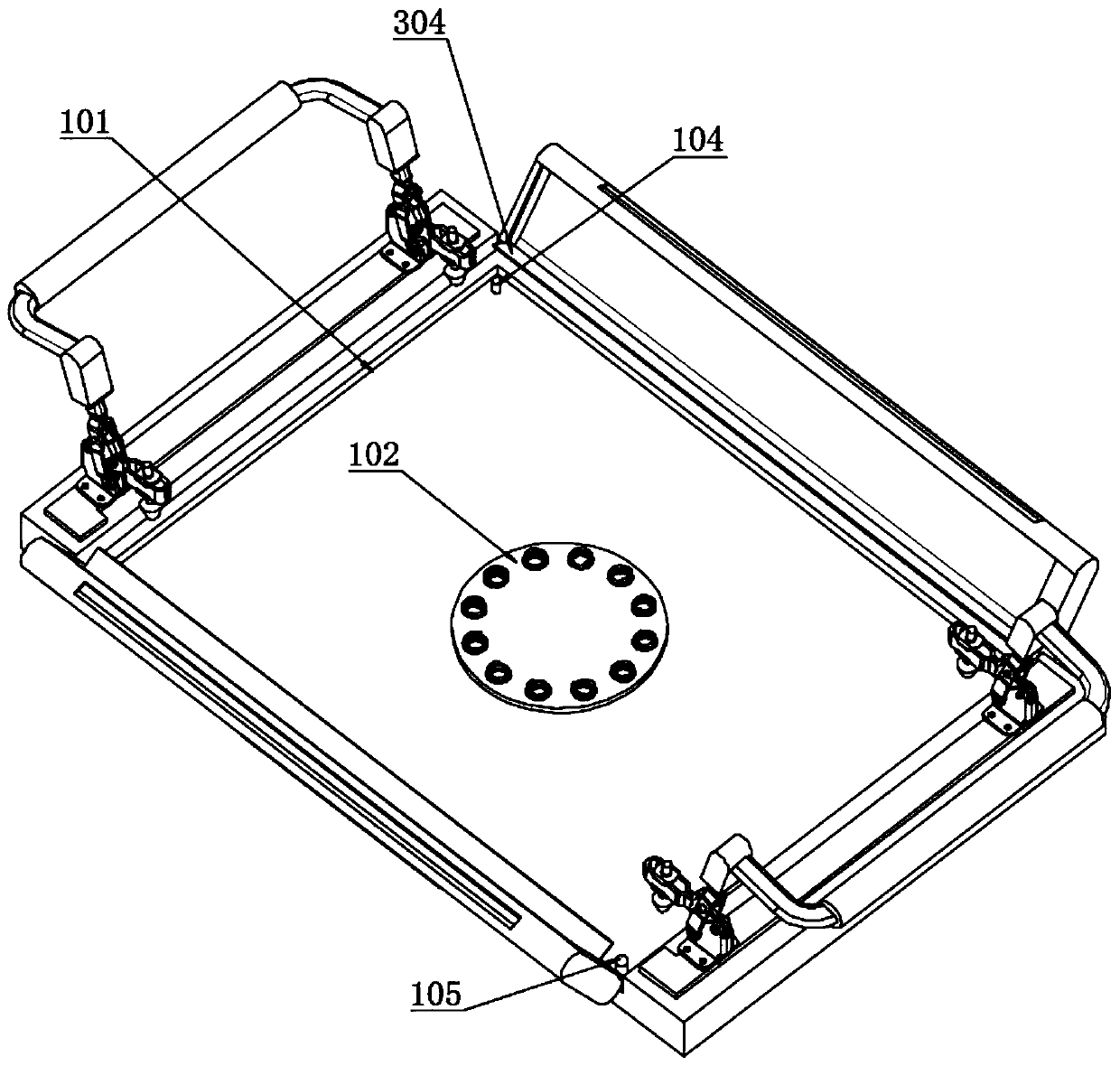

[0031] as attached figure 1 to attach Figure 11 Shown: ( Figure 1 to Figure 9 For this structure diagram, Figure 10 and Figure 11 It is the schematic diagram of template and punch equipment workbench installation mode under the prior art that this design is convenient for comparison explanation).

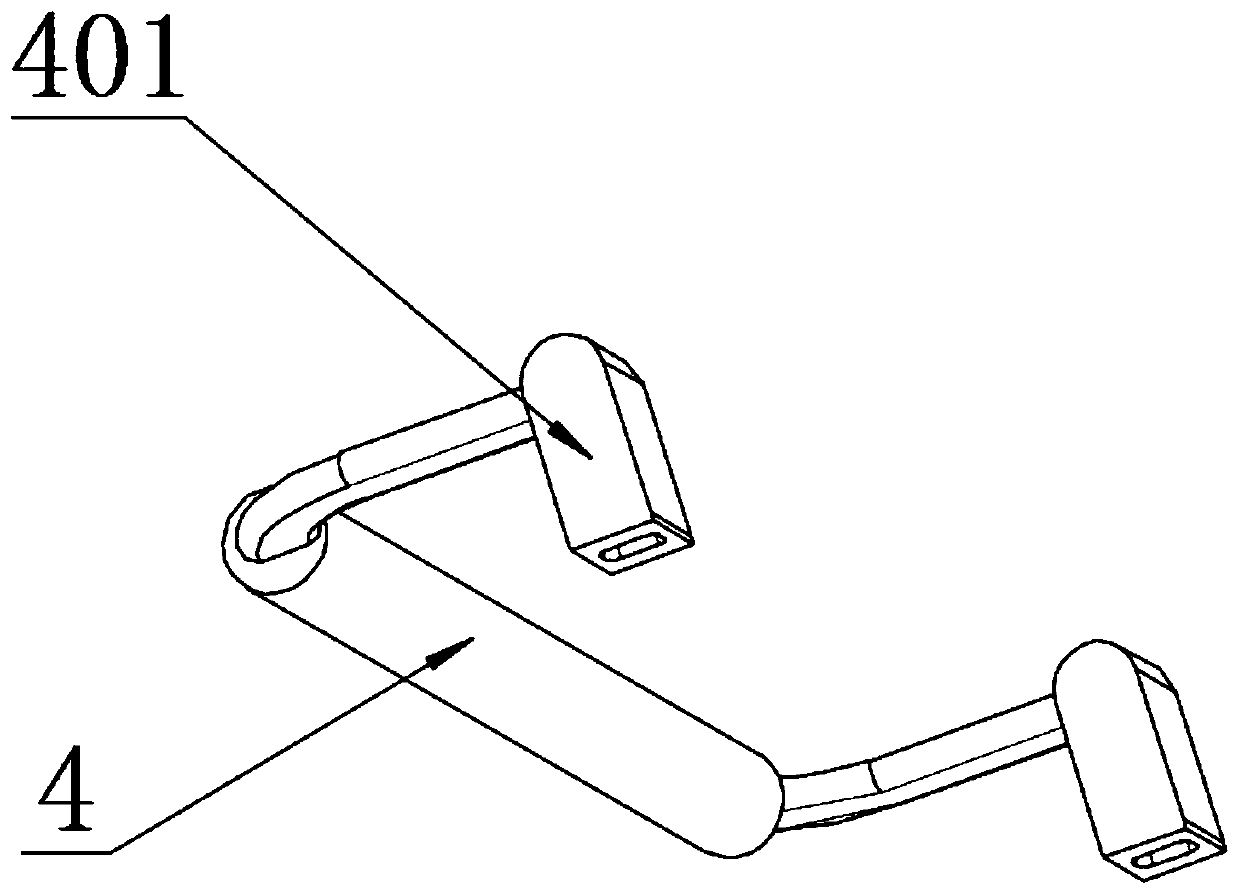

[0032]The present invention provides stamping molds for automotive structural parts and quick positioning tooling for molds, including a mold base 1, an inner panel 101, a middle panel 102, a compression spring 103, a first guide column 104, a second guide column 105, and a clamp 2. Fixture handle 201, swivel seat 3, stop seat 301, discharge port 302, guide groove 303, overboard 304, connecting pressure handle 4, buckle sleeve 401, mold body 5, lower template 501, bottom groove 502, bottom pad 503, the front flow plate 504, the rear flow plate 505 and the guide hole 506; the mold base 1 is a rectangular mold base, which is provided with a rectangular sinker, and a circle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com