A microwave solidification equipment for uranium tailings reservoir beach surface

A technology of microwave solidification and tailings storage, which is applied in the directions of transportation and packaging, radioactive purification, chemical instruments and methods, etc. It can solve the problems of pollution, reduce the volume of radioactive waste, and poor treatment effect, and achieve good treatment effect and heating The effect of fast speed and uniform heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

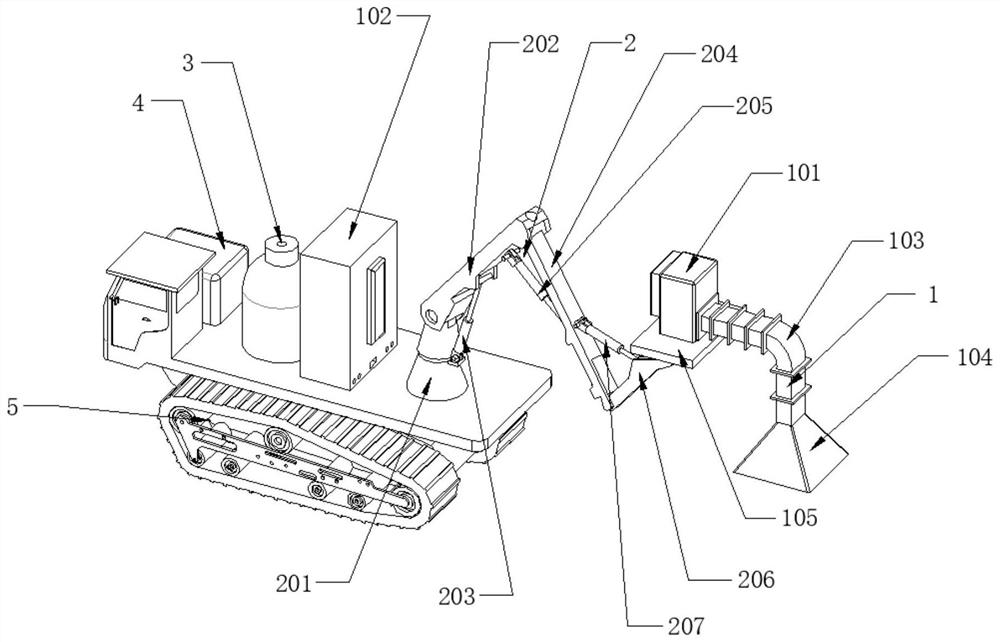

[0029] refer to figure 1, a microwave curing equipment for the beach surface of uranium tailings reservoir, characterized in that it includes: a microwave heating system 1, a lifting device 2, an exhaust gas treatment system 3, a power supply system 4 and a moving device 5; the microwave heating system 1 passes through the The support plate 105 is fixedly connected with the lifting device 2, the lifting device 2 is rotatably arranged on the mobile device 5, the exhaust gas treatment system 3 and the power supply system 4 are fixed on the mobile device 5; The microwave heating system 1 , the lifting device 2 , the tail gas treatment system 3 and the moving device 5 are all electrically connected to the power supply system 4 .

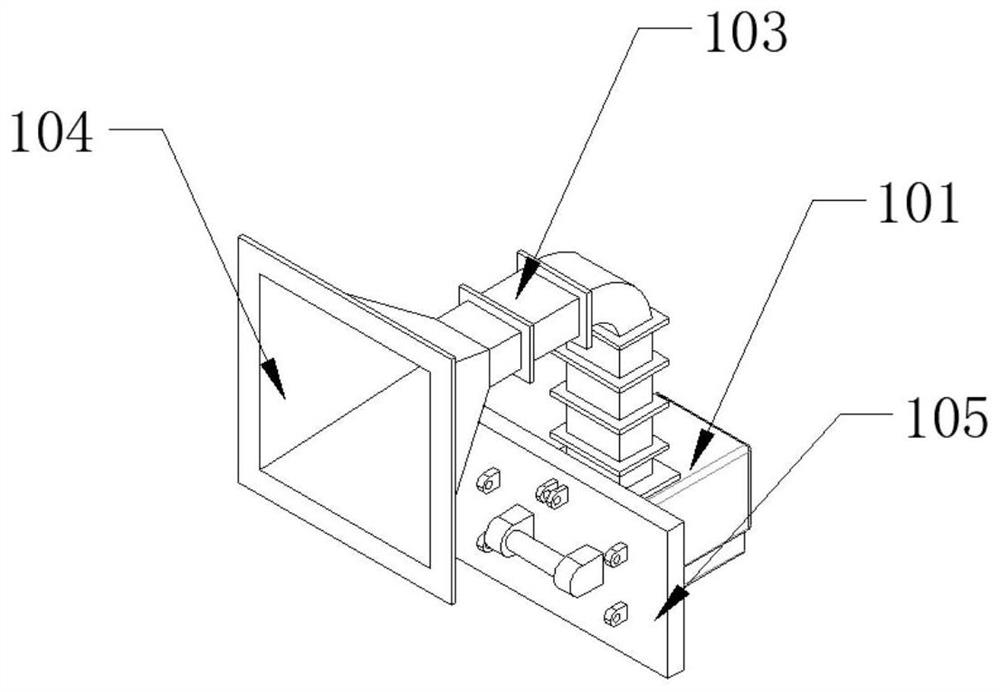

[0030] according to figure 1 , the microwave heating system 1 includes: a microwave generator 101, a microwave control cabinet 102, a waveguide 103, a horn feeder 104 and a support plate 105; the microwave generator 101 is fixed on the support plate 105...

Embodiment 2

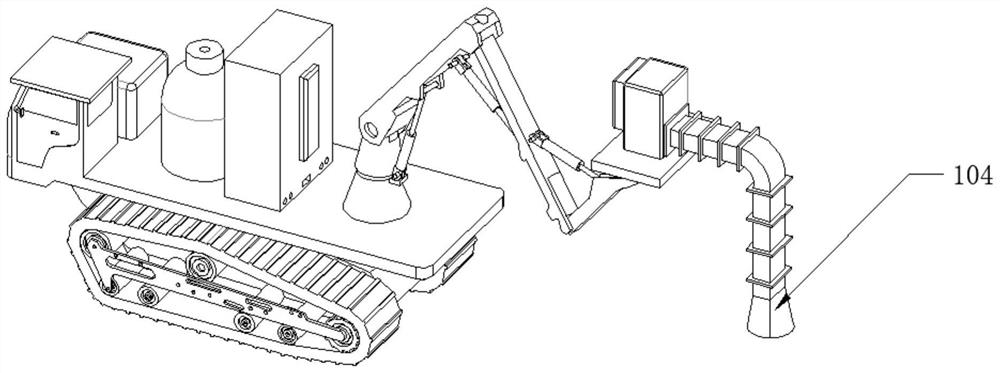

[0040] As another embodiment of the present invention, such as figure 2 As shown, the structural principle of this embodiment is similar to that of Embodiment 1, and the difference from Embodiment 1 is that the microwave heating system 1 of this embodiment is used for deep microwave curing of the beach surface of the uranium tailings reservoir, and the horn feeder The bell mouth of 104 is circular, such as Figure 4 As shown, the diameter of the bell mouth is 30-50cm, and the length of the waveguide is lengthened to realize the sintering treatment of the deep part of the uranium tailings.

[0041] When performing deep microwave solidification on the beach surface of uranium tailings reservoir, a deep microwave heating system is used, and the shape of the horn feeder 104 is circular. The working principle of the deep microwave heating system used in this embodiment is similar to that of Embodiment 1, except That is, before microwave heating, holes need to be drilled and distr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com