Pressure pipeline damage prediction method based on sequential analysis

A time series analysis and pressure pipeline technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of stable fluctuation of stress values, distortion of predicted values, and lack of time to prepare emergency plans, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

[0081] A pressure pipeline damage prediction method based on time series analysis, comprising the following steps:

[0082] Step 1, obtain the stress value of the pressure pipeline through the sensor unit, and the collection frequency of the stress value is f=2 times / day;

[0083] In step 2, the sequence of stress values accumulated in the time course of 70 days is recorded as:

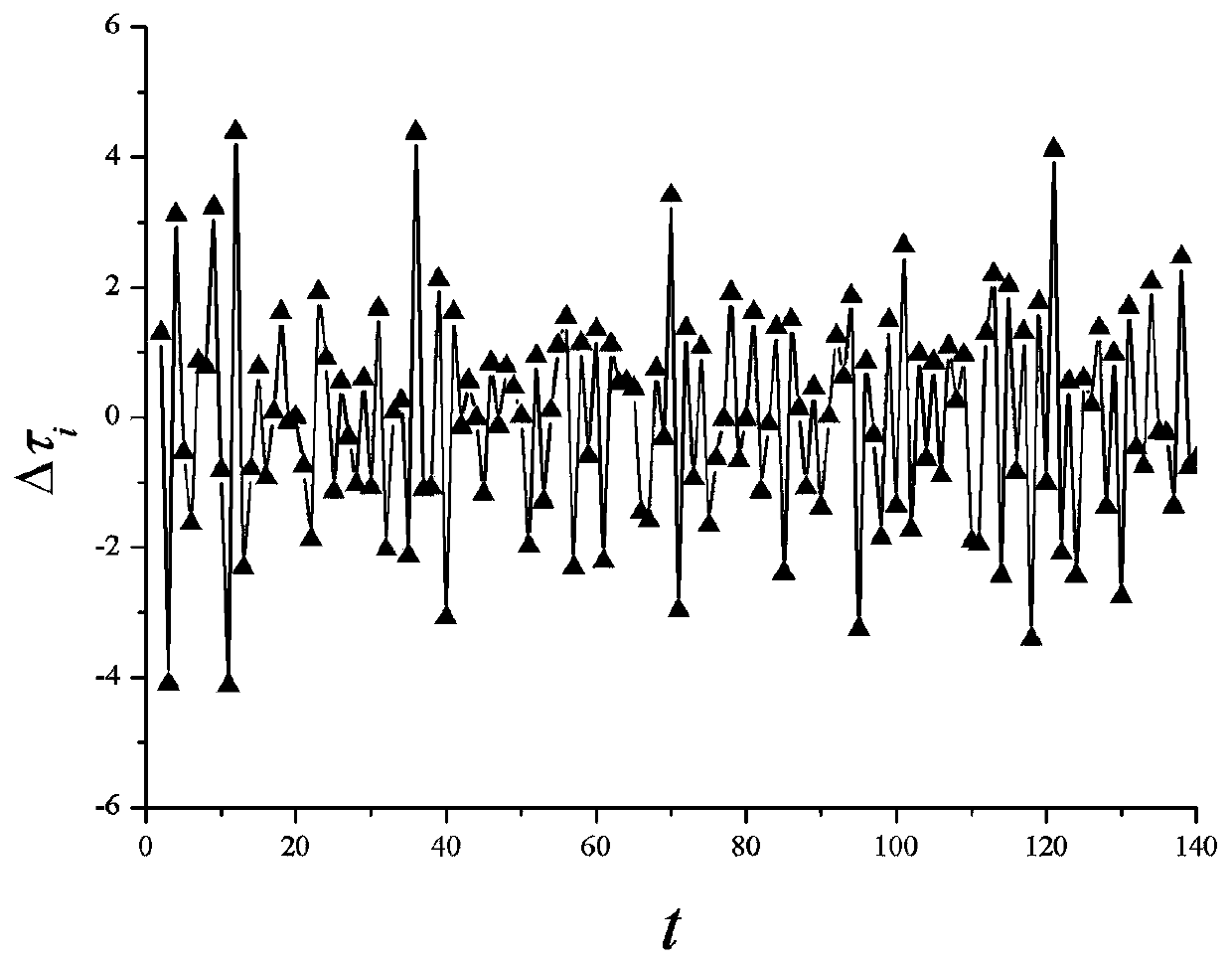

[0084] {τ t}={τ 1 ,τ 2 ,...τ 140} (1)

[0085] The above stress value sequence time history curve is as follows figure 1 shown;

[0086] Assuming that the stress value sequence is a quasi-steady state sequence, that is, the stress value fluctuates in a small range around a certain constant value, and its fluctuation amplitude conforms to a normal distribution. The above-mentioned stress value sequence time history curve is as follows: figure 1 shown;

[0087] Step 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com