An automatic lifting vertical feeding equipment for high-rise curtain wall panels

A technology of feeding equipment and curtain wall, applied in the directions of transportation, packaging, conveyors, etc., can solve the problems of inability to realize circulating transportation of wall blocks, low lifting efficiency, long wear time, etc., to improve practicability, improve lifting speed, and improve The effect of simplicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

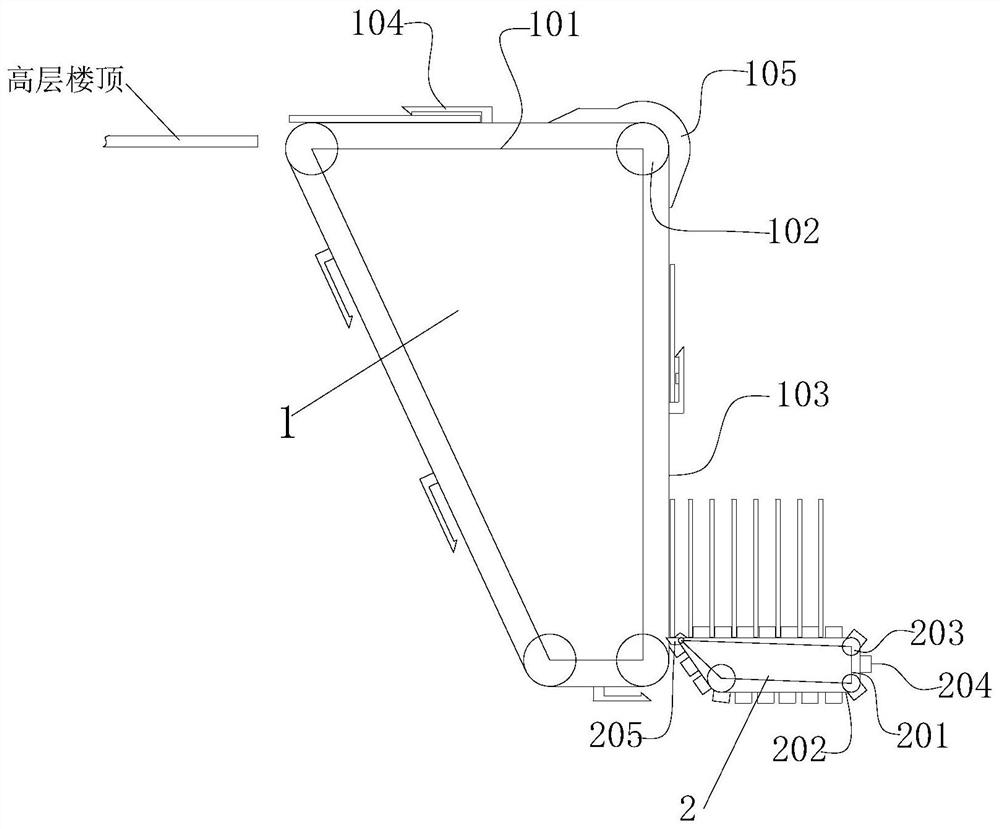

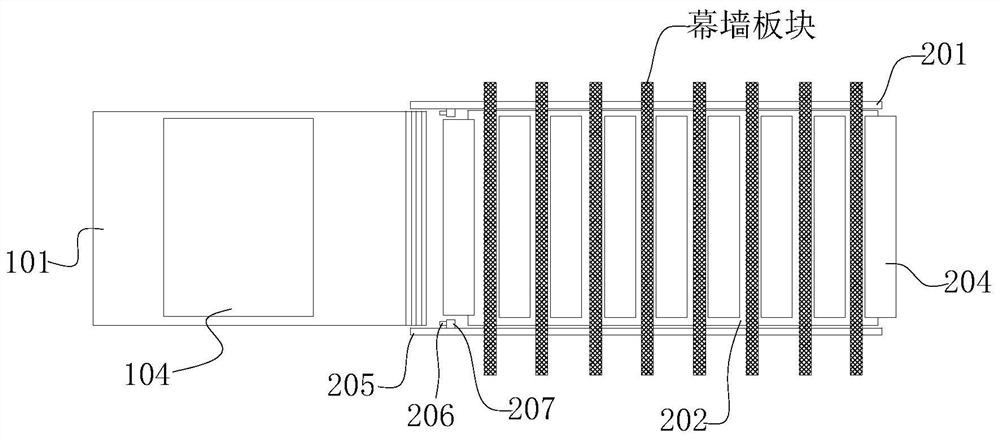

[0036] see Figure 1-6 , is an automatic lifting vertical feeding equipment for high-rise curtain wall panels, which transports the ground curtain wall panels to the top of high-rise buildings. The equipment includes: a lifting device 1 and a feeding device 2, the feeding device 2 is set on the ground, and the lifting device 1 is fixed on One end of the feeding device 2, the feeding device 2 provides upright curtain wall panels to the lifting device 1, and the lifting device 1 lifts the curtain wall panels on the feeding device 2 to the top of the high-rise building, and the top of the lifting device 1 is level with the top surface of the high-rise building. together;

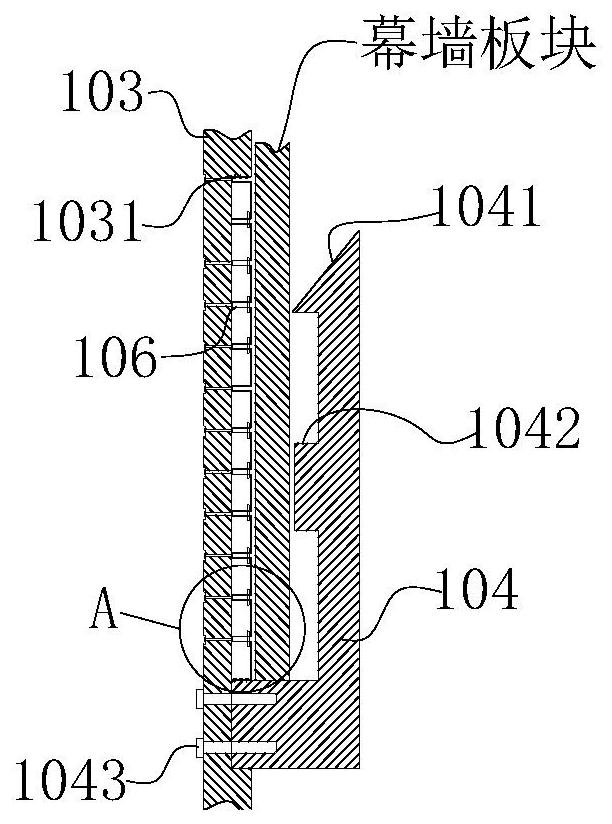

[0037] The lifting device 1 includes a first conveyor belt 103, the first conveyor belt 103 is set as a closed structure, the inner ring of the first conveyor belt 103 is provided with a roller 102, and there are at least four rollers 102, according to the drawings in the specification, one of the rollers 102 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap