A control method of an electrohydraulic power steering system

A technology of hydraulic power steering and control method, which is applied in the direction of power steering mechanism, steering mechanism, fluid steering mechanism, etc., which can solve the problems of poor emergency control effect and achieve the effect of improving effect, good effect and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

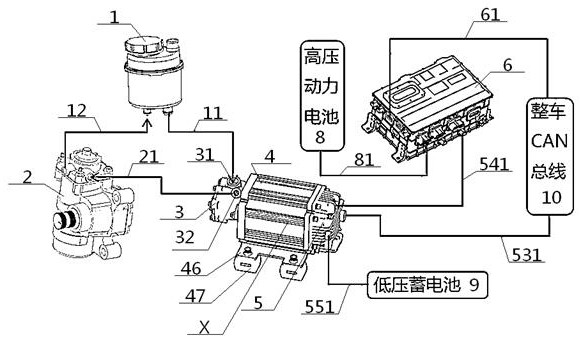

[0067] see Figure 1 to Figure 7 , a control method of an electro-hydraulic power steering system, the electro-hydraulic power steering system includes a motor 4, a high-voltage controller 6, a low-voltage controller 7 and a vehicle CAN bus 10, the motor 4 includes a motor stator 42, a high-voltage motor The rotor 43 and the low-voltage motor rotor 44, the high-voltage motor rotor 43, and the low-voltage motor rotor 44 share a motor stator 42. The high-voltage motor rotor 43 is electrically connected to the high-voltage power supply 8 through the high-voltage controller 6. The controller 7 is electrically connected to the low-voltage power supply 9, and the high-voltage controller 6 is connected to the CAN bus 10 of the vehicle through a high-voltage signal line 61. The vehicle CAN bus 10 is used for signal connection;

[0068] The control method includes a normal communication strategy, and the judging standard of normal communication is that the signal transmission between ...

Embodiment 2

[0072] Basic content is the same as embodiment 1, the difference is:

[0073] The working time of the low-voltage motor rotor 44 includes the shortest working time and the longest working time, wherein, within the shortest working time, the low-voltage controller 7 controls the low-voltage motor rotor 44 to run continuously, and outside the longest working time, the low-voltage controller 7 7 then control the low-voltage motor rotor 44 to stop running (can stop automatically). When the low-voltage motor rotor 44 is in the shortest working time, if the vehicle speed drops to a certain value, the low-voltage controller 7 controls the low-voltage motor rotor 44 to stop running. When the low-voltage motor rotor 44 works between the shortest working time and the longest working time, the driving motor of the whole vehicle will run with reduced power.

Embodiment 3

[0075] Basic content is the same as embodiment 1, the difference is:

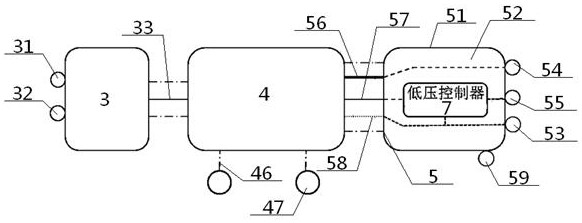

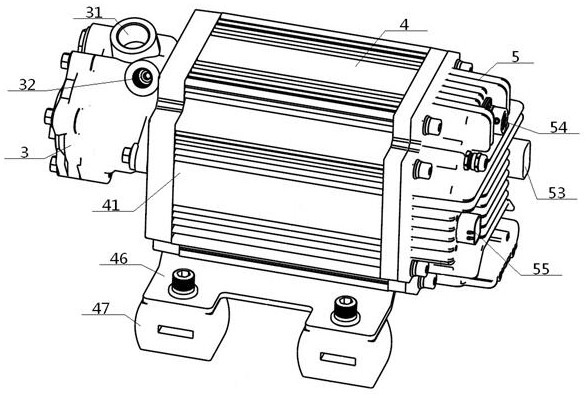

[0076] The electro-hydraulic power steering system includes an oil pump 3, a motor 4, an integrated casing 5, a high pressure controller 6 and a low pressure controller 7, the input shaft of the oil pump 3 is connected to the output shaft of the motor 4, and the oil pump 3 is provided with a pump The oil inlet 31 and the pump oil outlet 32, the integrated housing 5 includes a housing 51 and a housing cavity 52 provided inside, one end of the housing 51 is connected with the body 41 of the motor 4, and the other end of the housing 51 One end is provided with a signal interface 53, a high-voltage power supply interface 54, and a low-voltage power supply interface 55, and a low-voltage controller 7 is arranged in the shell cavity 52; After the high-voltage external connection line 541 and the high-voltage controller 6 are electrically connected to the high-voltage power supply 8, the low-voltage motor rotor 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com