Variable stiffness device controlled by piezoelectric ceramics and its control method

A technology of piezoelectric ceramics and stiffness, which is applied in the direction of program-controlled manipulators, manufacturing tools, manipulators, etc., can solve the problems of large-scale commercialization, change of stiffness, and inability to realize intelligence, etc., and achieve large stiffness adjustment range, coarse stiffness, The effect of precise and controllable stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the features and advantages of this patent more obvious and easy to understand, the following specific examples are given together with the accompanying drawings and described in detail as follows:

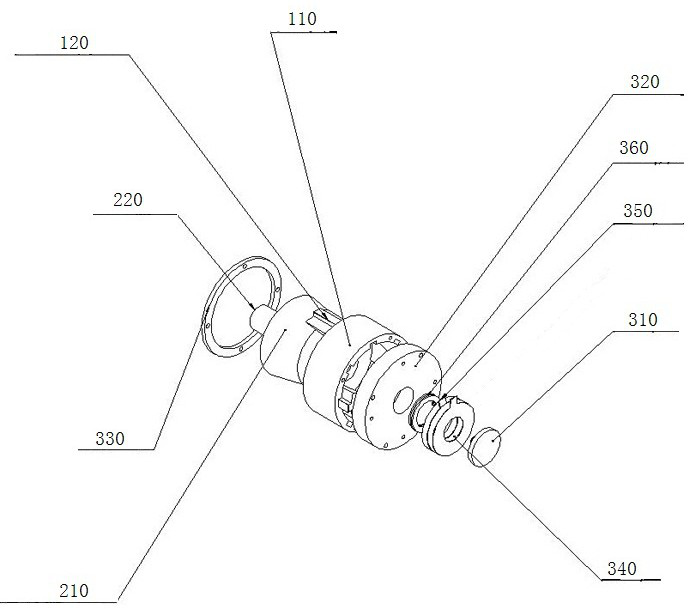

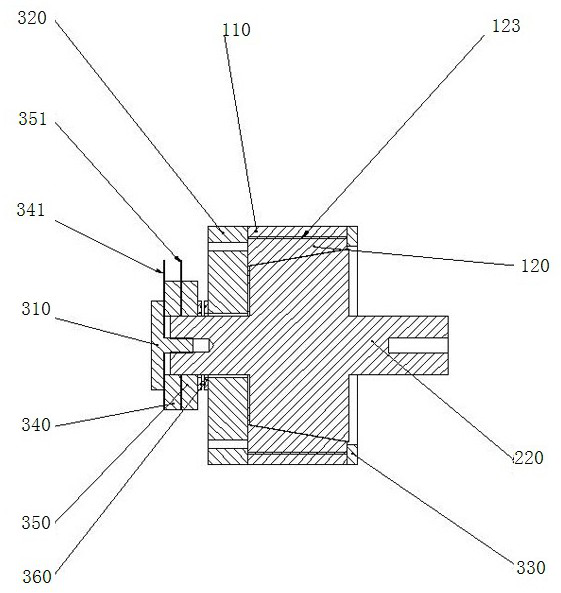

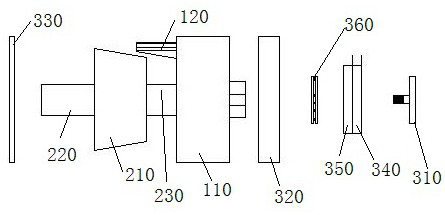

[0045] Such as Figure 1-Figure 14 As shown, the device in this embodiment mainly includes: a torque speed input part and a torque speed output part.

[0046] Wherein, the torque speed input part includes a cylindrical ring 110 with 8 spline grooves 111 on the inner wall and 8 fine-tuning blocks 120 . Such as Figure 11 , Figure 12 As shown, the eight spline grooves 111 are symmetrically distributed in pairs. In the solution provided by this embodiment, the length of the key is 50mm, the width is 10mm, and the distance from the bottom to the center of the circle is 55mm. Such as Figure 13 , Figure 14 As shown, the fine-tuning block 120 includes an upper flat key 122 (or a key close to the shape of the flat key 122) and a lower contact portion 121, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com