Method of manufacturing motor rotor and motor rotor

A technology of a motor rotor and a manufacturing method, which is applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as poor production efficiency, and achieve the effect of improving low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

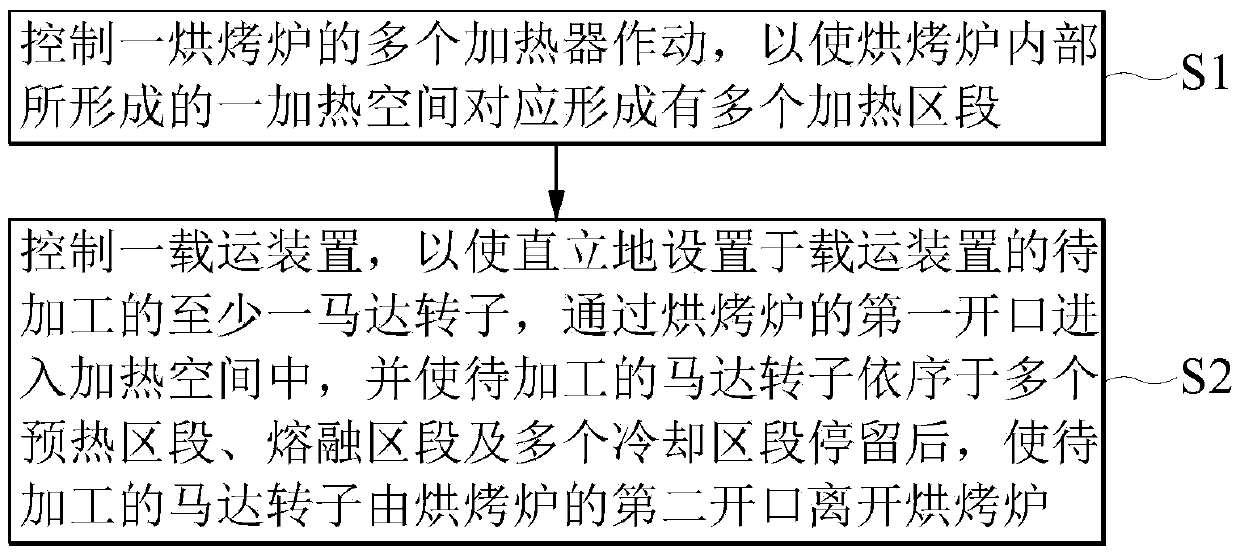

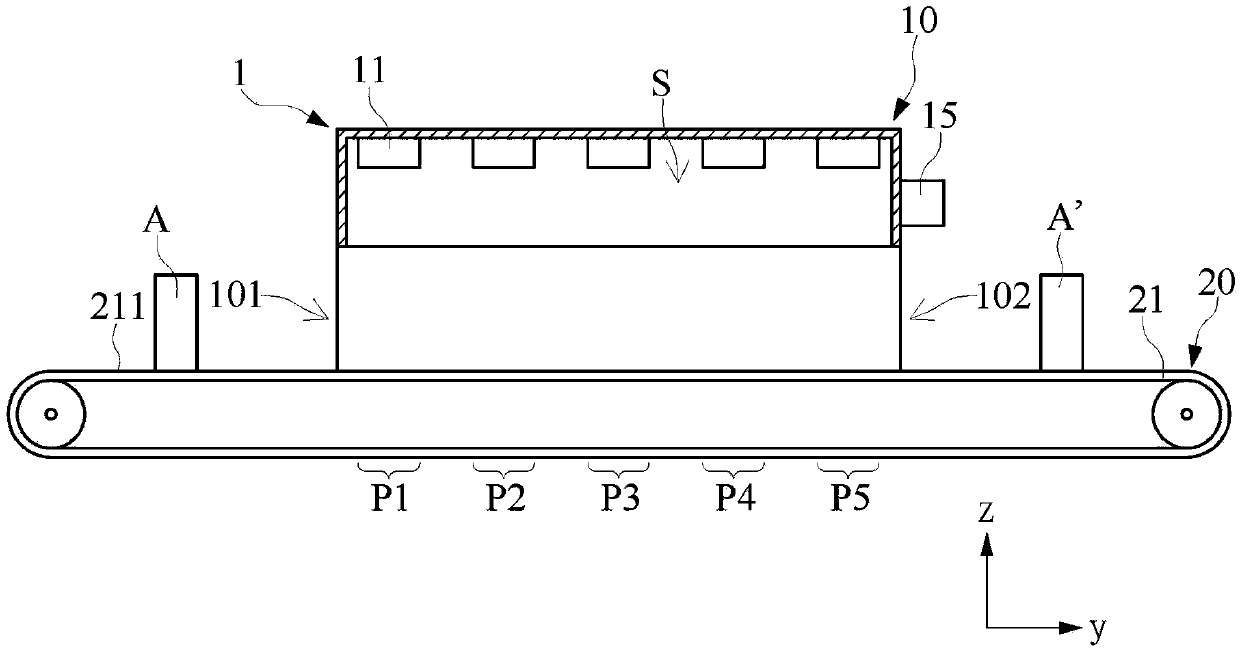

[0030] Please also refer to figure 1 and figure 2 , figure 1 It is a schematic flow chart of the manufacturing method of the motor rotor of the present invention, figure 2 It is a schematic diagram of the baking furnace mentioned in the manufacturing method of the motor rotor of this invention. Such as figure 1 As shown, the manufacturing method of the motor rotor of the present invention comprises the following steps:

[0031] A preparatory step S1: controlling the operation of multiple heaters of a baking oven, so that a heating space formed inside the baking oven is correspondingly formed with a plurality of heating zones.

[0032] A heating step S2: controlling a carrying device so that at least one motor rotor to be processed vertically arranged on the carrying device enters the heating space through the first opening of the oven, and makes the motor rotor to be processed sequentially After staying in a preheating section, a melting section and a plurality of cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com