A visual detection method for bobbin positioning of cheese

A technology for visual inspection and package yarn, which is used in measuring devices, mapping and navigation, and measuring inclination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

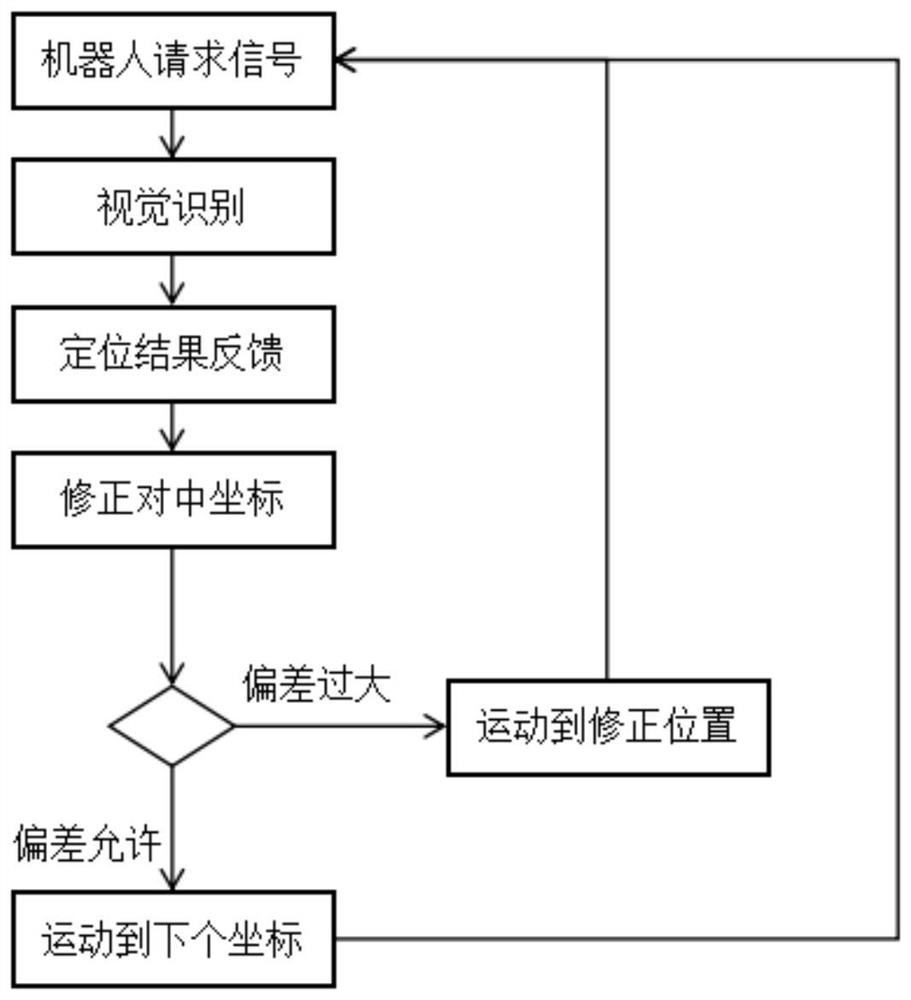

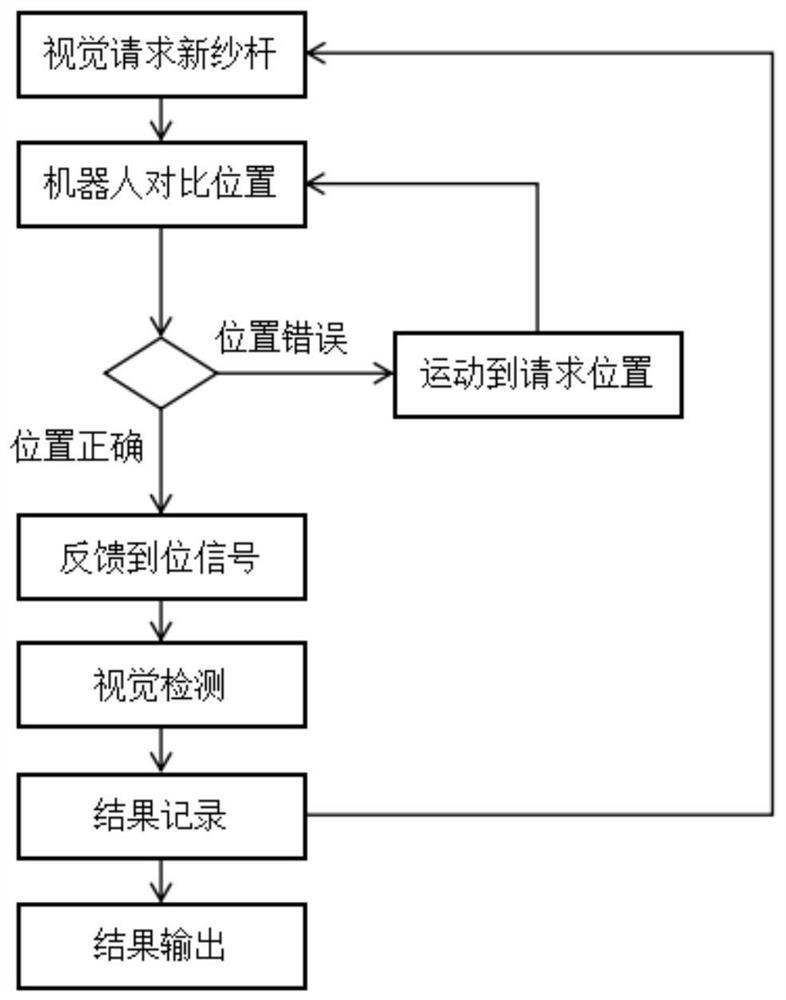

[0017] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0018] The present invention provides a method for visual detection of the positioning of the yarn rods of the package yarn. The single rod mode is adopted, that is, the 120 rods of the whole yarn cage are detected one by one. Because the length of the yarn rod is about 2m, by adjusting the field of view and focal length of the camera, the reflection effect of the background chassis can be reduced, the background can be blurred and darkened, and the effect of the yarn rod head can be highlighted. Through the illumination of the ring LED light source, the brightness of the top of the yarn rod is increased to maximize the exposure, and the background interference is also darkened, making the detection more accurate.

[0019] The method includes the following steps:

[0020] 1) Set up a visual inspection system, the system includes a vision system and a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com