Detection table, detection workpiece and three-coordinate measuring machine

A technology for testing tables and workpieces, applied in the direction of measuring devices, instruments, etc., can solve the problems of inconvenient positioning and fixing, and achieve the effect of being convenient for later use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

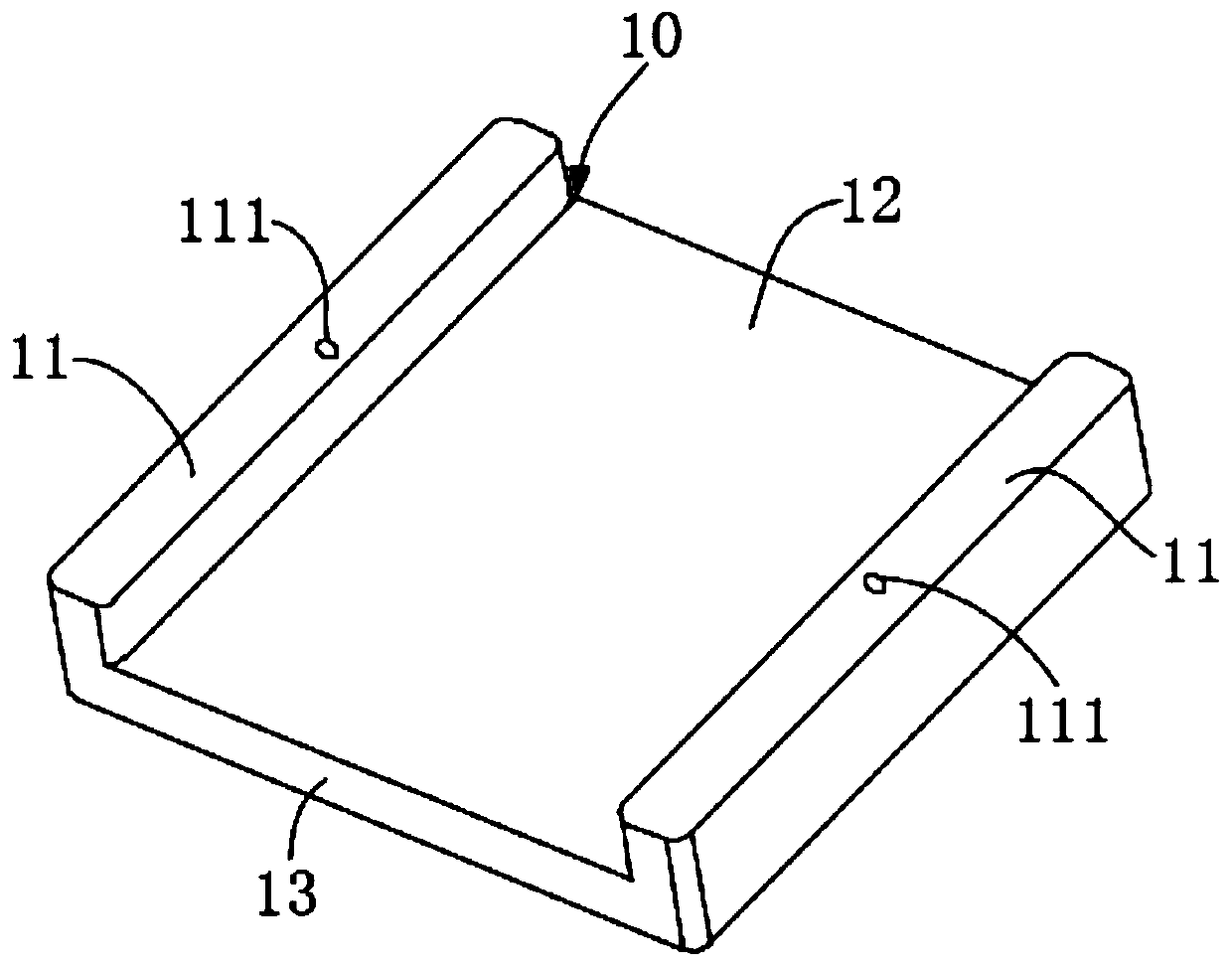

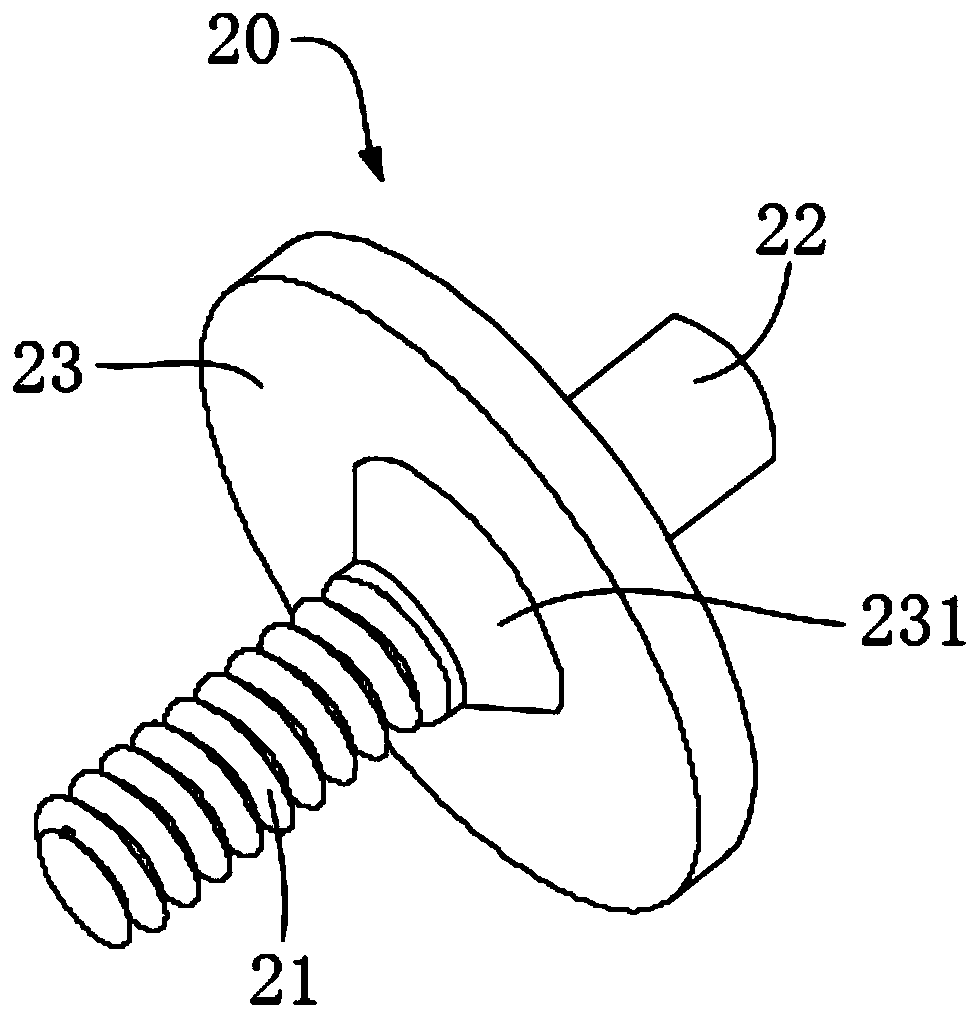

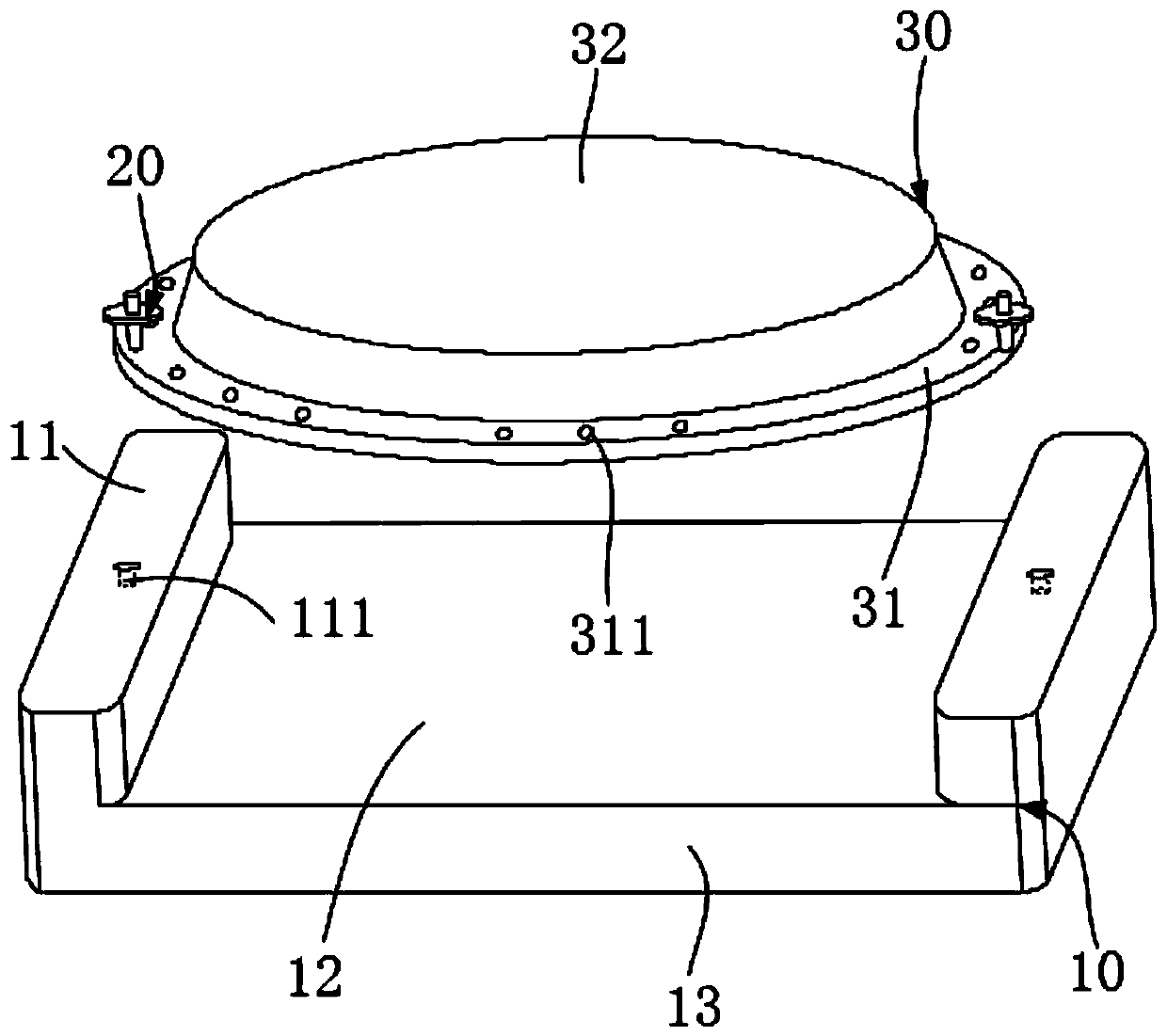

[0039] like Figure 1-Figure 5 As shown, the detection platform provided in this embodiment includes a workbench 10 and a positioning column 20, the worktable 10 is provided with a plurality of positioning holes 111, the number of positioning columns 20 is multiple, and at least two positioning columns 20 can pass through the workpiece. The different mounting holes 311 are inserted into the corresponding positioning holes 111, and the positioning column 20 can be detachably connected with the workpiece.

[0040] like Figure 3-Figure 5 As shown, the detection workpiece provided in this embodiment is detected by the above-mentioned detection platform, including a workpiece body 30; the workpiece body 30 has a mounting portion 31 arranged around the workpiece body 30, and the mounting portion 31 is provided with a plurality of mounting holes 311, The positioning post 20 is plugged into the positioning hole 111 through the mounting hole 311 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com