Annular monorail mobile laser coal inventory device for closed coal yard

A laser disk and mobile technology, which is applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of increased coal error, low positioning accuracy, and high cost of coal, and meet the requirements of reducing the scanning range and enhancing anti-interference ability, the effect of reducing procurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings.

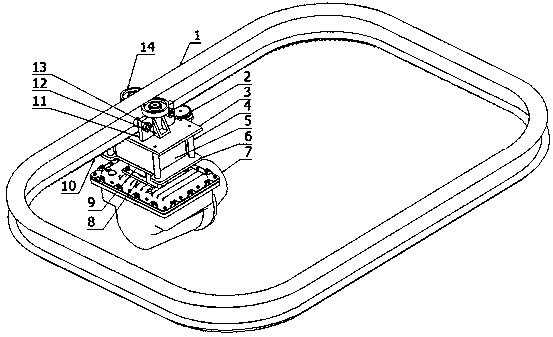

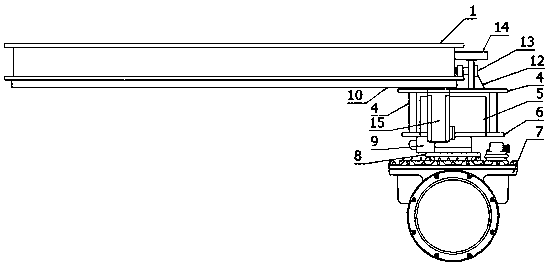

[0018] Such as figure 1 , figure 2 shown.

[0019]A circular monorail mobile laser coal pan device in a closed coal yard is characterized in that: the closed coal yard circular monorail mobile laser coal pan device is composed of a circular track, a drive positioning device, a coal pan device and a drive control system 5, and the circular track consists of Segmented I-shaped steel track 1 and transmission rack 10 are formed. A single I-shaped steel track 1 and transmission rack 10 have the same length. The length of the straight line section and the turning radius of the circular track are determined according to the size of the closed coal yard and the scanning range. , each section of I-steel track 1 is hoisted and fixed on the row frame of the closed coal yard ceiling in sequence along the direction of the coal pan, and the tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com