Pipeline type constant-temperature evaporator for refrigeration house

A constant temperature evaporation and evaporator technology, applied in evaporators/condensers, applications, refrigerators, etc., can solve the problems of inability to accurately control temperature and temperature fluctuations, and achieve the effect of stable temperature and accurate temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

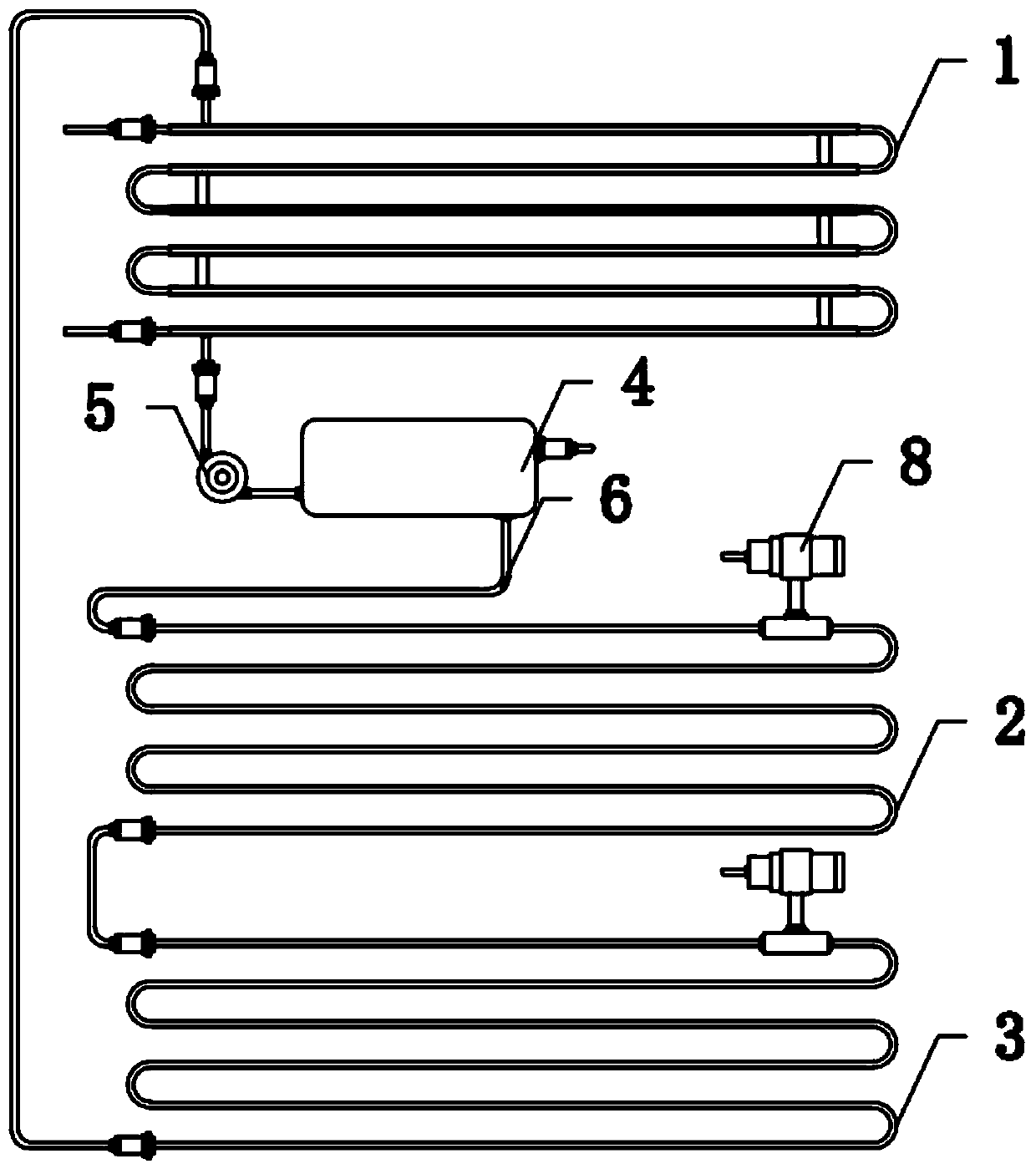

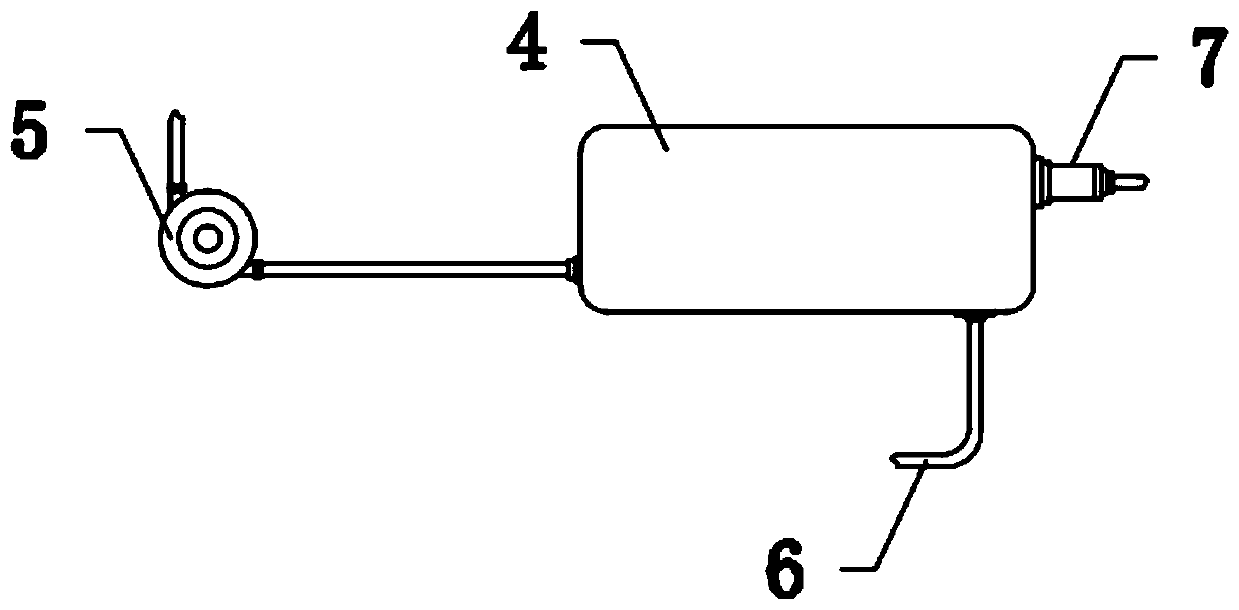

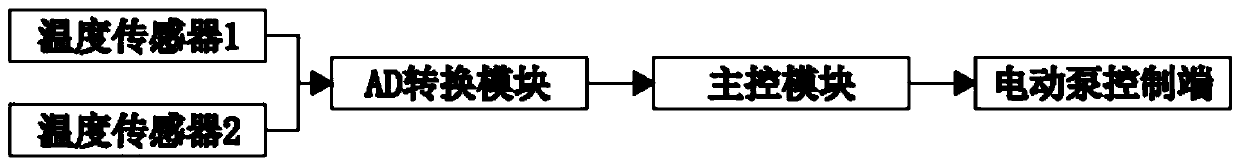

[0027] see Figure 1-4 , the present invention provides a technical solution: a pipe-type constant temperature evaporator for cold storage, including an upper row pipe 1 of the evaporator, a middle row pipe 2 of the evaporator, a lower row pipe 3 of the evaporator and a constant temperature pool 4, and an upper row pipe of the evaporator 1. The middle row pipe 2 of the evaporator and the lower row pipe 3 of the evaporator are arranged and installed sequentially from top to bottom. Pipe 2 and evaporator lower pipe 3 are successively installed on the cold storage wall divided into thirds. The outer wall of the evaporator upper pipe 1 is covered with a heat exchange jacket, and the lower left outlet of the heat exchange jacket is connected to the electric drive pump 5 The liquid inlet of the evaporator is connected to the liquid inlet, and the low-temperature condensed liquid in the upper exhaust pipe 1 of the evaporator performs heat exchange with the cooling liquid in the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com