Nested continuous water boiler liner structure

A continuous and nested technology, applied in the direction of water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of complex pipeline structure, inability to provide continuous boiling water output, heat loss of boiling water, etc., and achieve simplified internal The structure of the gallbladder, the effect of delaying the uncontrolled temperature rise process and improving the safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

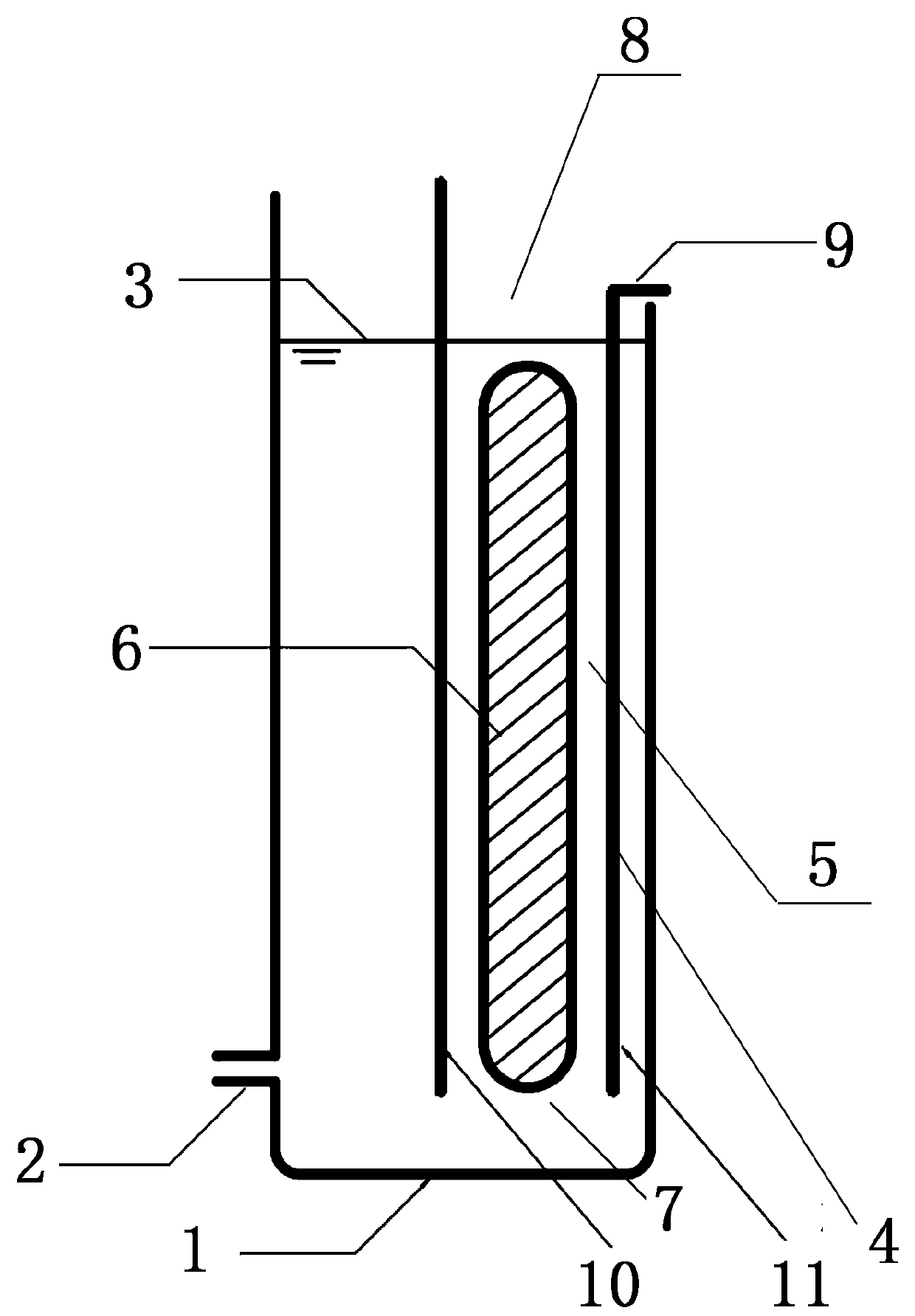

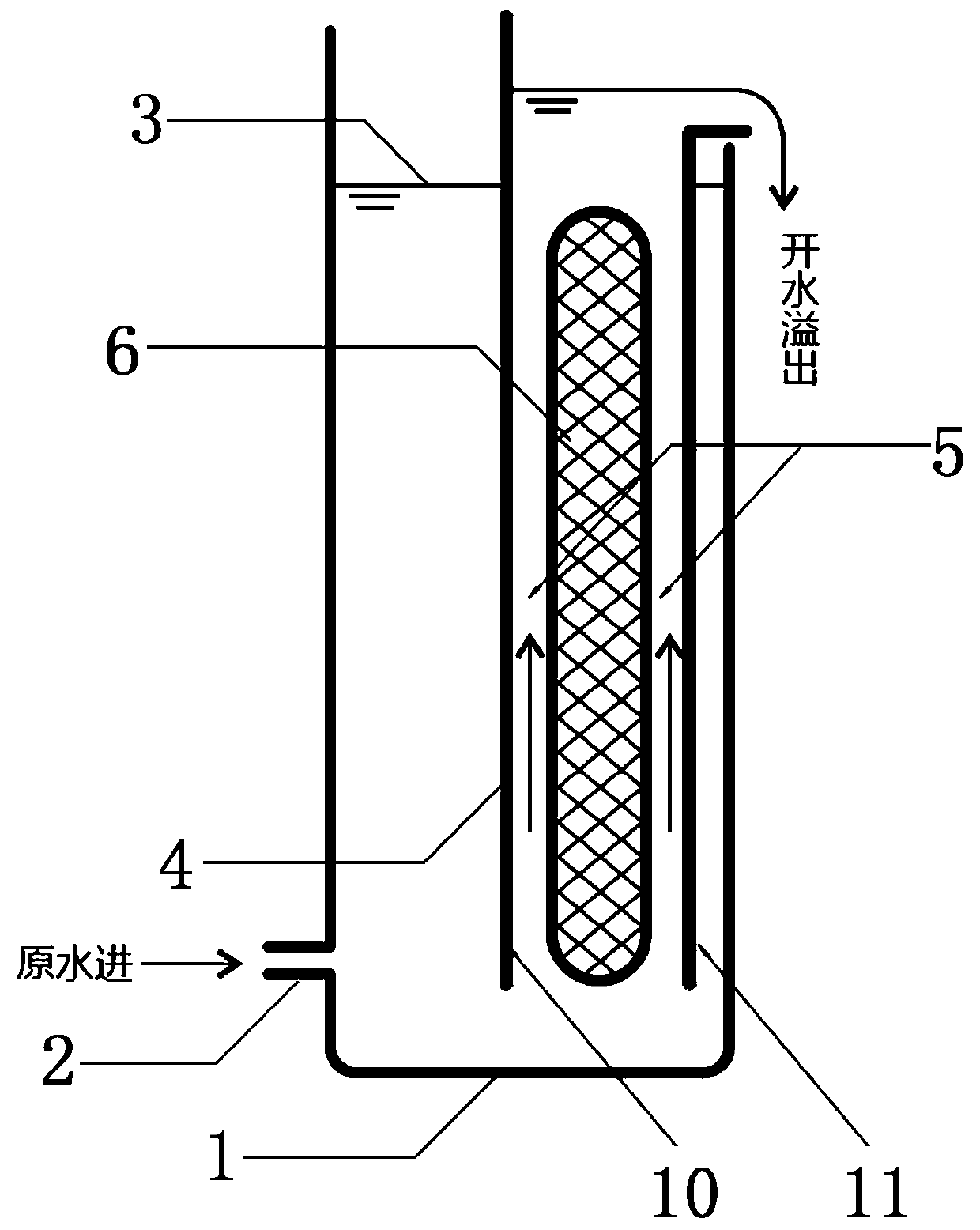

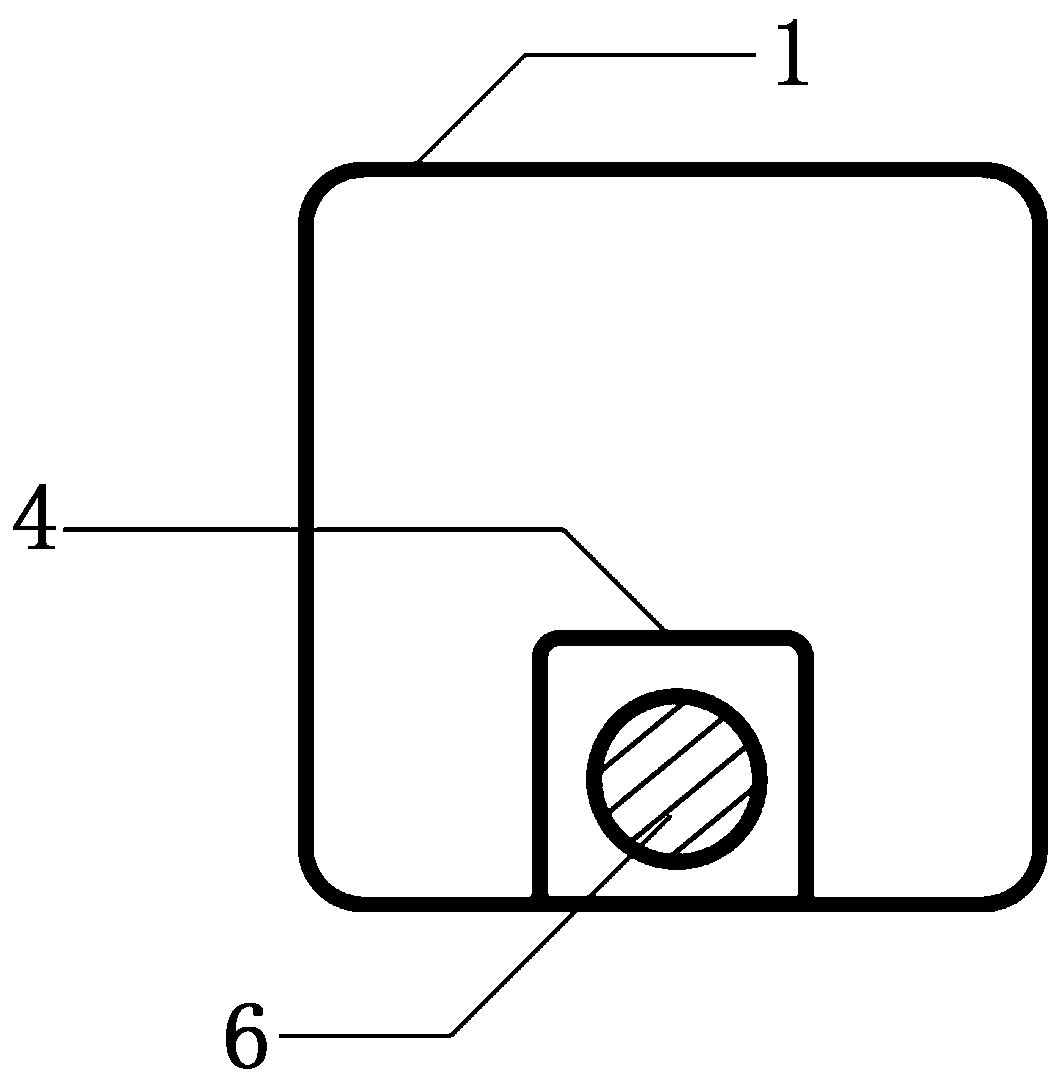

[0012] The present invention will be further described below with reference to the accompanying drawings.

[0013] The invention discloses a nested continuous water boiler inner container structure, which is different from the prior art in that: it includes an inner container shell 1, and the inner container shell 1 is provided with a water inlet port 2 near the bottom, and the inner container shell 1 There is a raw water level 3 inside, the raw water enters the inner tank shell 1 from the water inlet 2, and the raw water is controlled at the above raw water level 3, and at least one heating tube shell 4 is also arranged in the inner tank shell 1 to heat A heating lumen 5 is formed in the tube shell 4, and a heating body 6 is arranged inside the heating lumen 5. The bottom of the heating tube shell 4 is provided with a water inlet opening 7, and the heating tube shell 4 connects with the inner tank shell through the opening 7 at the bottom. The inner cavity of the body 1 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com