Movable reinforcement machining shed structure

A steel structure and processing shed technology, applied in industrial buildings, building structures, buildings, etc., can solve the problems of being blown by the wind, the length of the steel bar processing shed is not easy to be too long, and it is not conducive to the promotion and use of the steel bar processing shed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

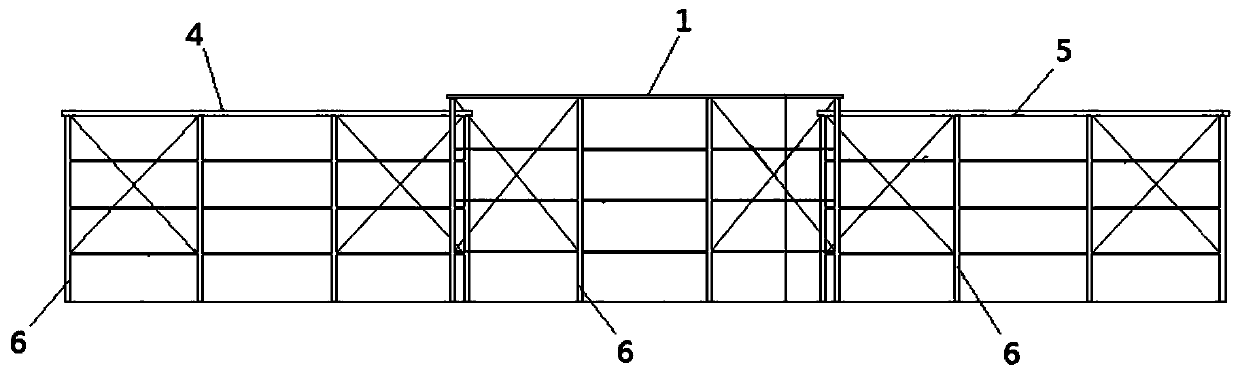

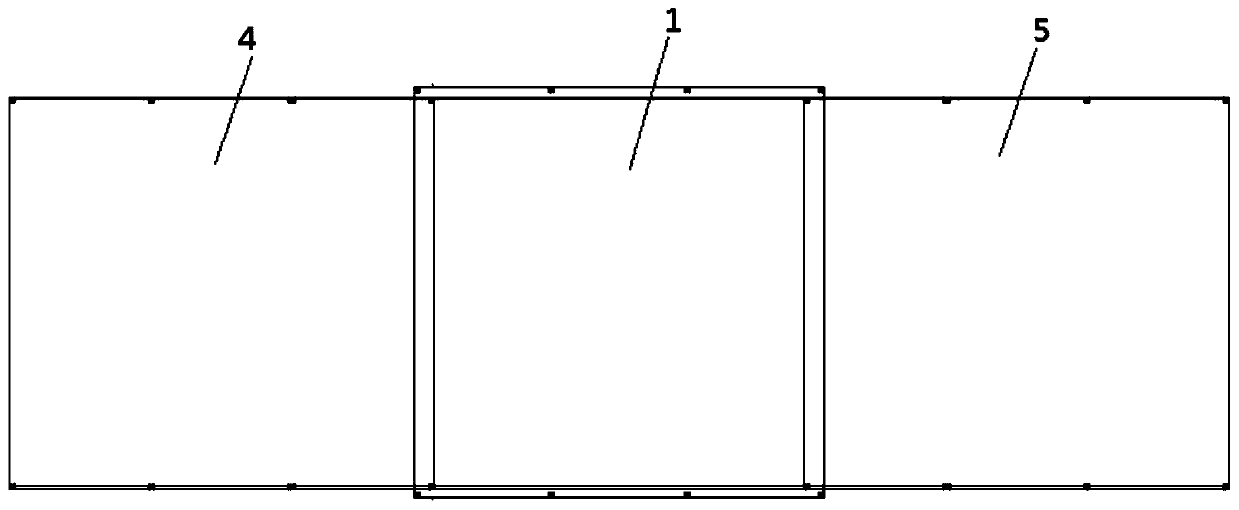

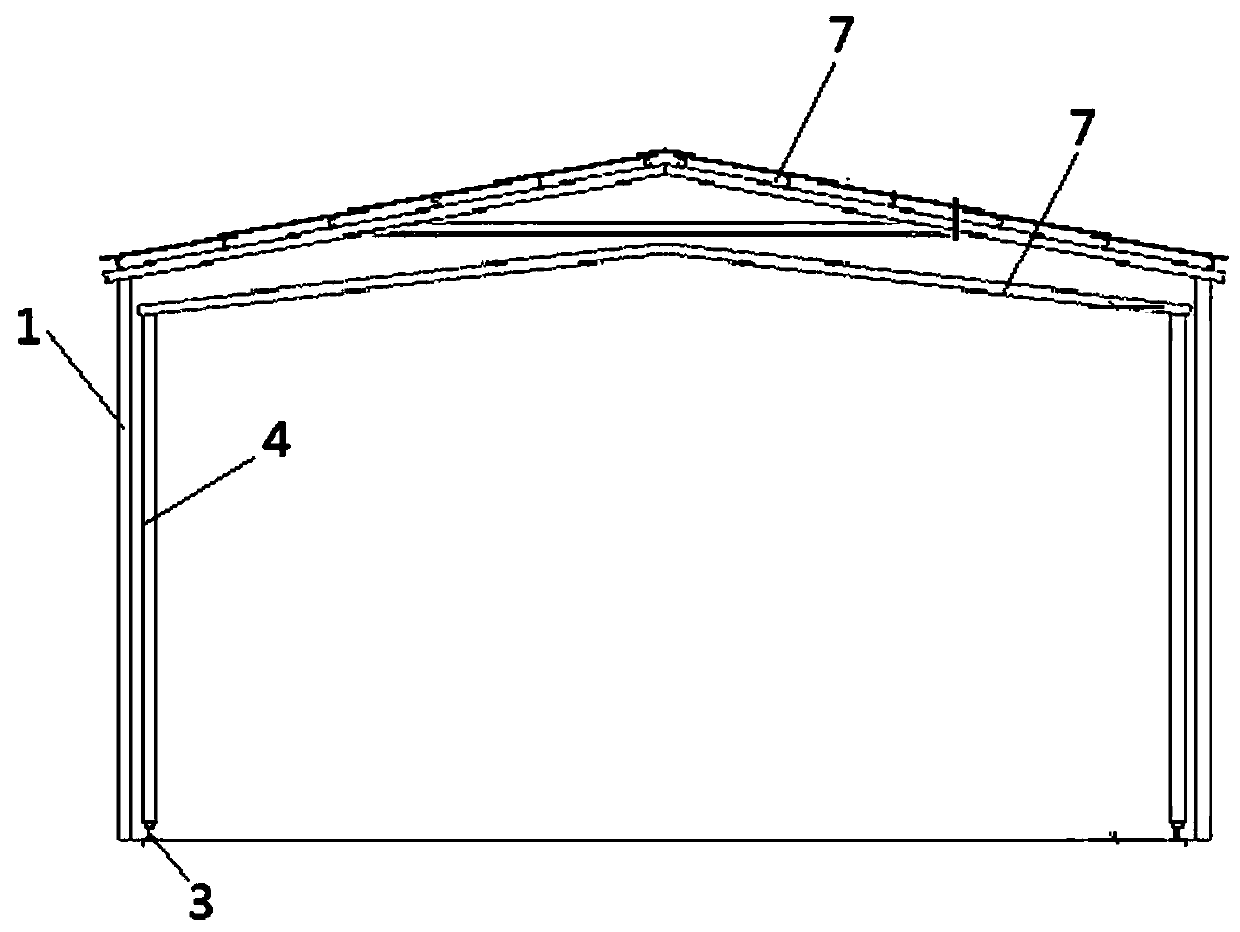

[0038] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , is a movable steel bar processing shed structure provided by the embodiment of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the structure includes a first steel structure shed main body 1, the first steel structure shed main body 1 is fixedly installed on the upper part of the hardened foundation 2; at least one gable end of the first steel structure shed main body 1 is missing to form an open structure; The above hardened foundation is made of C25 concrete.

[0039] A slide rail assembly, the slide rail assembly includes two parallel and separated slide rails 3 located on the upper part of the hardened foundation, and each end of the two slide rails 3 extends to the first steel rail through the open structure Inside the main body 1 of the structural shed; the two ends of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com