Intelligent automatic basket charging device for fungus bags

An automatic and intelligent technology, applied in packaging, transportation and packaging, conveyor objects, etc., can solve the problems of micro-holes, inaccurate bacterial bag grasping, inaccurate positioning, etc., to prevent micro-holes and avoid infection of miscellaneous bacteria. , The effect of stable operation and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

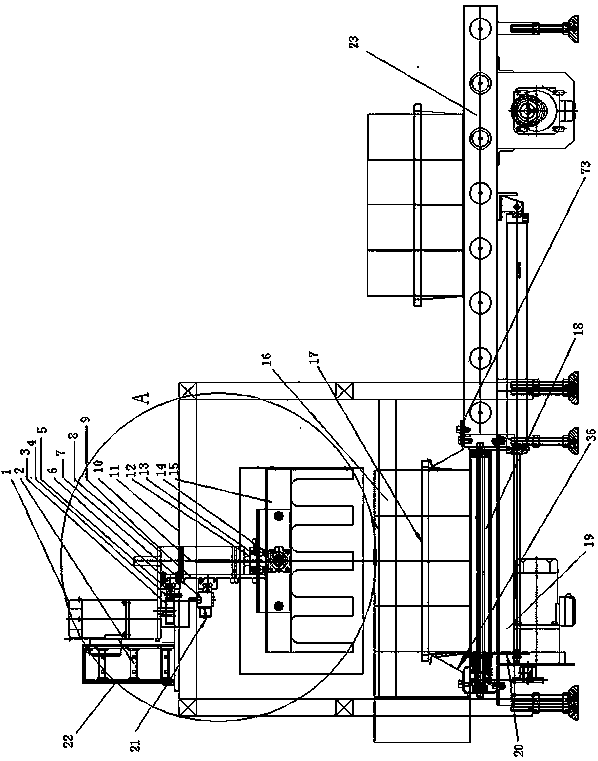

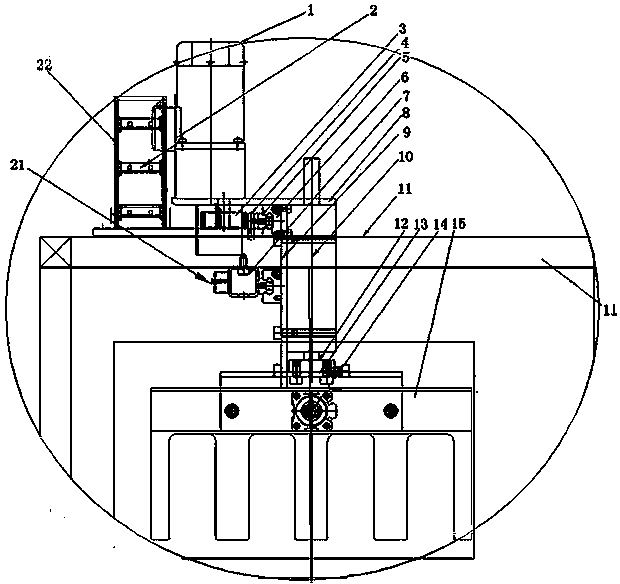

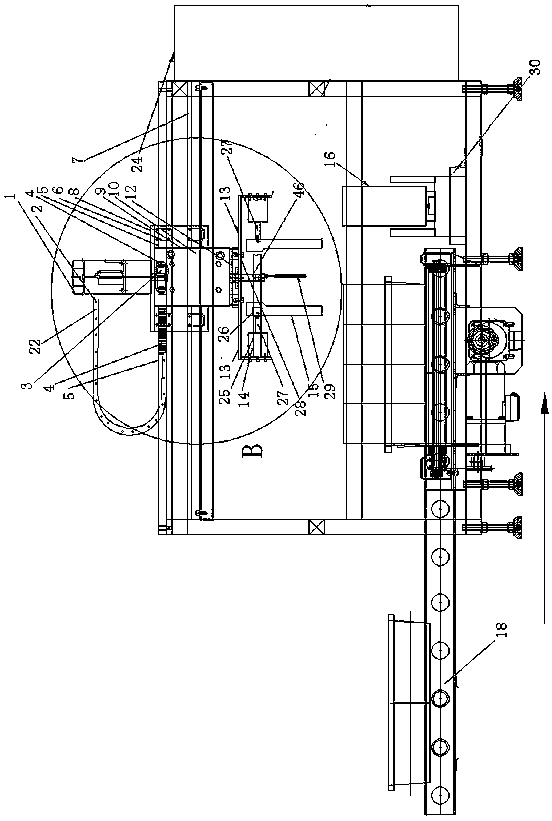

[0045] The structure of the intelligent automatic bacteria packaging basket device of the present invention is as follows Figure 1-5 As shown, it includes a control system 24, a transmission system, a rail mechanism, a gripping mechanism, and a bagging mechanism.

[0046] The specific structure is as follows: the upper part of the bracket 11 is installed with two linear guides 5 up and down in parallel, the rear side of the upper linear guide 5 is installed with a linear gear 4, a horizontal base plate 8 is arranged above the bracket 11, and a motor 1 is installed on the horizontal base plate 8, and the motor 1 passes through the drag chain 22 is connected to the control system 24; the motor shaft 56 of the motor 1 penetrates the lower part of the horizontal base plate 8 to install the motor gear 3, which meshes and installs with the linear gear 4; the front side of the horizontal base plate 8 is vertically provided with a vertical base plate 9 and the vertical base plate 9 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com