Welding device for roller cover and connecting shaft of corn thresher and operation steps

A welding device and roller cover technology, applied in tin feeding devices, auxiliary devices, welding equipment, etc., can solve the problems of low efficiency, increased bending stress, and high noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

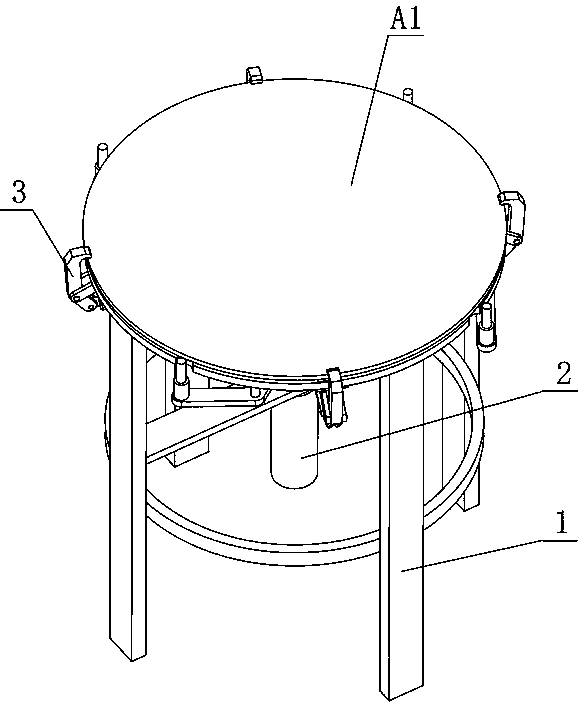

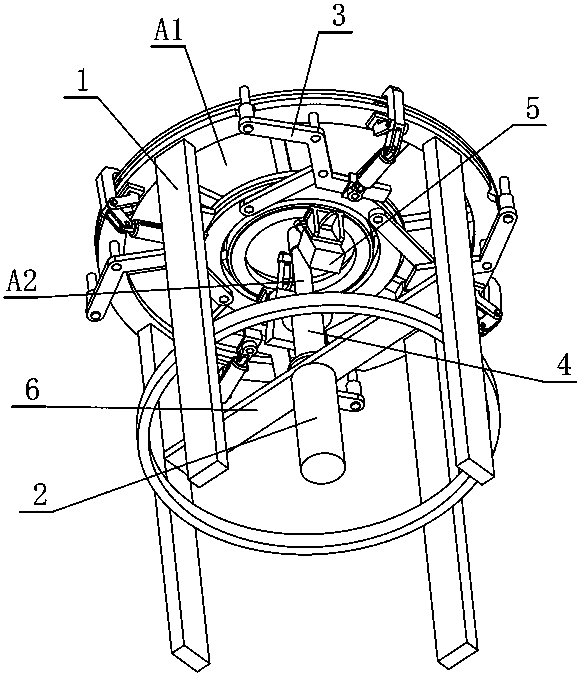

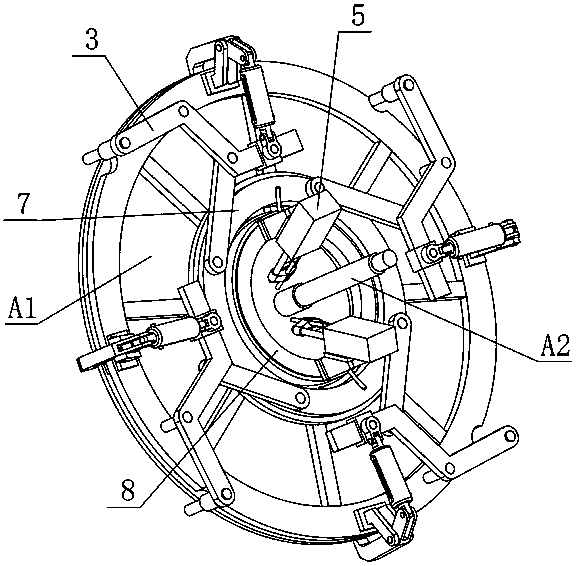

[0043] combine Figures 1 to 11 , a welding device for a drum cover and a connecting shaft of a corn thresher of the present invention includes a welding base 1, a clamping cylinder 2, a synchronous centering and fixing mechanism 3, a centering sleeve 4, a welding mechanism 5, and a supporting beam 6 , outer turntable 7, inner turntable 8, the synchronous centering and fixing mechanism 3 includes a column pin 1 301, a connecting rod 302, a centering pin 303, a swing rod 304, a column pin 2 305, a pressing rod 306, and a pressing rod bracket 307, column pin three 308, column pin four 309, column pin five 310, elastic link 311, column pin six 312, connecting block 313, column pin seven 314, slider 315, the welding mechanism 5 includes welding cylinder frame 501. The welding gun cylinder 502, the welding gun fixing frame 503, and the welding gun 504 are defined as the inner side toward the center axis of the drum cover A1, and the outer side otherwise, for the purpose of describi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com