Filter core structure

A filter element and filter material technology, applied in water/sludge/sewage treatment, reverse osmosis, membrane, etc., can solve problems such as TDS exceeding the standard, achieve good versatility and ensure the health of drinking water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solution, purpose and advantages of the present invention clearer, the present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

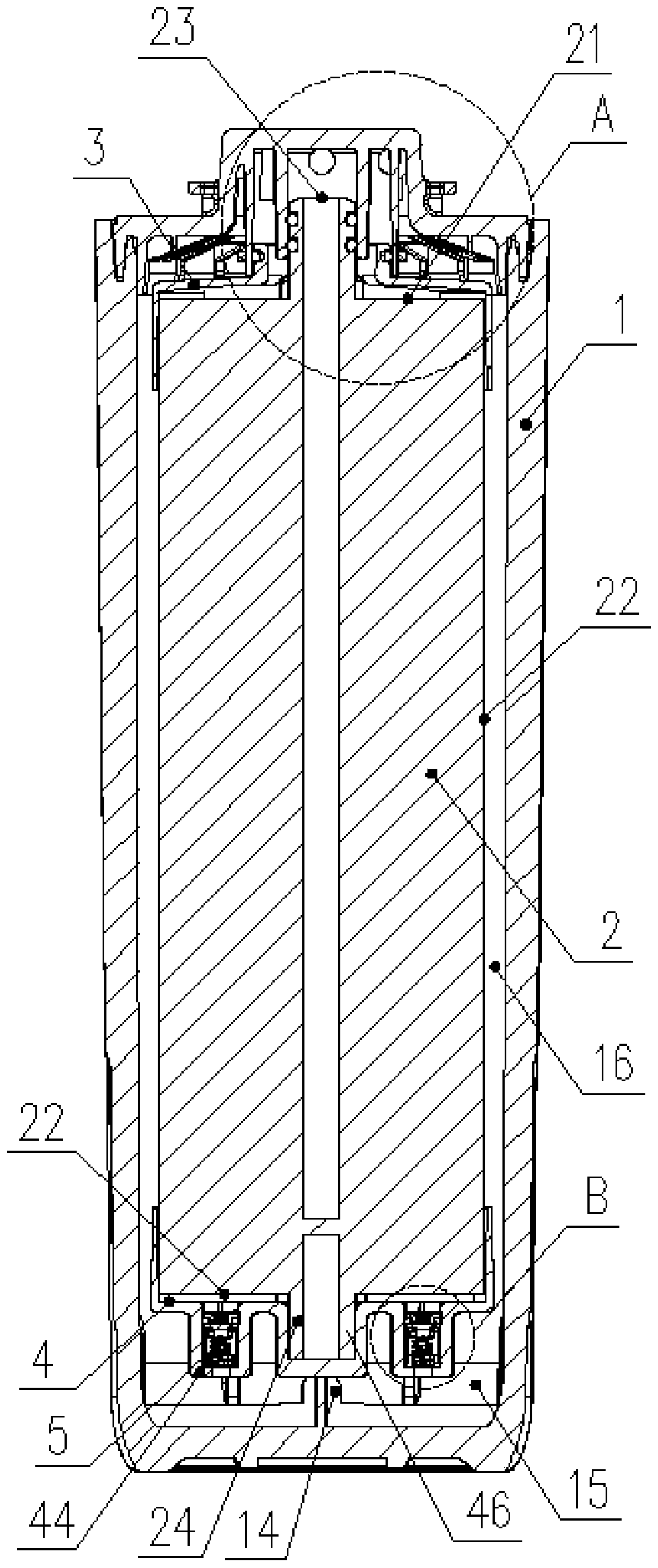

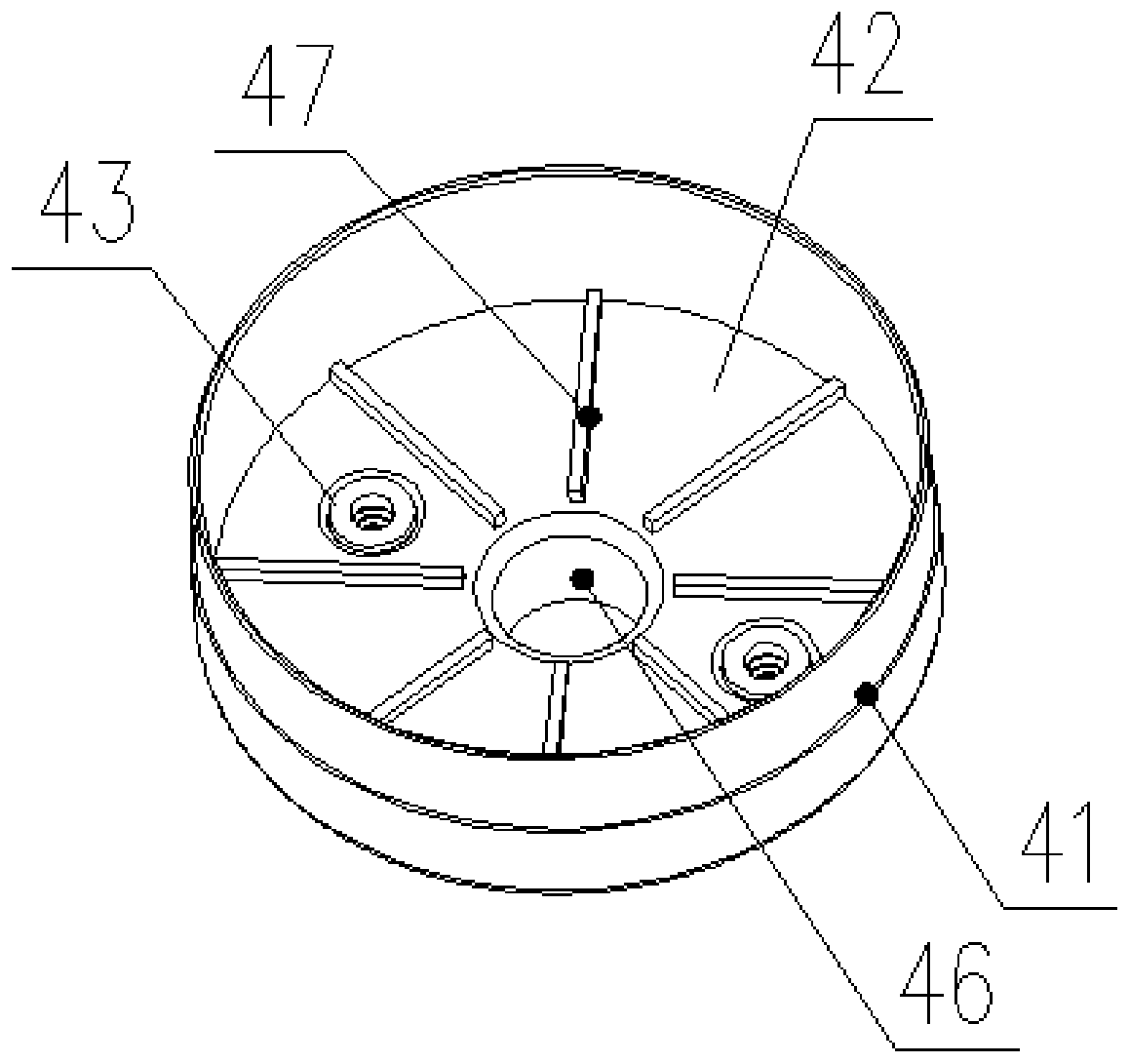

[0031] Such as Figures 1 to 4 Shown, a kind of filtering assembly of the present invention comprises:

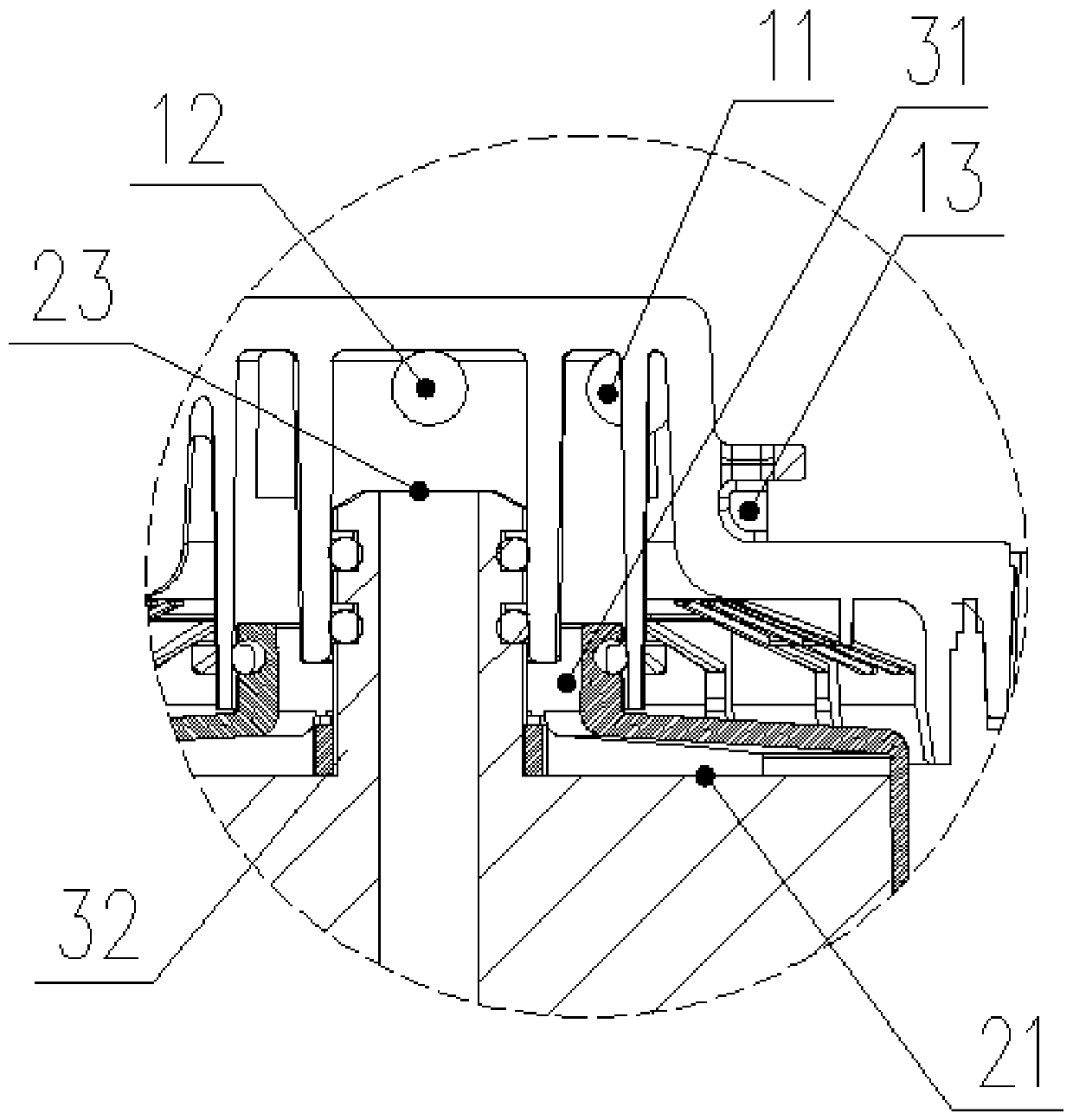

[0032] The filter material module 2 is set and applied as an RO membrane structure, its raw water input port 21 is set at the top side, its waste water output port 22 is set at the bottom side and the outer peripheral side, and its inner side is the pure water side where pure water is generated, The pure water side is extended with a central pipe and guided to the top side of the filter module 2 to form a pure water output port 23 for the pure water output;

[0033] Water port connection seat 3, which is arranged on the top side of the filter material module 2; the water port connection seat 3 is provided with a raw water inlet 31 corresponding to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com