link chain

A technology of link chains and inner link plates, which is applied in the field of link chains, can solve the problems of material selection or size design structural space restrictions and restrictions, and achieve the effect of optimizing axial fixation and enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

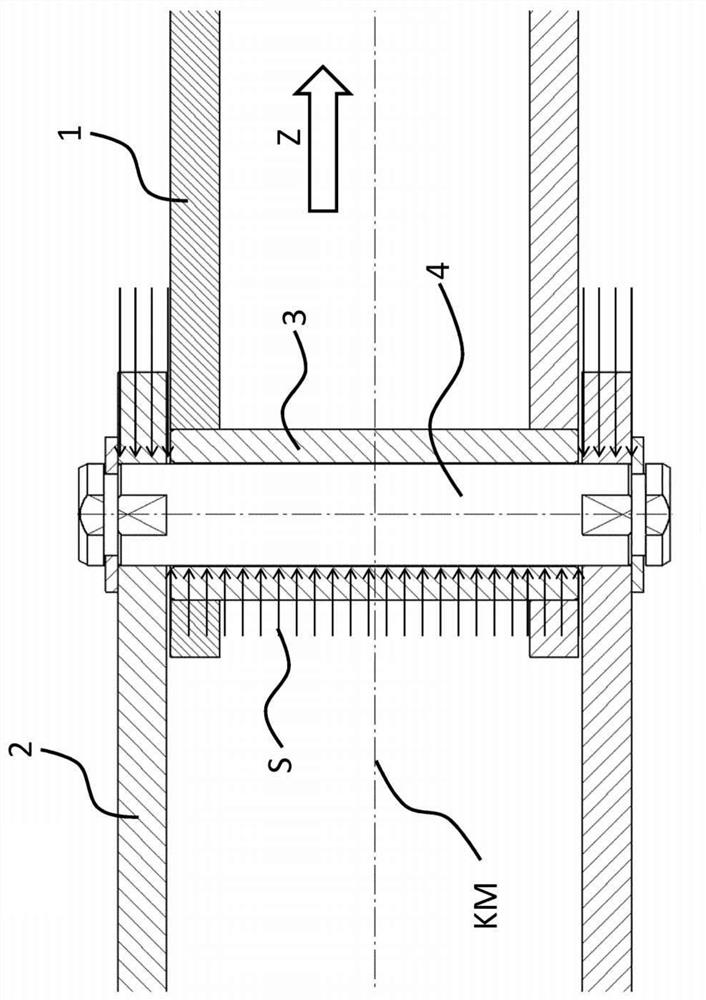

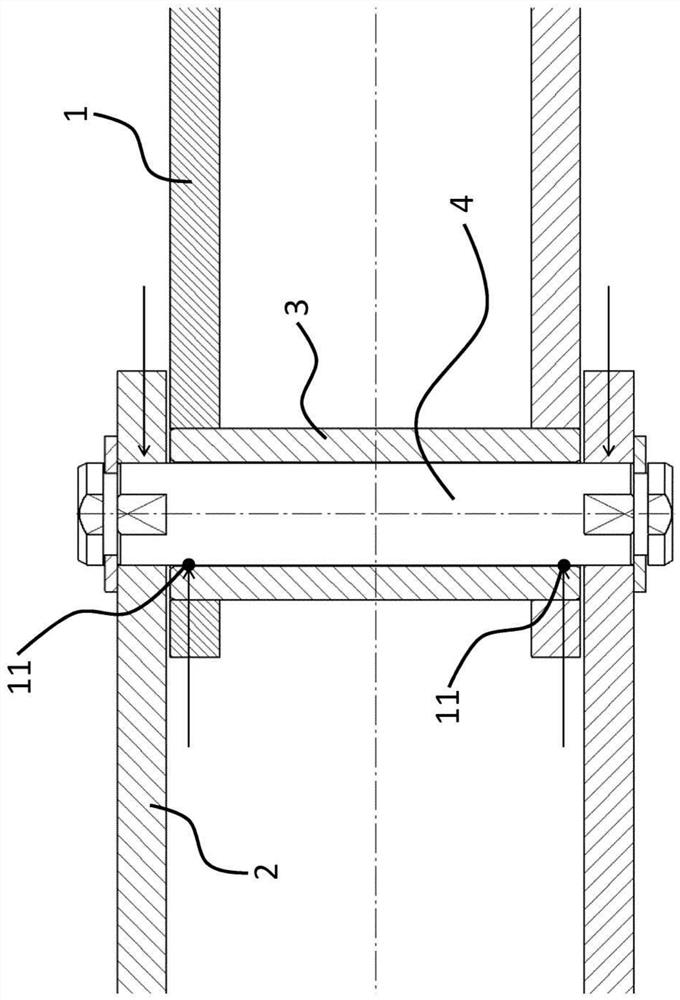

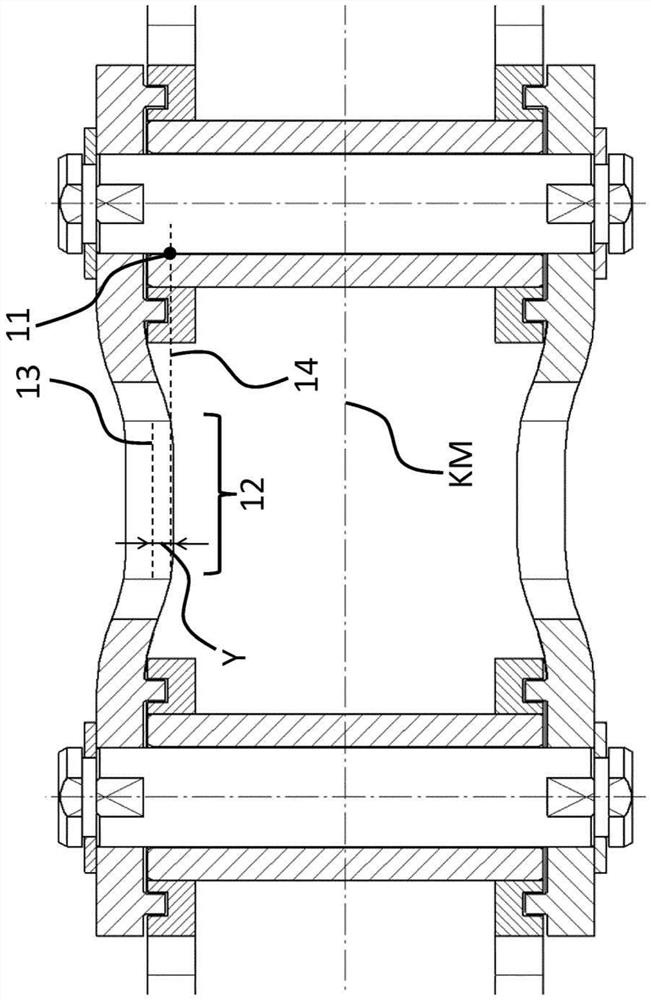

[0050] The following reference numbers are used in the figures:

[0051] 1 Internal connection board

[0052] 2 External connection board

[0053] 3 Sleeves

[0054] 4 pins

[0055] 5 holes

[0056] KM Chain Centerline / Chain Centerline

[0057] L Longitudinal axis of connecting plate / Longitudinal line of connecting plate

[0058] LM connecting plate center line / connecting plate center line

[0059] LMQ connecting plate central axis cross section

[0060] Center point of hole B

[0061] BM Hole Centerline / Hole Centerline

[0062] BMQ hole wall cross section

[0063] 11 Points of force transmission

[0064] 12 Sections of the outer connecting plate

[0065] 13 Section Centerlines

[0066] 14 Line through point 11

[0067] Y distance between chain centerline and offset centerline

[0068] Z pull direction

[0069] S Uniform load

[0070] 21 Waist in

[0071] 22 Areas removed

[0072] 31 Reinforced areas / reinforcements / thickenings

[0073] 41 Boss / Ring

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com