Novel connector assembly for preventing plug terminal from swinging and anti-swinging method thereof

A technology of connector assembly and plug connector, which is applied in the parts, connection, connection/disconnection of connecting device, etc., can solve the problem of easy swinging of plug terminals, so as to provide assembly comfort and optimize the overall use space. , The effect of simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

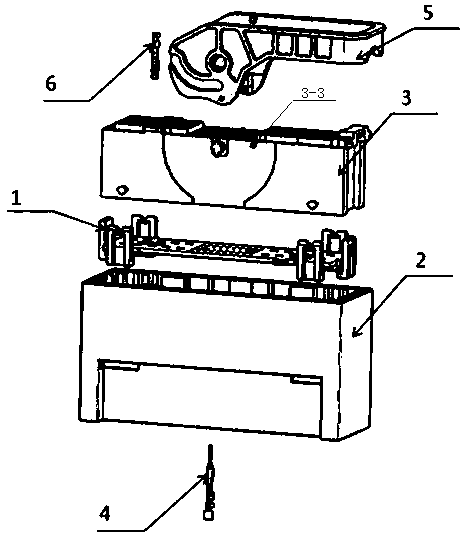

[0035] Example 1, such as figure 1 As shown, a new connector assembly for preventing the swing of the plug terminal includes a plug connector 2, a movable card board 1, a socket connector 3 and a booster lever 5. In the mated state, the movable card board 1 is located inside the plug connector 2 and Clamping with plug connector 2 for easy disassembly and assembly; socket connector 3 is located inside plug connector 2 and clamped with movable card board 1. The outer ring of the socket connector is slightly smaller than the size of the outer ring of the movable card board. The socket connector It can be buckled inside the plug connector and clamped with the movable card board. The booster lever 5 is hinged on the socket connector 3 and is movably connected with the plug connector 2. The rotation of the booster lever drives the relative movement of the socket connector, the movable card board and the plug connector to realize the connection between the socket connector and the plug...

Embodiment 2

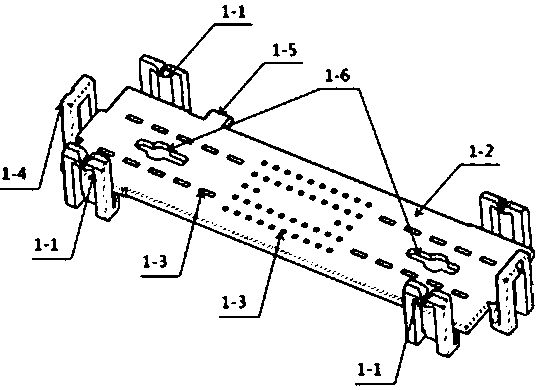

[0038] Example 2, such as Figure 4 with 5 As shown, a new connector assembly for preventing the swing of the plug terminal. The plug connector 2 includes a plug connection housing 2-7. The plug connection housing 2-7 is provided with a first plug-in board 2-8. A plug-in board 2-8 is fixedly connected to the plug connection housing. The first plug-in board 2-8 is provided with plug terminal mounting holes 2-6, and the plug terminal 4 is inserted into the plug terminal mounting holes 2-6 and The swing holes 1-3 are matched to stabilize the plug terminals. The upper part of the first plug-in board 2-8 is fixedly provided with a guide post 2-4 or the guide post is integrally connected with the first plug-in board. The guide posts 2-4 correspond to the guide holes 1-6. During installation, the movable card board is sleeved on the guide post through the guide hole to play the role of positioning the movable card board. The inner wall at both ends of the plug connection housing 2-7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com