Building construction quality actual measurement data acquisition device

A technology for data acquisition and construction, applied in measuring devices, optical devices, measuring instruments, etc., can solve problems such as heavy workload, inability to move freely, and difficulty in measuring the size of the entire surface hole, achieve high-precision measurement, reduce artificial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

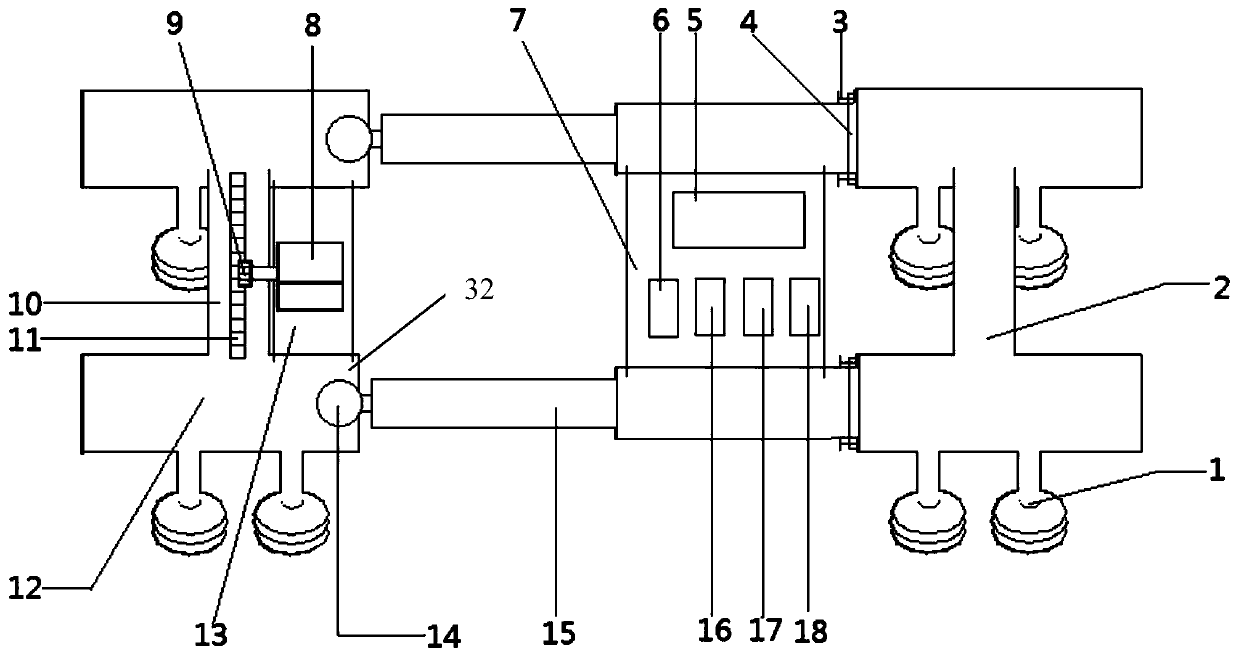

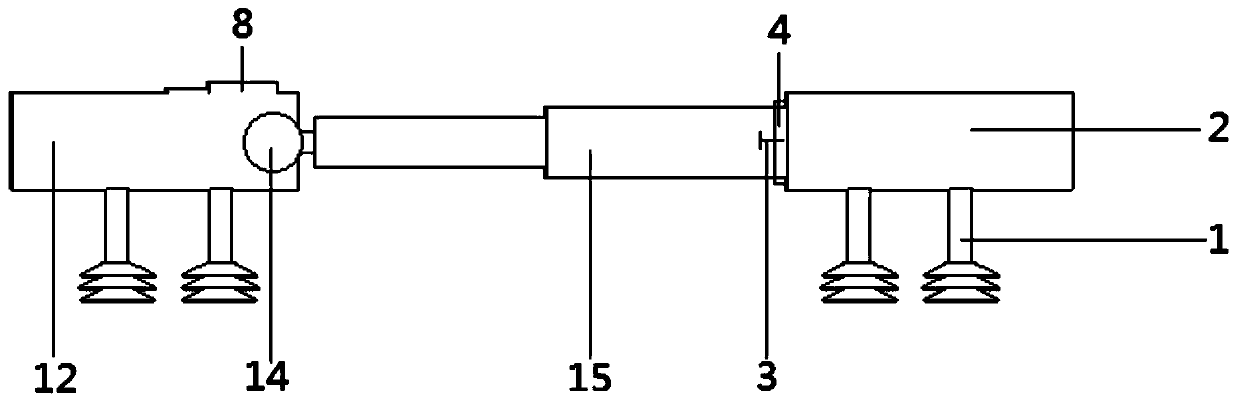

[0025] The technical solution and working principle of the present invention will be described in detail below in conjunction with the drawings and embodiments.

[0026] Such as Figure 1-Figure 9 As shown, the building construction quality actual measurement data acquisition device provided by the present invention includes a car body, a control mechanism and a data acquisition mechanism; wherein, the car body includes a rear suction cup group 2, a rear frame base 7, a steering gear 8, Gear 9, rack 11, front suction cup group 12, front vehicle frame base 13, spherical hinge 14 and electric push rod 15; Wherein, described rear suction cup group 2 and front suction cup group 12 structure are identical, all comprise four vertical The suction cup assembly 1 and a horizontally arranged and I-shaped vehicle frame 32; the front and rear bottom surfaces of the side beams of the vehicle frame 32 are respectively connected to the top of a suction cup assembly 1; the rack 11 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com