Pervious concrete prepared from recycled aggregate and preparation process of pervious concrete

A technology of permeable concrete and recycled aggregate, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low strength requirements, affecting the use range of recycled permeable concrete, and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

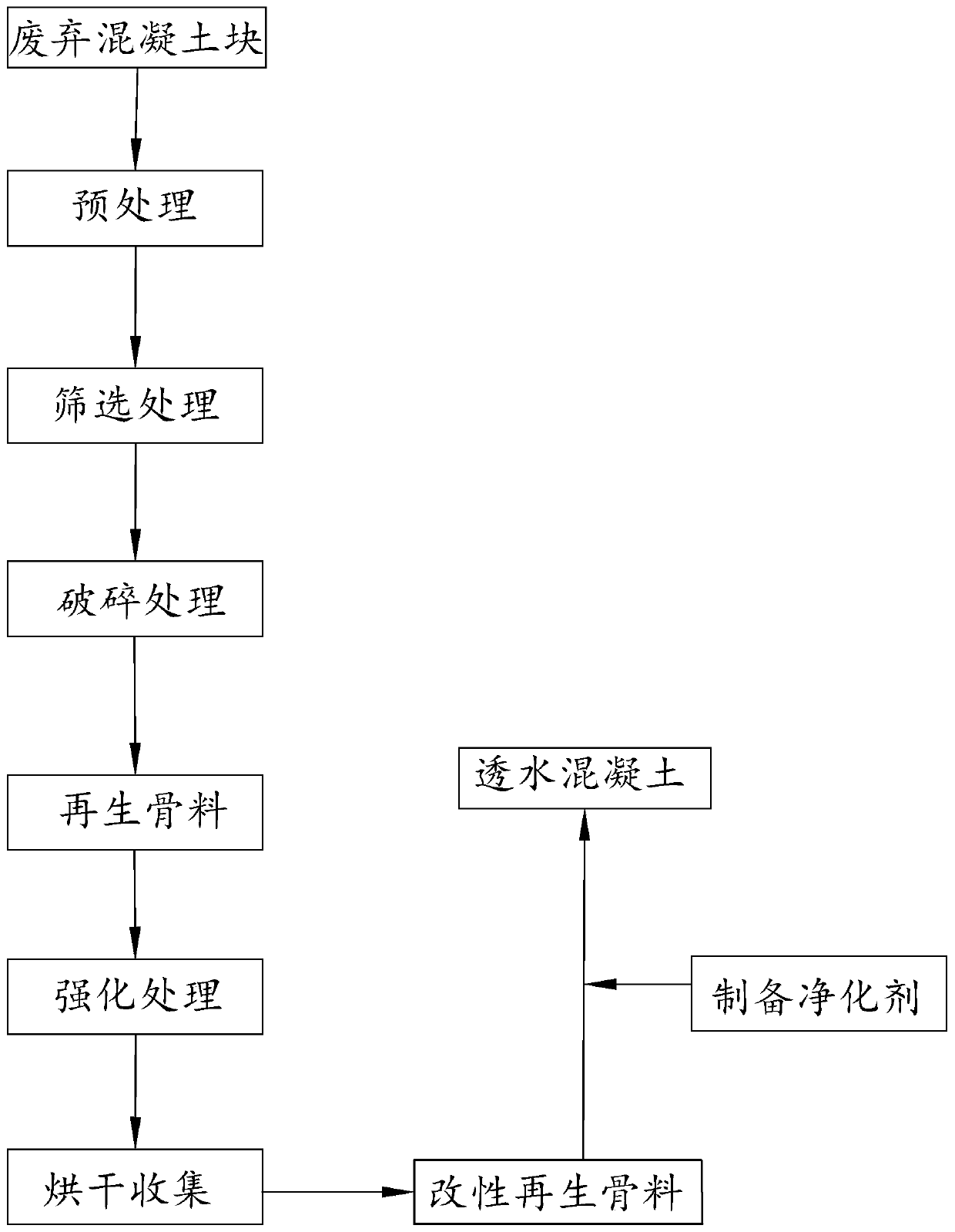

[0096] refer to figure 1 , which is a preparation process of permeable concrete prepared from recycled aggregate disclosed by the present invention, which includes the following preparation process:

[0097] 1) Preparation of purifying agent: after mixing 18% nano-titanium dioxide, 16% silver phosphate, 8% nano-zinc oxide, 3% sodium tripolyphosphate, 8% chitosan and 25% water, add 22% calcined hydrotalcite, soaked for 2 hours under vacuum pressure; after soaking, the calcined hydrotalcite was taken out, and then the calcined hydrotalcite was dried at 25°C to obtain a purifying agent;

[0098] The particle size of calcined hydrotalcite is 1-3mm;

[0099] Preparation of modified recycled aggregate:

[0100] S1: Pretreatment: Hammer the waste concrete blocks so that the diameter of the hammered concrete blocks is less than 50mm, and carry out moisture spraying treatment and epidemic prevention treatment on the waste concrete blocks;

[0101] S2: screening treatment: perform sc...

Embodiment 1

[0124] The difference between Embodiment 10-13 and Embodiment 1 is that the nutrient solution comprises the following raw materials in weight percentage:

[0125]

[0126]

[0127] The difference between Embodiment 14-17 and Embodiment 1 is that the first auxiliary agent includes the following raw materials in weight percentage:

[0128]

[0129] The difference between Embodiment 18-21 and Embodiment 1 is that the second auxiliary agent includes the following raw materials in weight percentage:

[0130]

[0131] The difference between Embodiment 22-25 and Embodiment 1 is that the scavenger comprises the following raw materials in weight percent:

[0132]

[0133] The difference between Embodiment 26-29 and Embodiment 1 is that the fibrous filler comprises the following raw materials in weight percent:

[0134]

[0135] The difference between Embodiment 30-33 and Embodiment 1 is that all the other admixtures include the following raw materials in weight perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com