Method for treating surface of transfer printing concrete

A technology of concrete surface and treatment method, which is applied in the field of concrete decoration, can solve the problems of increasing production cost and affecting concrete performance, and achieve the effects of solving color difference, low production cost and low operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] Preparation method of transfer concrete:

[0016] Print the retarder on the base film according to the set pattern, pour concrete on the base film, uncover the base film after the concrete hardens, and wash the concrete surface with water to obtain the transferred concrete with the corresponding pattern.

[0017] Methods to prevent efflorescence on the surface of transferred concrete:

[0018] Include the following steps:

[0019] a. Vacuum drying: Put the freshly washed transfer concrete into a vacuum drying oven for vacuum drying;

[0020] b. Carbonation: Carry out surface accelerated carbonation treatment to the dry transfer concrete, and the surface accelerated carbonation condition is: CO 2 Concentration not less than 99%, CO 2 The pressure is not less than 0.2MPa; the carbonization time is 2-4h.

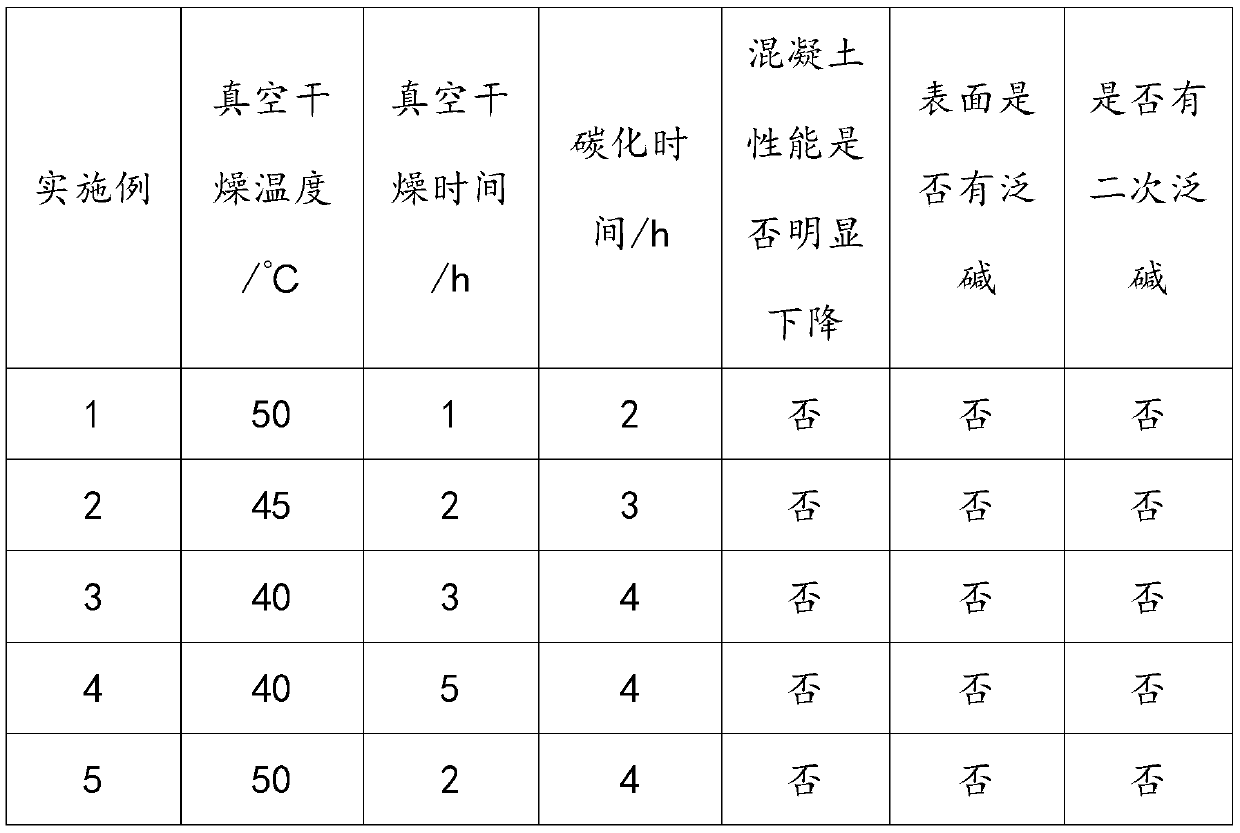

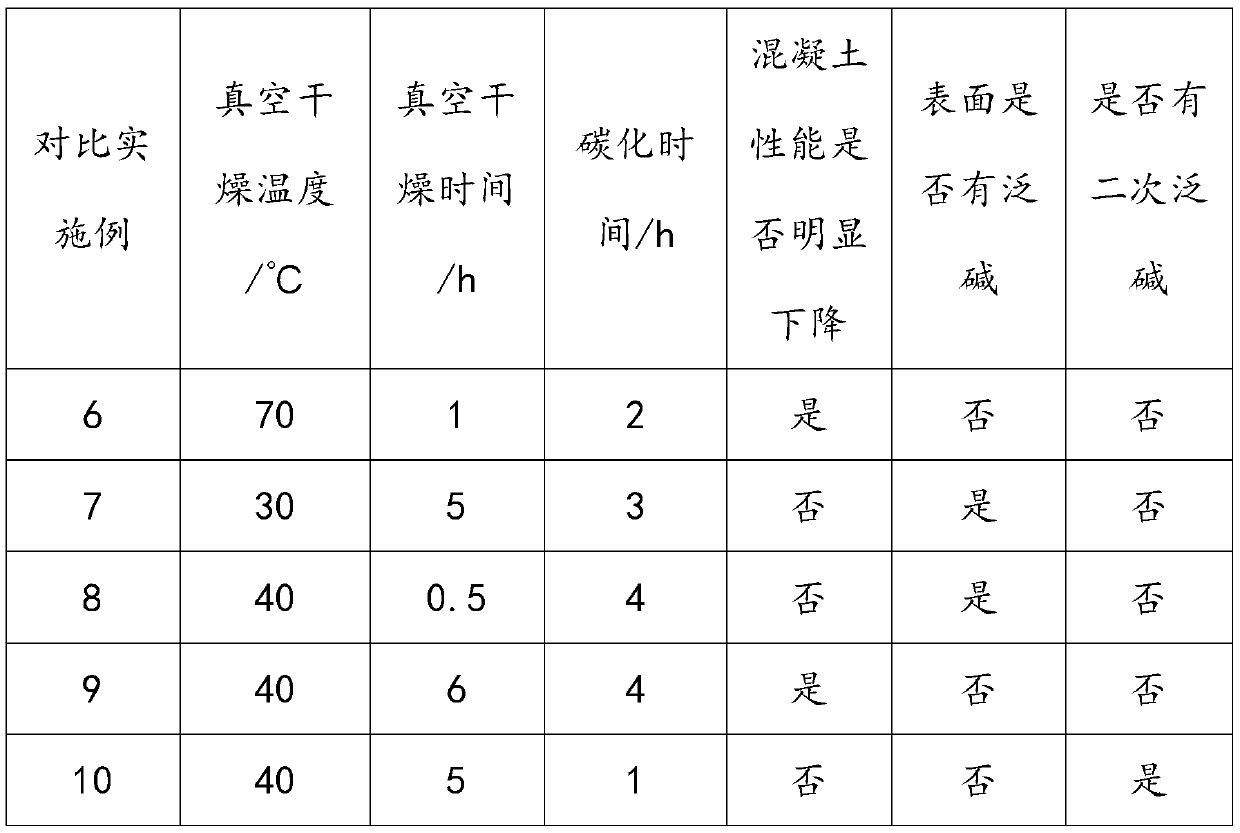

[0021] The parameters and effects of Examples 1-5 using the above method are shown in Table 1, and the parameters and effects of Comparative Examples 6-10 are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com