Efficient reaction device for preparing polycarboxylic acid

A reaction device, polycarboxylic acid technology, applied in chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, chemical instruments and methods, etc. Monitor the changes of the liquid level of the reactor and the poor accuracy of the operator's observation, so as to ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

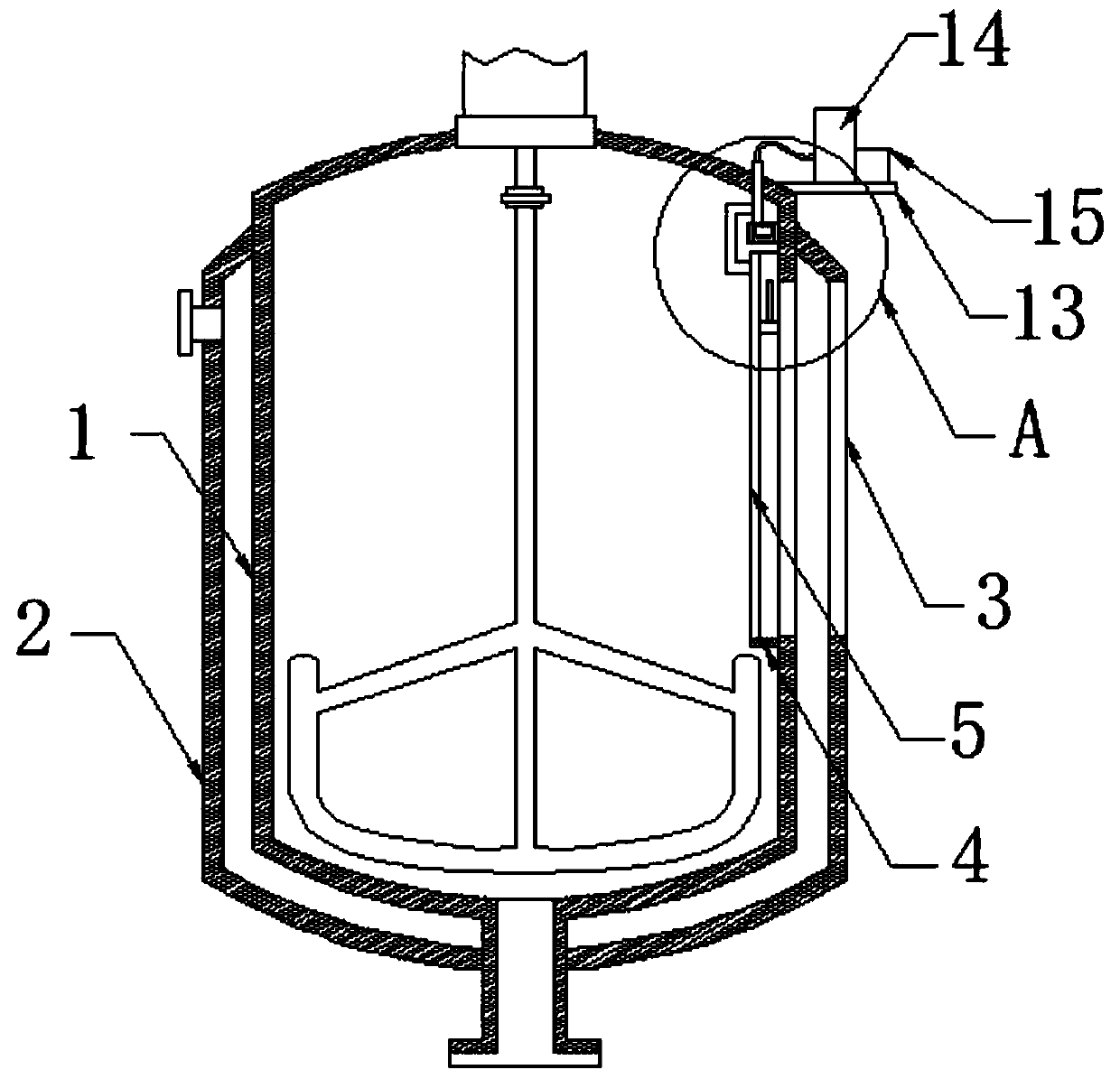

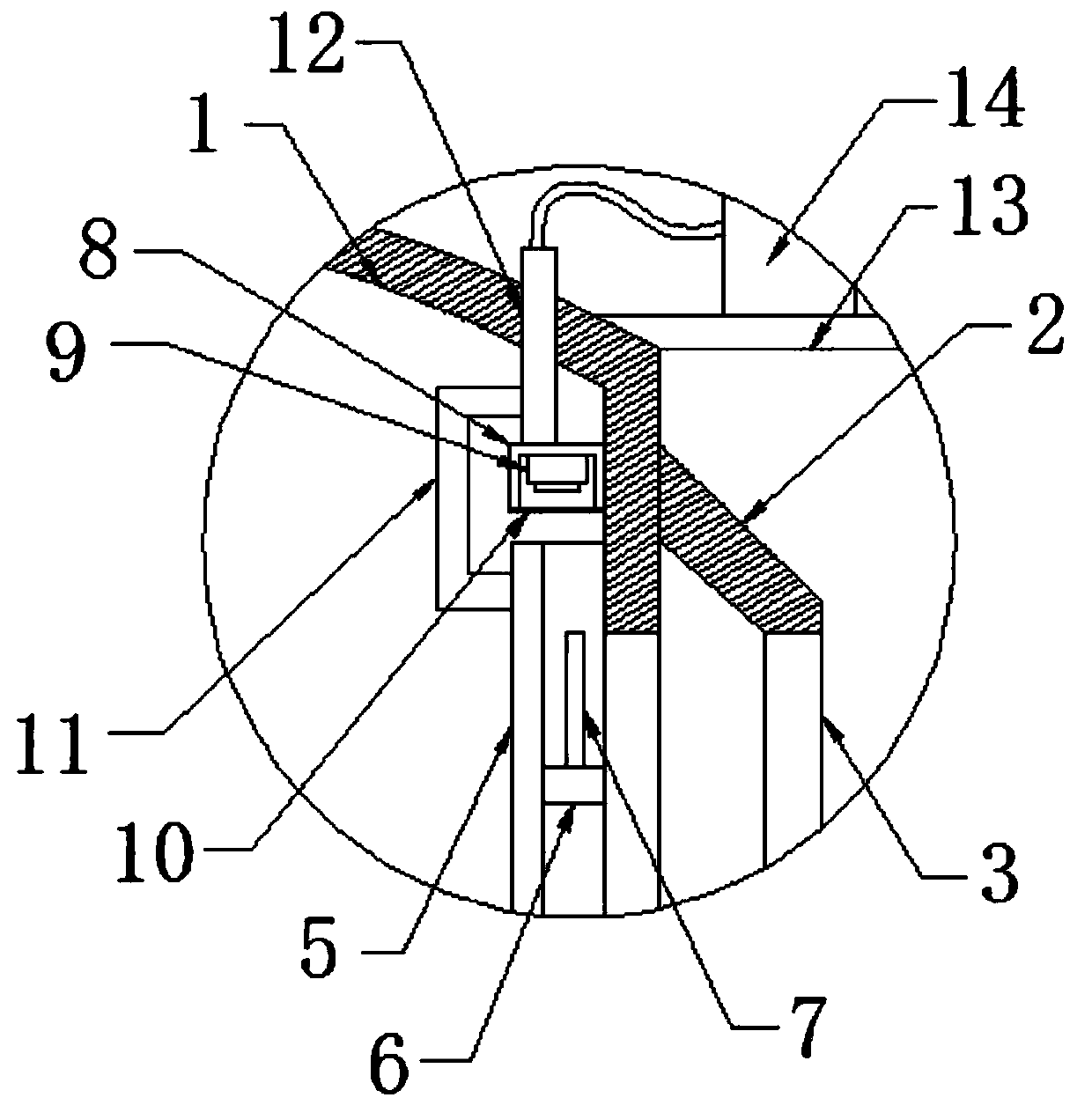

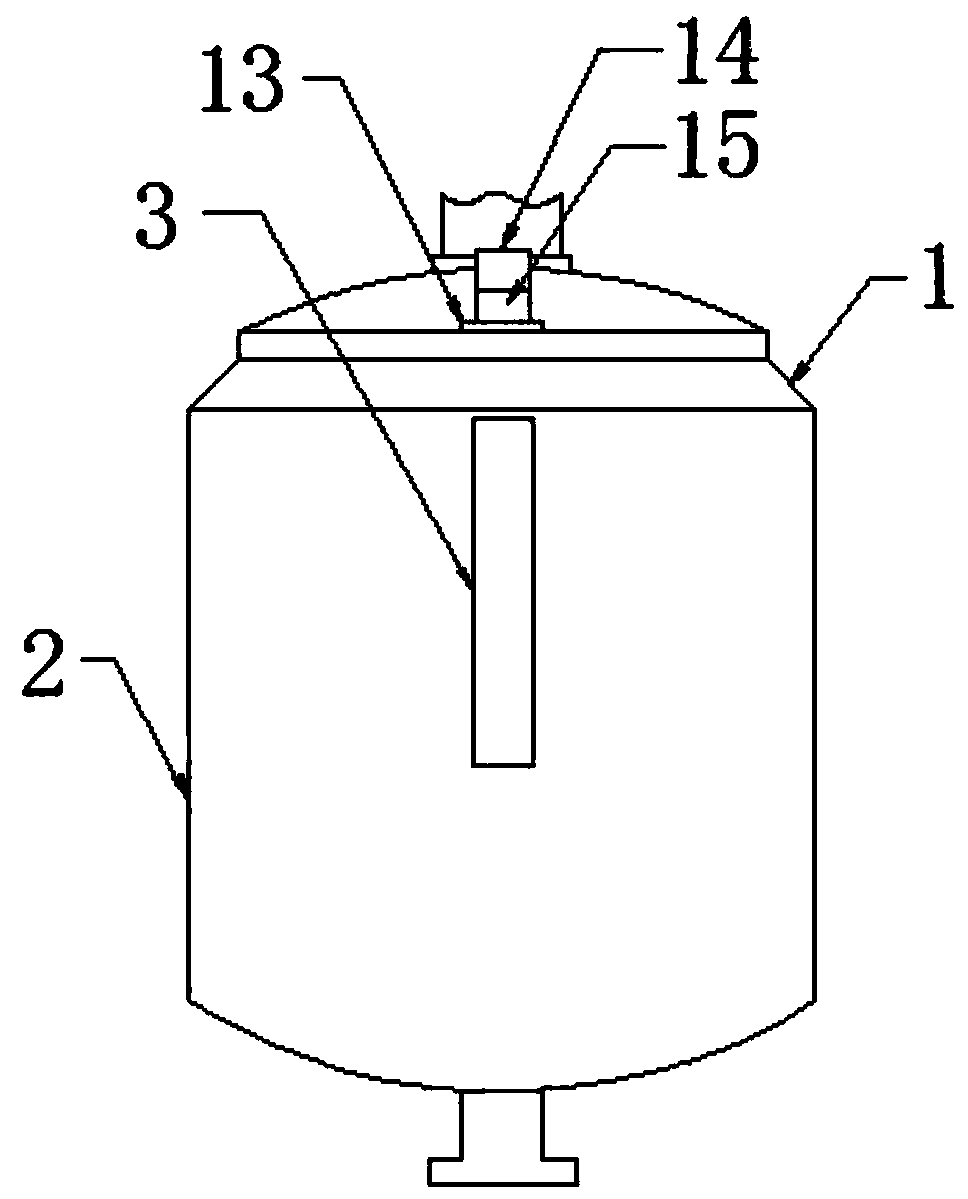

[0033] see Figure 1-5 , a high-efficiency reaction device for preparing polycarboxylic acid, comprising a reactor main body 1 and a floating block 6, the external fixed sleeve of the reactor main body 1 is provided with a heating mantle 2, the side wall of the reactor main body 1 and the heating mantle 2 The side walls of the reaction kettle body 1 are all dug with strip grooves, and the two strip grooves are located opposite each other. The interior of the strip groove is fixedly embedded with an observation plate 3, and the inner wall of the reaction kettle body 1 is fixedly connected with a strip arc plate 5, and the observation plate 3. The position of the strip-shaped arc plate 5 is directly opposite, and the left side of the inner wall of the strip-shaped arc plate 5 is embedded with a plurality of bulbs 17. The floating block 6 is placed on the inner side of the strip-shaped arc plate 5, and the center of the top of the floating block 6 is fixedly connected. Push rod 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com