Oil-cooled motor for calibration test

An oil-cooled, casing technology, applied in the field of oil-cooled motors, can solve the problems of increasing product development cycle, difficult simulation model correction, etc., and achieves the effect of convenient detection and adjustable flow pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

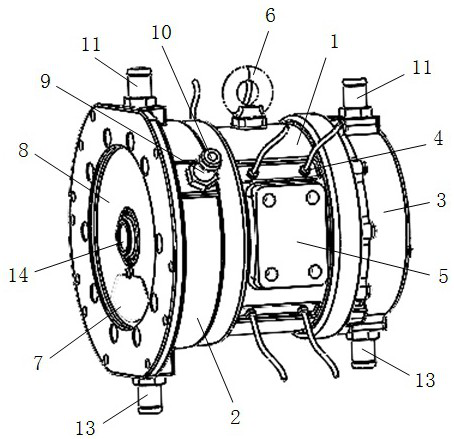

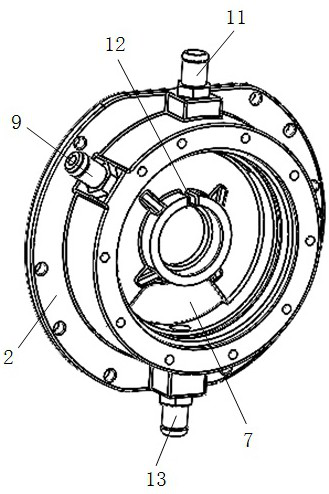

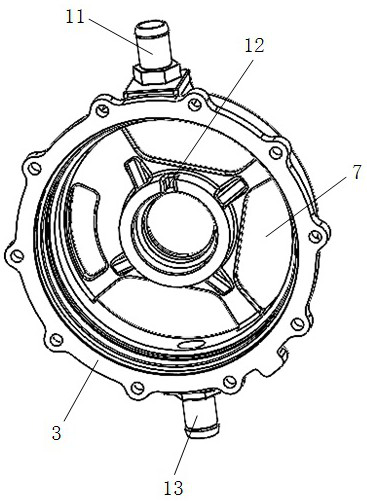

[0012] Such as figure 1 As shown, the present invention provides an oil-cooled motor for calibration testing, including a casing 1, a stator-rotor assembly installed in the casing 1, and a front end cover 2 and a rear end cover 3 that are hermetically connected to the casing 1 , wherein the stator and rotor assembly adopts the currently commonly used structural design, which belongs to the prior art and will not be described here.

[0013] A number of screw-type temperature sensors 4 are distributed on the cylindrical surface of the casing 1 for monitoring the temperature of various parts of the stator core; two fixed bosses 5 are symmetrically arranged on the cylindrical surface of the casing 1, and the fixed bosses on both sides 5 Use four screws to fix the oil-cooled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com