Blower main oil pump switching control circuit, starting-up control method and switching control method

A technology for controlling circuits and oil pump motors, which is applied in the direction of controlling multiple AC motors, pump control, AC motor control, etc. It can solve problems such as economic loss, unit failure to operate normally, and process system stop, so as to improve work efficiency and reduce The effect of reducing manpower and switching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

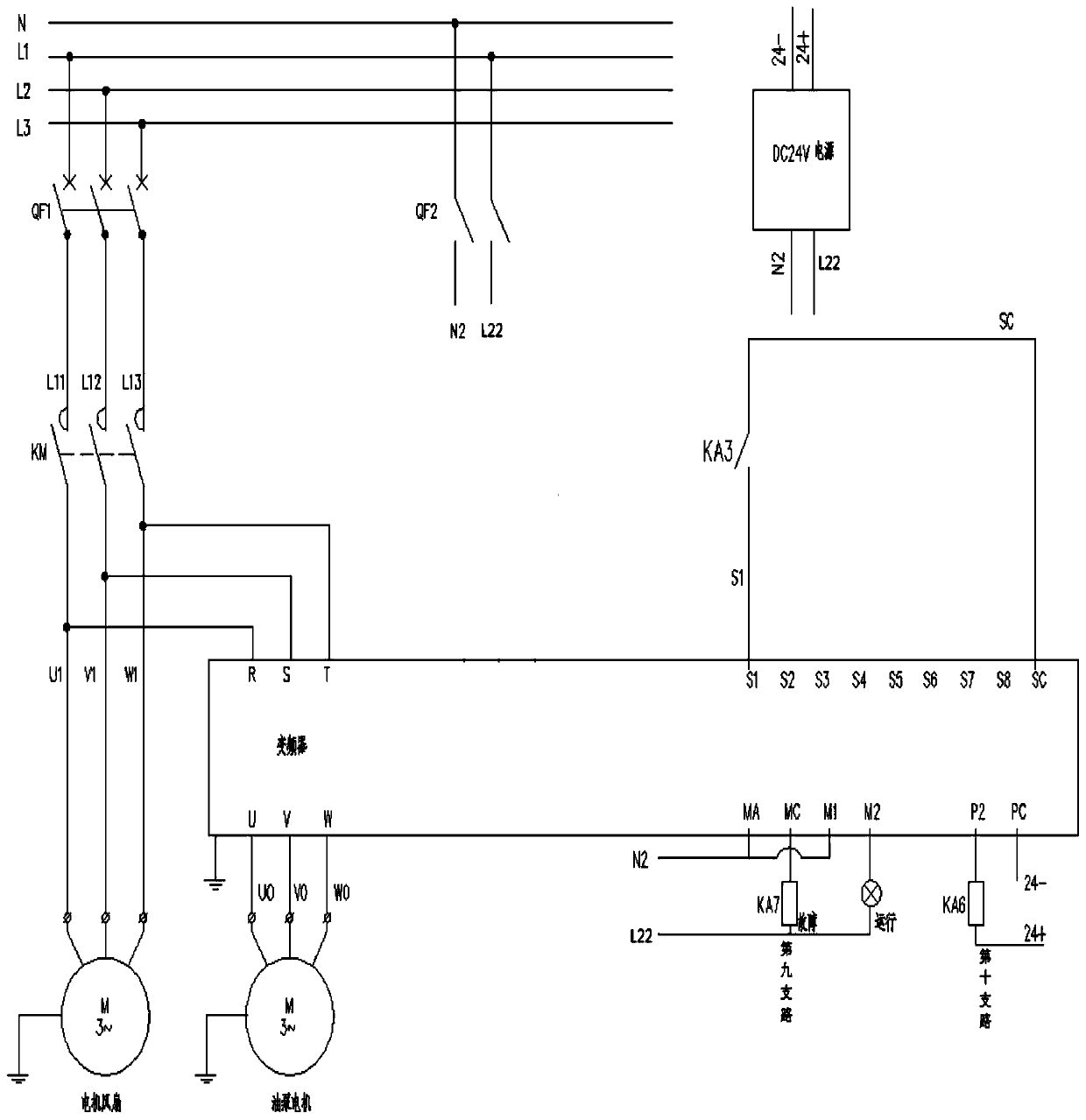

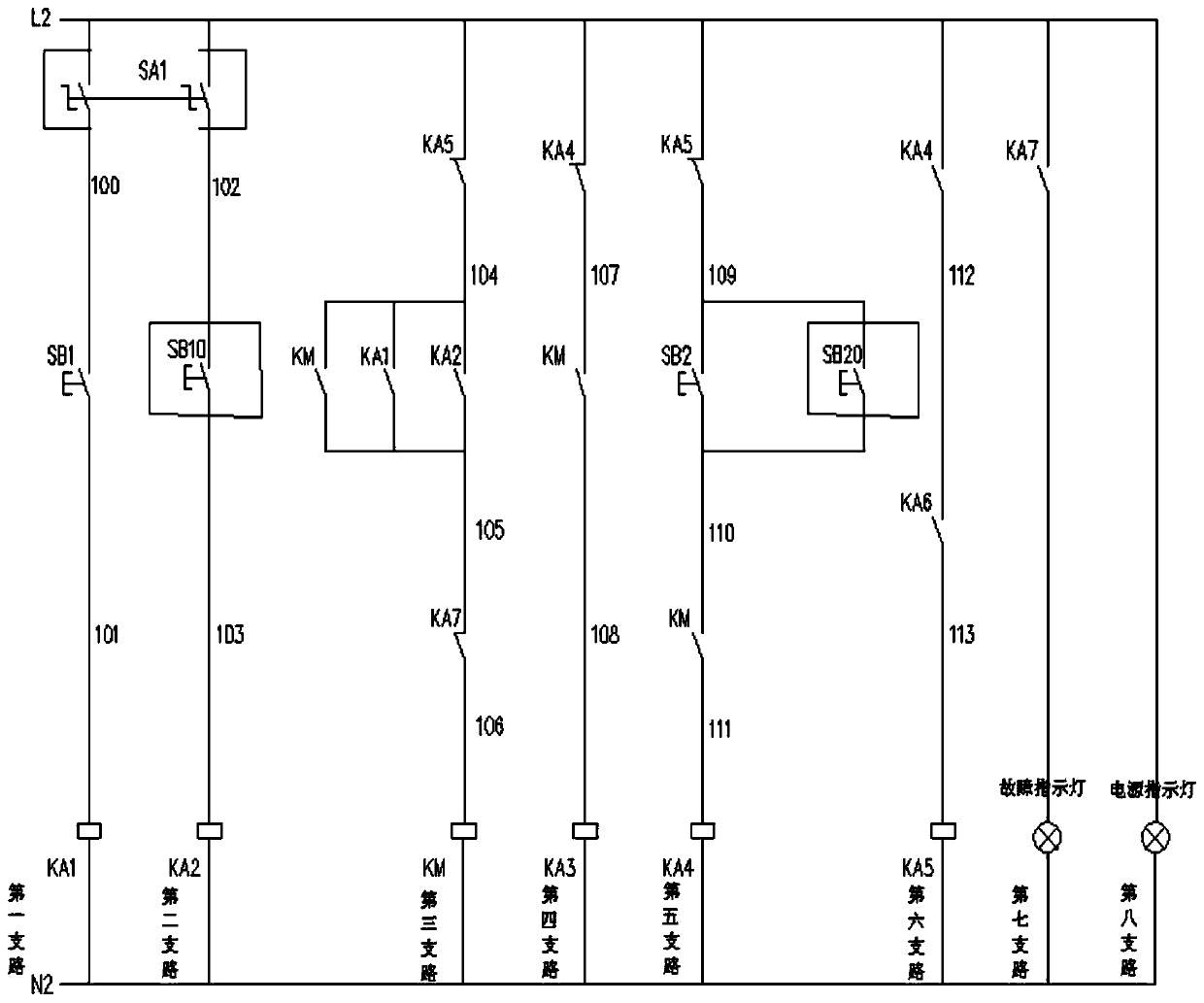

[0036] According to the above technical solution, the blower main oil pump switching control circuit of the present invention includes a main circuit and a control circuit connected to the main circuit. in:

[0037] like figure 1 As shown, the main circuit consists of low-voltage circuit breaker QF1, contactor KM, motor cooling fan and oil pump motor, and also includes a frequency converter; among them, the three-phase four-wire power supply (L1 phase, L2 phase, L3 phase, zero Line N) is respectively connected to the three upper ports of the low-voltage circuit breaker QF1, and the three lower ports (L11, L12, L13) of the low-voltage circuit breaker QF1 are connected to the three upper ports of the contactor KM; the three lower ports of the contactor KM Ports (U1, V1, W1) are respectively connected to the inverter input (R, S, T) and the motor cooling fan, and the inverter output (U, V, W) is connected to the oil pump motor.

[0038] In the above main circuit, the low-voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com