Three-level laminated busbar for suppressing stray inductance

A technology of stacking busbars and stray inductance, which is applied in the modification of power electronics, electrical components, and output power conversion devices, etc., can solve the problems of high stray inductance of the commutation circuit, time-consuming and laborious disassembly and handling, and many parts and components. , to achieve the effect of reducing stray inductance and maximizing the overall output capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

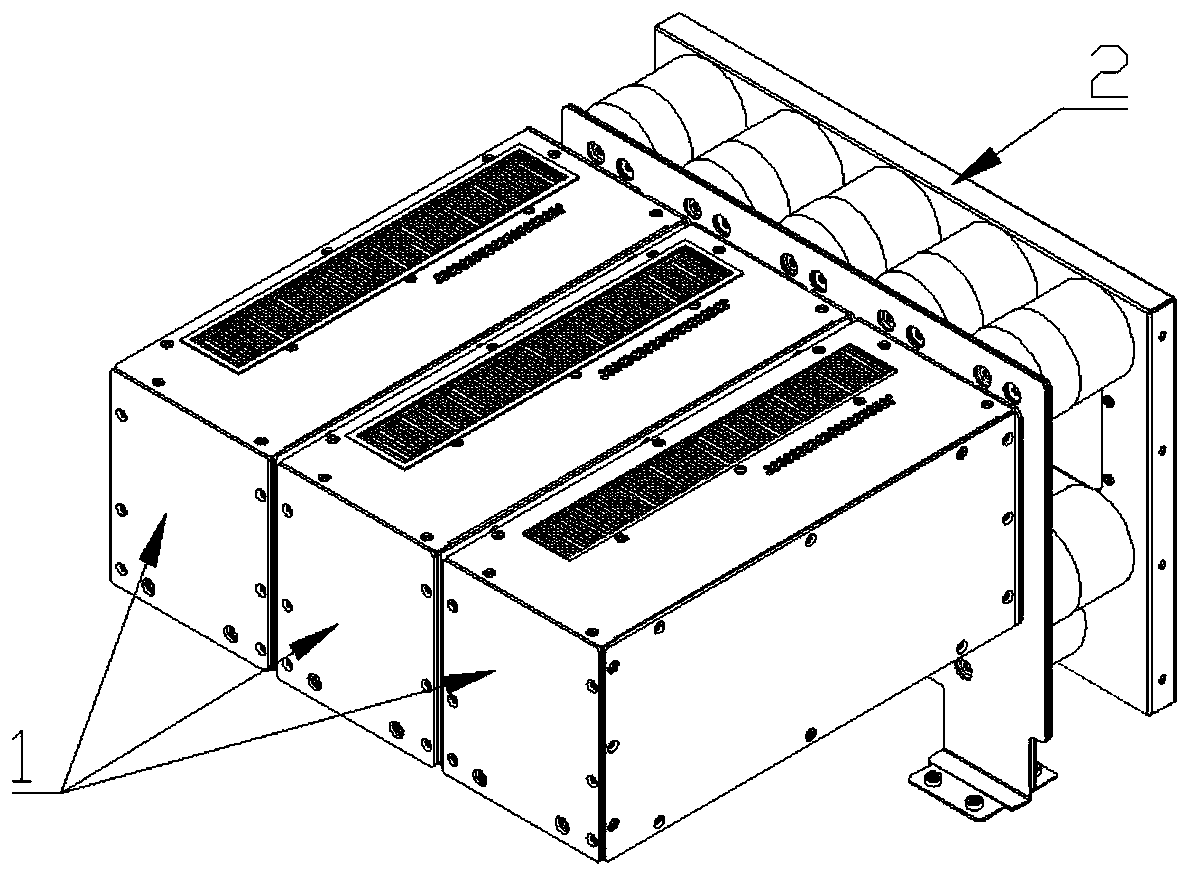

[0026] Such as figure 1 As shown, the three-level laminated busbar described in the present invention adopts the structure independently designed by A, B, C three-phase power module 1 and DC support capacitor module 2, and the A, B, C three-phase power module is Same design.

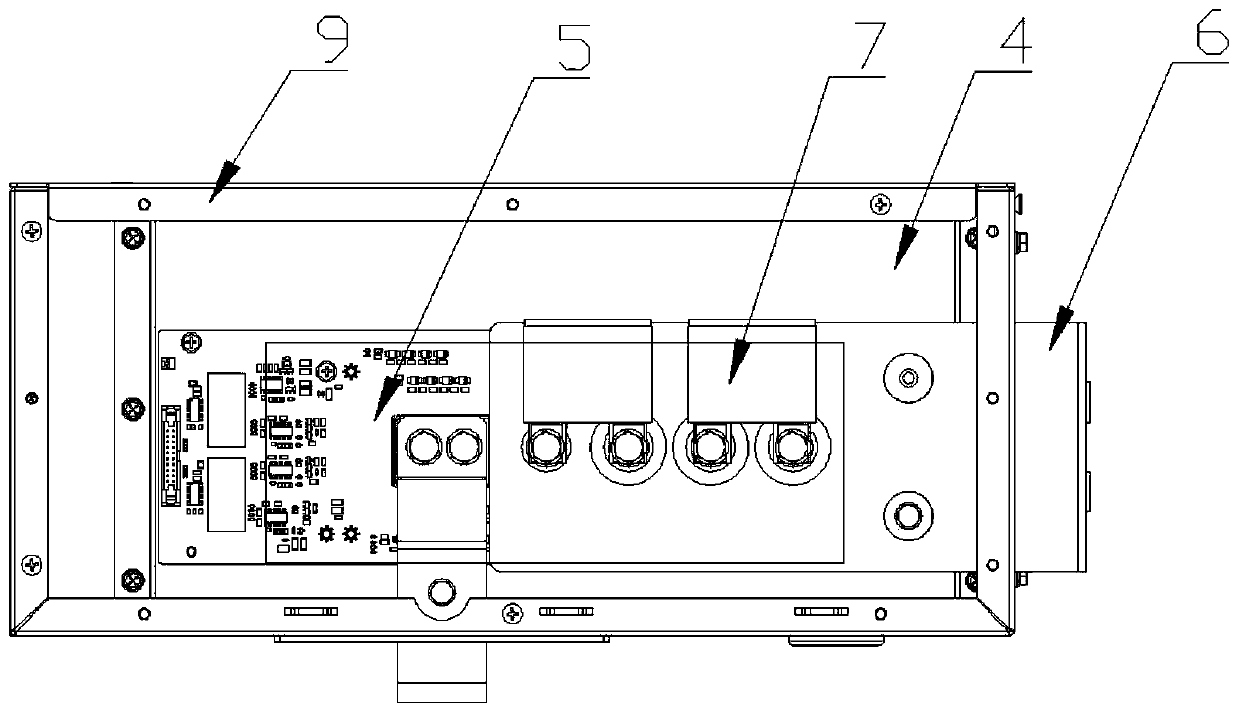

[0027] The level of the three-level layer adopts a seven-layer pressing design. From the top layer to the bottom layer, they are: insulating layer, positive layer, insulating layer, neutral layer, insulating layer, negative layer, and insulating layer.

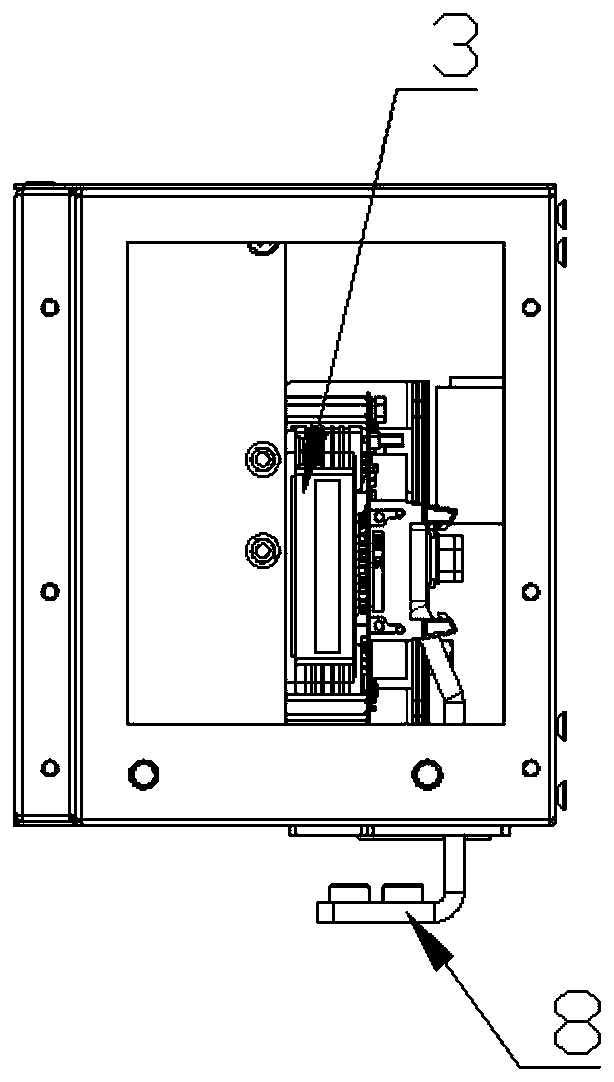

[0028] Such as figure 2 , image 3 and Figure 4 As shown, the A, B, and C three-phase power module 1 is designed as a sheet metal frame 9, with a power module stacked busbar 6 inside the frame, an air-cooled radiator 4 at the bottom, and a power module stacked busbar 6 from the left From the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com