Disk-type iron core and disk-type motor

An iron core and disc type technology, which is applied in the field of disc iron core and disc motor, can solve problems such as difficulties and increase of coil off-line, and achieve the effect of reducing assembly difficulty, facilitating off-line, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The core of the present invention is to provide a disk-type iron core and a disk-type motor, so as to reduce the difficulty of assembling the coil and improve the assembly efficiency.

[0029] In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

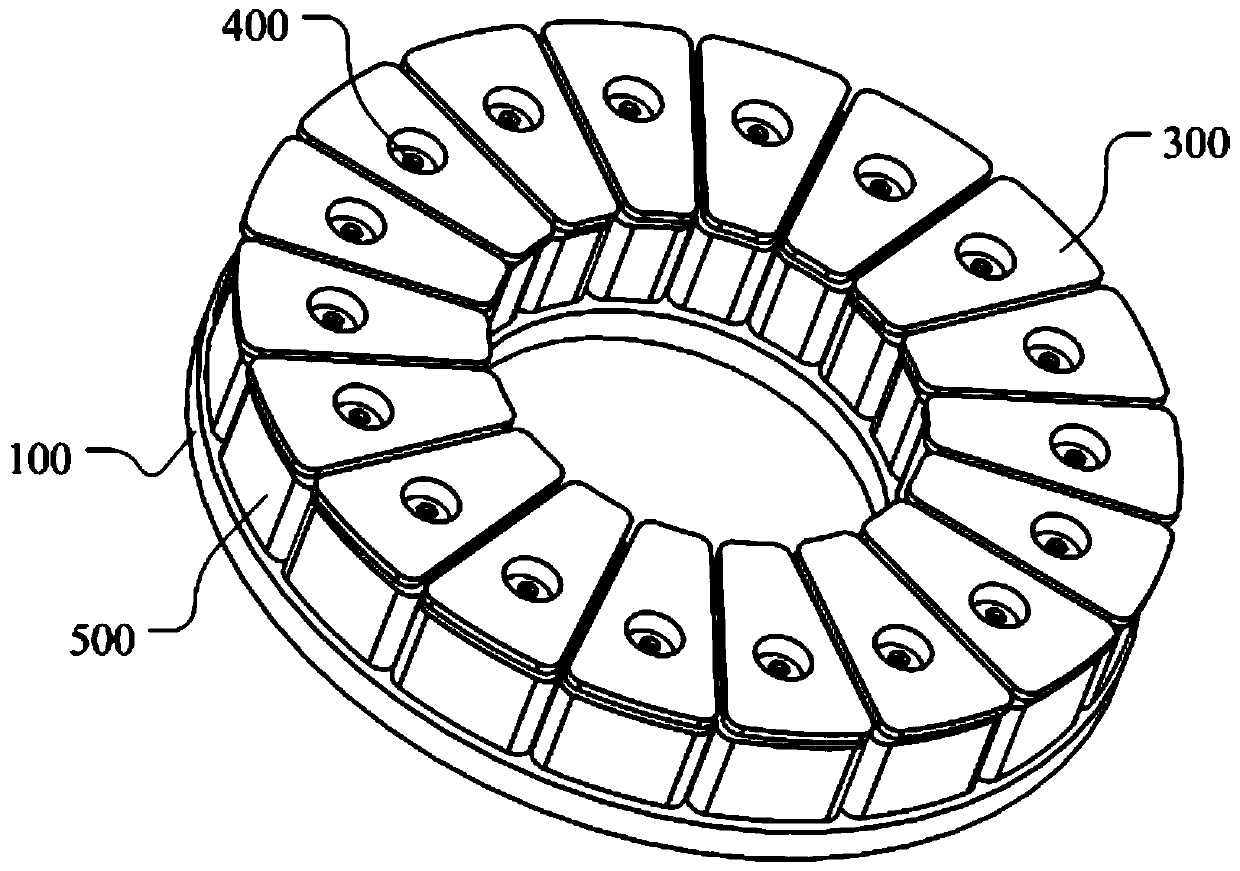

[0030] see Figure 1 to Figure 5 , a disc core in an embodiment of the present invention, comprising:

[0031] A disc-shaped iron core base 100;

[0032] A plurality of first iron core teeth 200, the plurality of first iron core teeth 200 are arranged on the end surface of the iron core base 100 along the circumferential direction, and there are first grooves 201 between adjacent first iron core teeth 200; as well as

[0033] A plurality of second iron core teeth 300, each second iron co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com