A grid aisle of an automatic vending machine

A technology for vending machines and cargo lanes, which is applied to coin-free or similar appliances, coin-operated equipment for distributing discrete items, and coin-operated equipment for distributing discrete items, etc. , many commodity restrictions, etc., to achieve the effect of not easy to jam, ensure reliability, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

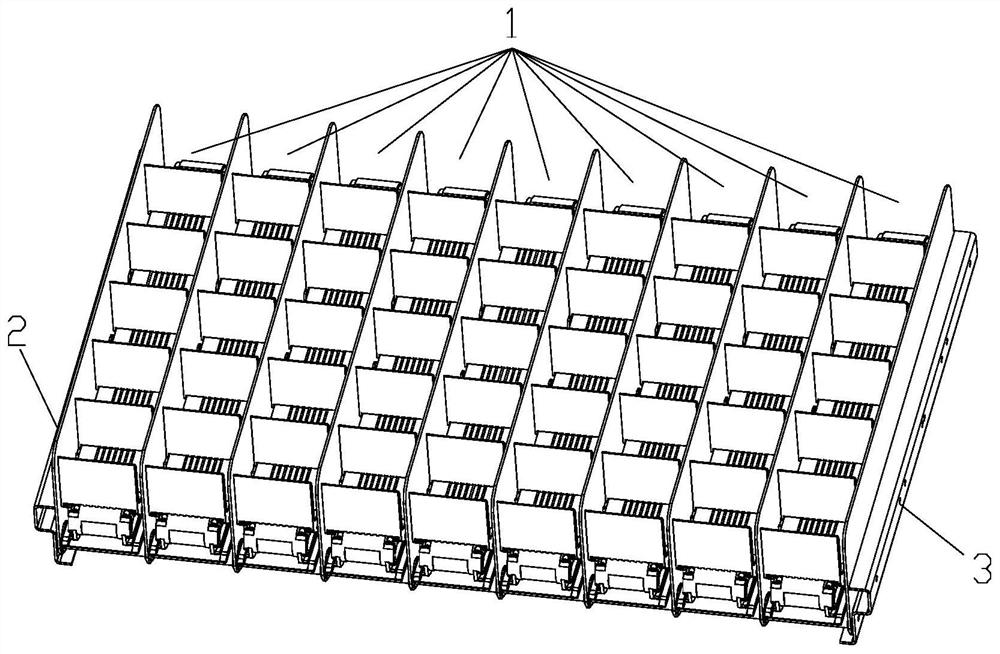

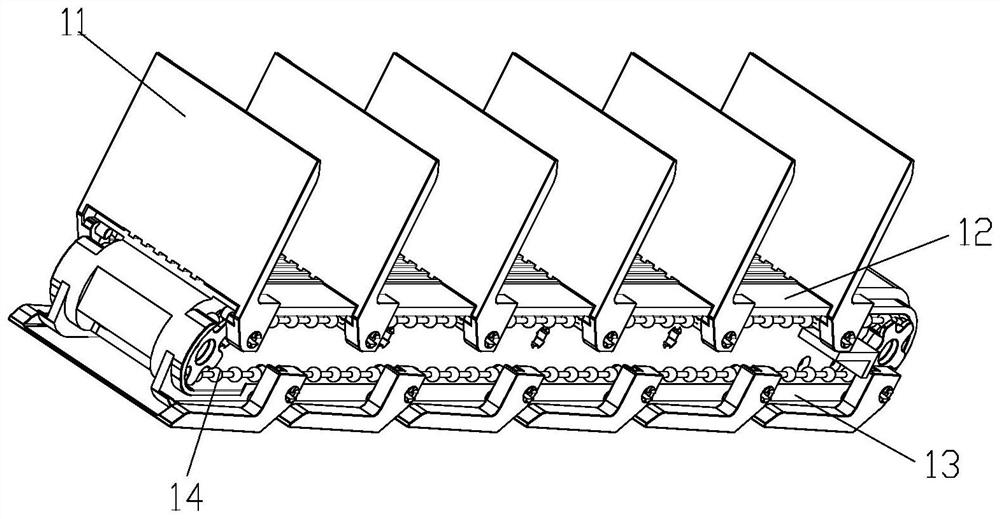

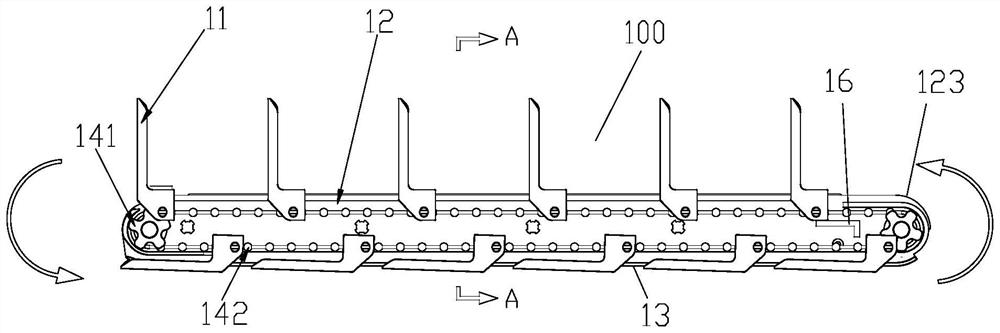

[0027] see figure 1 and figure 2 , the lattice cargo lane shown in the figure is a specific embodiment of the present invention, the main body of each cargo lane 1 is a strip-shaped cargo lane bottom plate 12, and each cargo lane 1 partially passes through the cargo lane bottom plate 12 Several bottom plates 11 are separated to form several storage compartments 100, and the same type of goods are placed inside the space of the storage compartments 100 on the same cargo lane 1, and all the push plates 11 of the same cargo lane pass through the circular transmission mechanism 14 along the cargo lane The bottom plate 12 pushes the goods in the storage compartment space to move forward, and drop into the delivery channel of the automatic vending machine from the front end of the goods channel 1 one by one. Multiple sets of cargo lanes 1 are arranged side by side on the same level of pallets, and are fixed inside the body of the vending machine through brackets 3. Adjacent cargo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com