A combined anchor for fiber-reinforced composite cable and its preparation method

A composite material and fiber reinforced technology, applied in the direction of building reinforcements, buildings, building components, etc., can solve the problems of pinch breakage, poor anchorage stability, and large anchorage size, so as to reduce the size of the anchorage and control the cost. , the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

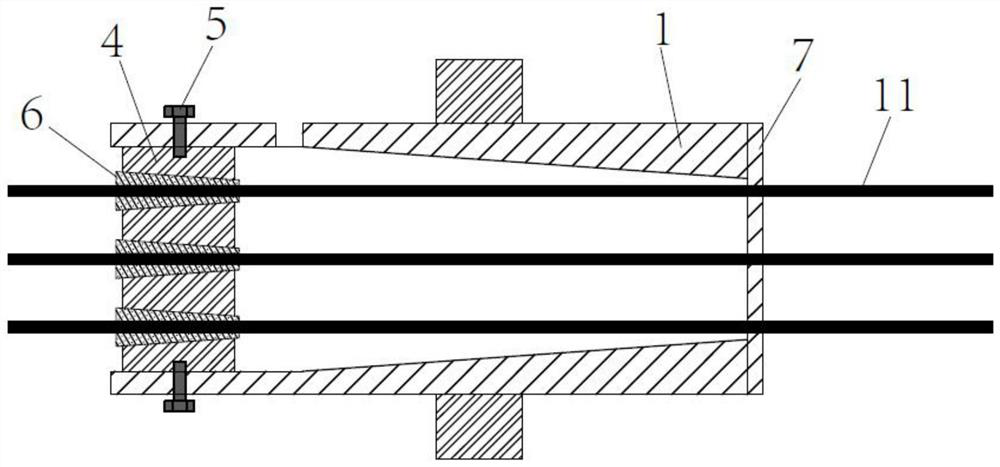

[0028] refer to figure 1 with figure 2 As shown, an embodiment of the combined anchor for the fiber reinforced composite cable of the present invention includes a steel sleeve 1, an anchor plate and a limit bolt, and the sleeve cavity of the steel sleeve is divided into straight sections 2 and the oblique section 3, the anchor plate 4 is installed at the tail end of the steel sleeve and is located in the straight section, the straight section has the guiding function of guiding the anchor plate to move longitudinally along the steel sleeve, and the steel sleeve corresponding to the straight section The wall of the cylinder is provided with a limit pin 5, which is used to fix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com