Fabricated special-shaped beam column joint

A beam-column node and assembled technology, applied in the direction of architecture and building structure, can solve the problems of reducing the building area and affecting the placement of functional furniture in the room, so as to reduce the construction process, improve the application value and scientific research benefits, The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

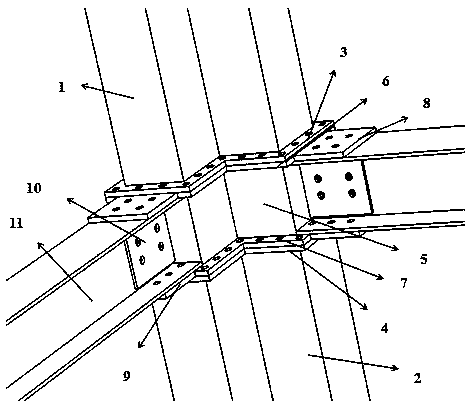

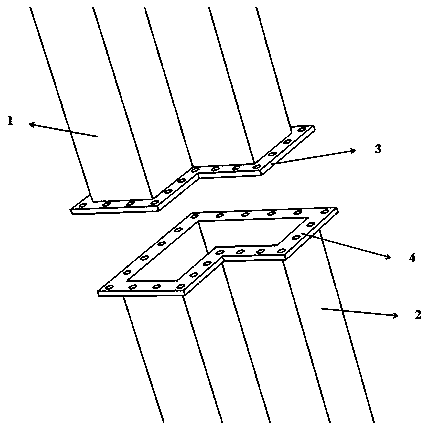

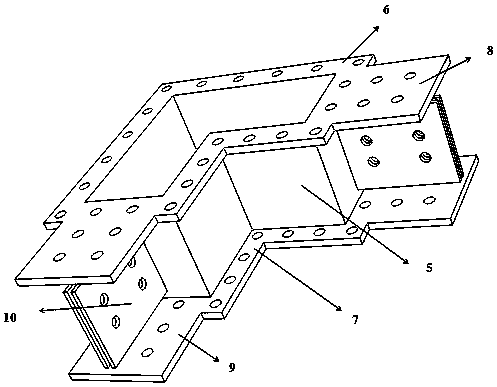

[0021] Example 1: as Figure 1-Figure 4 As shown, an assembled special-shaped beam-column joint includes a special-shaped upper column 1, a special-shaped lower column 2, an upper flange 3, a lower flange 4, a column seat 5, an upper flange plate 6 on the column seat, and a lower column seat. Flange 7, upper reinforcing ring plate 8 of column base, 9 reinforcing ring plate below column base, 10 sticking plate extending inside the column base, 11 H-shaped steel beam;

[0022] Among them, the upper and lower ends of the column seat 5 are welded to set the upper flange plate 6 of the column seat and the lower flange plate 7 of the column seat. The lower flange 4 welded at the end of the lower column 2 and the lower flange 7 of the column seat are connected by high-strength bolts, and the upper flange 6 of the column seat is provided with an integrated upper column reinforcing ring plate 8 on the same plane to pass the high-strength bolts. The upper flange of the H-shaped steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com